Both Vectran™ and Aramid yarns are known for being resilient materials used for specialized products. They each have varying degrees of creep resistance, abrasion resistance, high tensile strength, excellent flex/fold characteristics, long term dimensional stability and exceptional property retention at high temperatures. These yarns are extremely durable and often used to protect people and products.

Read more- By Eric Shippee

- 10/27/17

- 0 Comments

- By Steve Zande

- 09/26/17

- 2 Comments

Vectran™ is a manufactured fiber used to make specialty fabric and typically only those with a specific product application know much about it. This multifilament yarn is spun from a liquid crystal polymer (LCP) and is the only commercially available melt-spun LCP fiber in the world. Vectran™ fiber presents exceptional strength and rigidity because the material is five times stronger than steel and ten times stronger than aluminum. There are no real alternatives when it comes to working with Vectran™ as the qualities it brings to the table are distinctive and highly beneficial.

Read more- By Eric Shippee

- 09/07/17

- 0 Comments

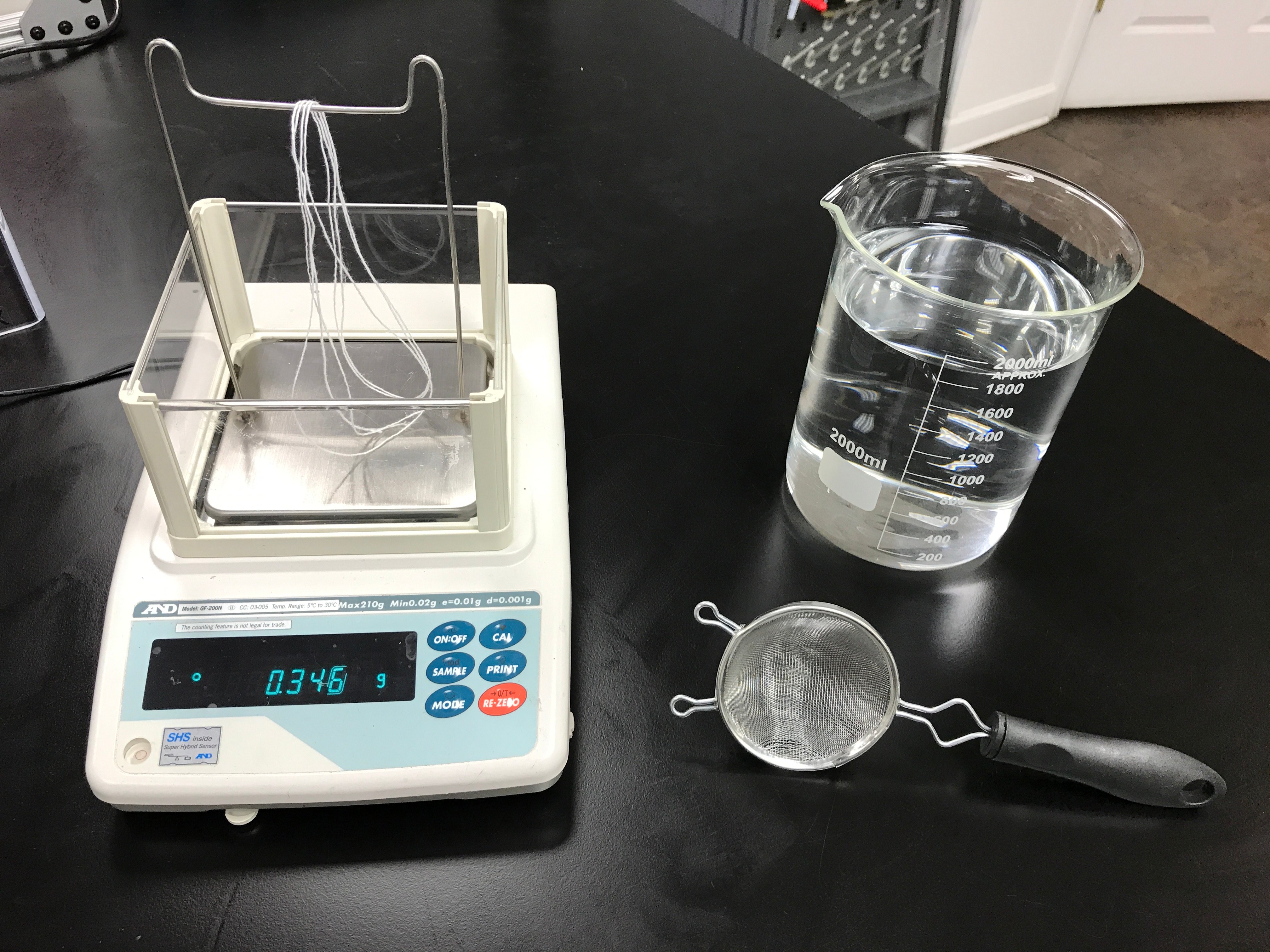

When yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

Read more- By Torry Losch

- 07/27/17

- 0 Comments

In part one of this series, I talked about how to understand polyester pricing swings and why rising costs and a dynamic market has thrust the industry into a volatile time. In part two, I touched on understanding market, spot and indexed pricing. In this post, I’ll focus on index formulas, particularly once a supplier and client decide to index a price, what does it look like? In general, designing a simple index formula is the best strategy. The difficult part is agreeing to the finer details up front. Both parties must carefully consider the following aspects.

Read more- By Service Thread

- 07/17/17

- 0 Comments

- By Torry Losch

- 06/13/17

- 2 Comments

In part one of Service Thread’s blog series on polyester yarn pricing, I discussed the reason for the unpredictable cost swings with polyester yarn pricing. In addition to understanding the global dynamics that effect these swings, it is also important to understand the pricing strategies used.

Read more- By Torry Losch

- 06/07/17

- 0 Comments

I’ve been in the industrial yarn business for 21 years and haven’t seen anything quite like the current polyester pricing situation. If you buy or sell synthetic yarns, I’m sure that you feel the same way. The fast pace of the modern business environment has impacted every market’s volatility, even the very mature ones (read “old textile businesses”).

Read more- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read more- By Dane Hatcher

- 03/04/16

- 0 Comments

If your top thread is shredding or coming apart while sewing, this could indicate a common issue with the process. When the sewing machine pushes the needle through the material, it grabs the thread with a hook (or “looper”), while the needle rises back up. If there is a problem with this step it causes the thread to peel back, shred, break, flake, or not even get caught at all.

Read moreVectran™ Vs. Aramid

- By Eric Shippee

- 10/27/17

- 0 Comments

Both Vectran™ and Aramid yarns are known for being resilient materials used for specialized products. They each have varying degrees of creep resistance, abrasion resistance, high tensile strength, excellent flex/fold characteristics, long term dimensional stability and exceptional property retention at high temperatures. These yarns are extremely durable and often used to protect people and products.

Read moreWhat is Vectran™?

- By Steve Zande

- 09/26/17

- 2 Comments

Vectran™ is a manufactured fiber used to make specialty fabric and typically only those with a specific product application know much about it. This multifilament yarn is spun from a liquid crystal polymer (LCP) and is the only commercially available melt-spun LCP fiber in the world. Vectran™ fiber presents exceptional strength and rigidity because the material is five times stronger than steel and ten times stronger than aluminum. There are no real alternatives when it comes to working with Vectran™ as the qualities it brings to the table are distinctive and highly beneficial.

Read moreWhen yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

Read moreIn part one of this series, I talked about how to understand polyester pricing swings and why rising costs and a dynamic market has thrust the industry into a volatile time. In part two, I touched on understanding market, spot and indexed pricing. In this post, I’ll focus on index formulas, particularly once a supplier and client decide to index a price, what does it look like? In general, designing a simple index formula is the best strategy. The difficult part is agreeing to the finer details up front. Both parties must carefully consider the following aspects.

Read morePolyester Yarn Price Update Part Two: Understanding Market, Spot and Indexed Pricing

- By Torry Losch

- 06/13/17

- 2 Comments

In part one of Service Thread’s blog series on polyester yarn pricing, I discussed the reason for the unpredictable cost swings with polyester yarn pricing. In addition to understanding the global dynamics that effect these swings, it is also important to understand the pricing strategies used.

Read moreI’ve been in the industrial yarn business for 21 years and haven’t seen anything quite like the current polyester pricing situation. If you buy or sell synthetic yarns, I’m sure that you feel the same way. The fast pace of the modern business environment has impacted every market’s volatility, even the very mature ones (read “old textile businesses”).

Read moreWhat is ASTM D4974? Hot Air Shrinkage Test for Yarn & Cord Explained

- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read moreIf your top thread is shredding or coming apart while sewing, this could indicate a common issue with the process. When the sewing machine pushes the needle through the material, it grabs the thread with a hook (or “looper”), while the needle rises back up. If there is a problem with this step it causes the thread to peel back, shred, break, flake, or not even get caught at all.

Read more