- By Eric Shippee

- 01/19/18

- 0 Comments

Industrial yarn is designed and engineered to be incorporated into products where oftentimes, a functional requirement supersedes aesthetic considerations. Used by non-apparel industry product manufacturers, industrial yarns are typically a component part of a product to enhance the strength, durability, performance and other high-value properties of the product.

Industrial yarn is designed and engineered to be incorporated into products where oftentimes, a functional requirement supersedes aesthetic considerations. Used by non-apparel industry product manufacturers, industrial yarns are typically a component part of a product to enhance the strength, durability, performance and other high-value properties of the product.

- By Eric Shippee

- 12/22/17

- 0 Comments

- By Eric Shippee

- 07/19/17

- 1 Comment

- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read moreOlder Posts

Industrial yarn is designed and engineered to be incorporated into products where oftentimes, a functional requirement supersedes aesthetic considerations. Used by non-apparel industry product manufacturers, industrial yarns are typically a component part of a product to enhance the strength, durability, performance and other high-value properties of the product.

Industrial yarn is designed and engineered to be incorporated into products where oftentimes, a functional requirement supersedes aesthetic considerations. Used by non-apparel industry product manufacturers, industrial yarns are typically a component part of a product to enhance the strength, durability, performance and other high-value properties of the product.

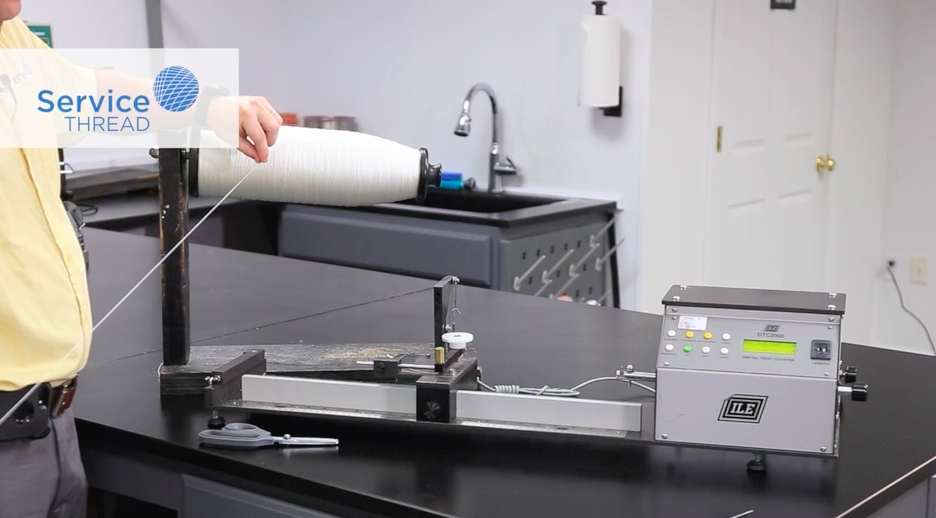

What is ASTM D4974? Hot Air Shrinkage Test for Yarn & Cord Explained

- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read more