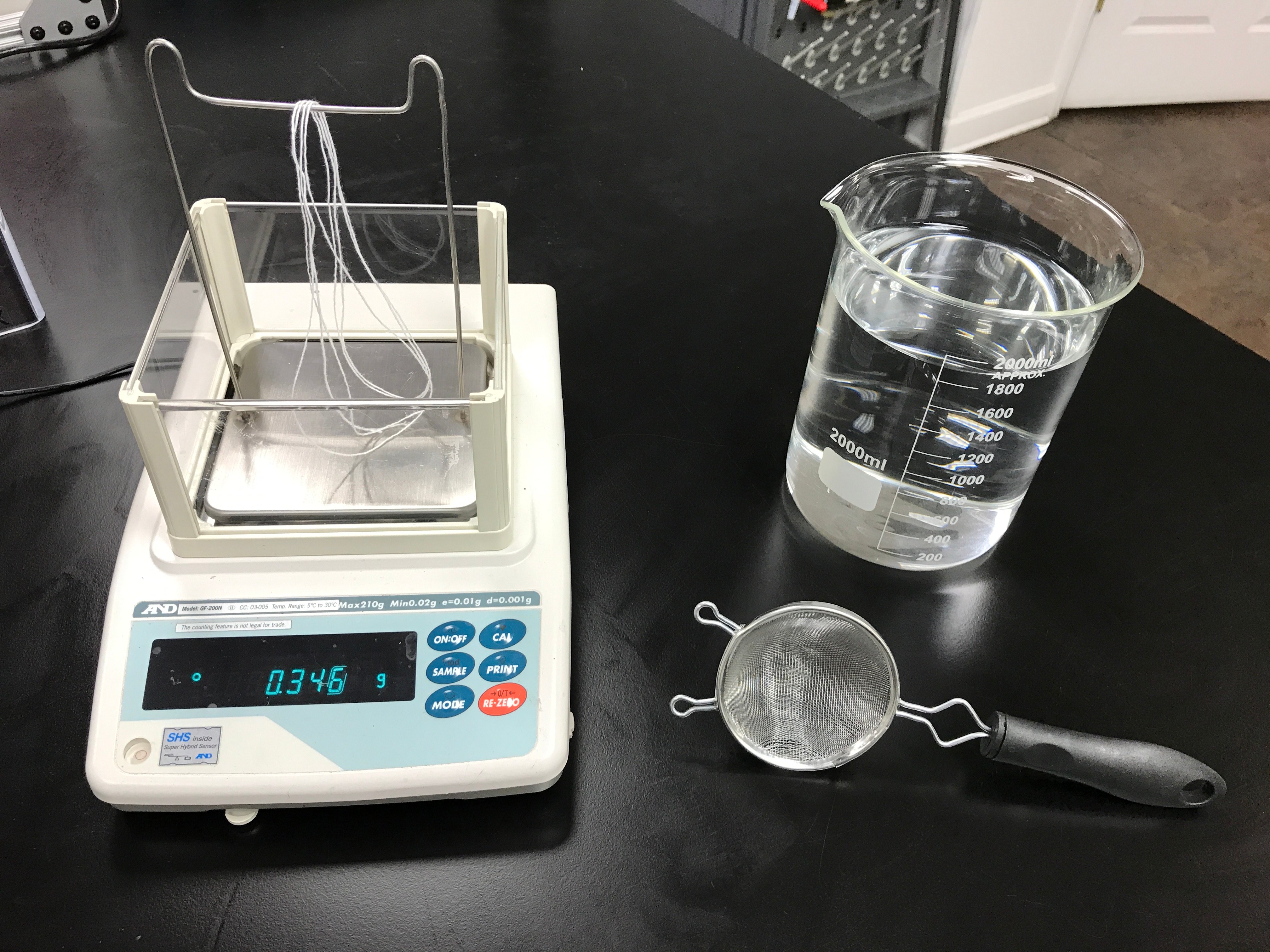

As the textile industry faces rising scrutiny over chemical safety and environmental impact, one group of substances has come under particular fire: PFAS. Long valued for their ability to impart water- and stain-resistant properties, these “forever chemicals” are now being phased out across global markets. For manufacturers of high-performance yarns, this raises a critical challenge: how to maintain non-wicking functionality without PFAS.

Read morePFAS-Free Non-Wicking Yarn Treatments: A Safer Alternative for High-Performance Textiles

- By Steve Zande

- 06/27/25

- Wire and Cable, Wicking Test, Waterblocking, Industrial Yarn, Polyester

- 0 Comments

- By Jay Todd

- 02/02/25

- 0 Comments

- By Steve Zande

- 07/27/18

- 0 Comments

When you are searching for a fiber or yarn for specific application requirements, there are many options to choose from. Meta-aramid and para-aramid yarns and threads are two popular choices for heat resistance and superior tensile strength.

Read more- By Eric Shippee

- 04/03/18

- 0 Comments

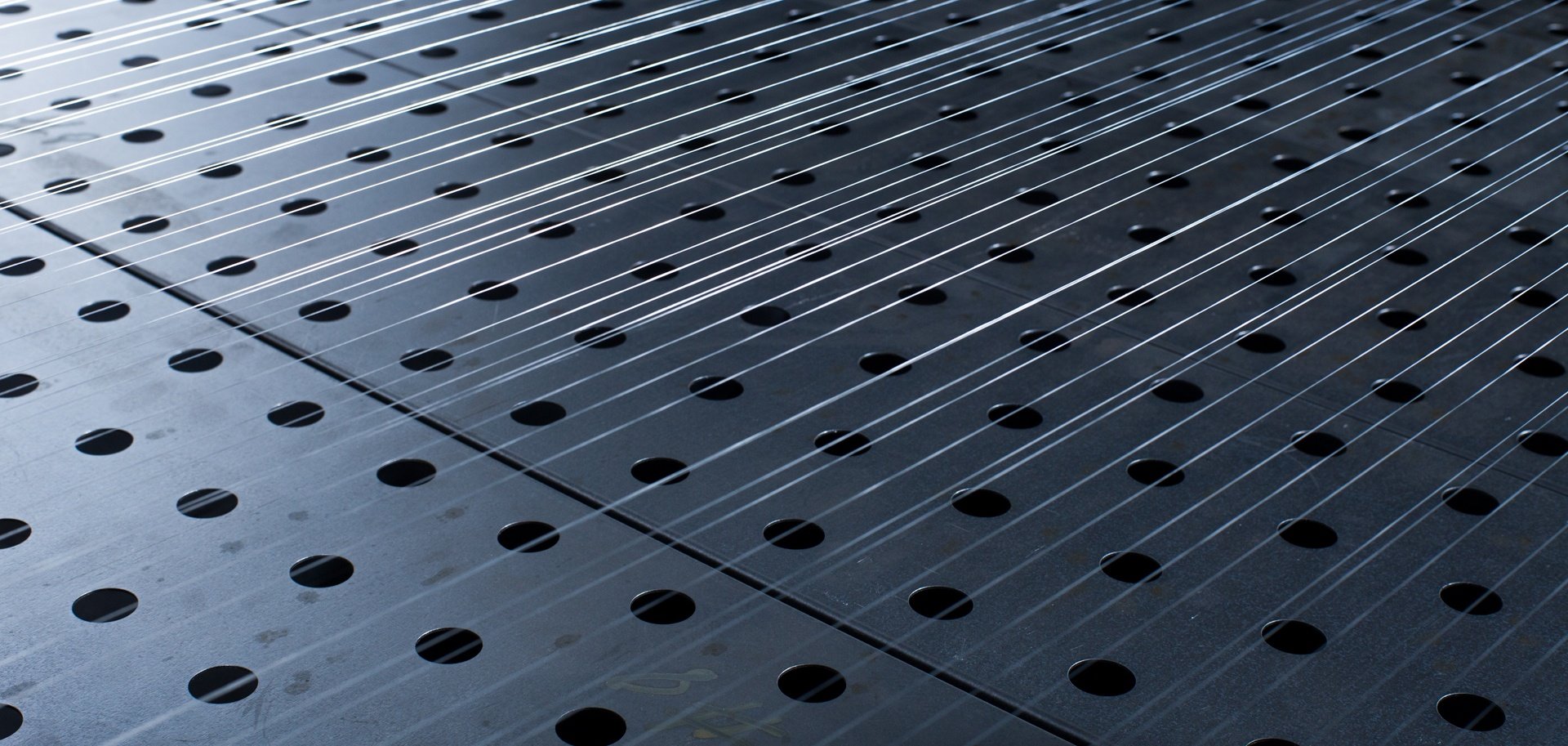

The critical reason for a wire and cable manufacturer to use a water blocking treatment in their product is to prevent access and dissipation of water and moisture throughout the cable. When deciding on which treatment to use (i.e. gel, yarn, or powder based) in your cable, it’s important to consider the advantages and disadvantages of each application method.

- By Steve Zande

- 03/20/18

- 0 Comments

Aramid fiber is best known by the trademark name DuPont™ Kevlar® and offers many unique and beneficial properties. With aramid raw material costs between five and thirty times the cost of nylon or polyester, many manufacturers look for ways to save when aramids are required for their application. What seems on the surface like an easy question is a lot more complicated than you might think. So, what are some of the factors that contribute to the total cost of industrial aramid yarn or thread?

Read more- By Eric Shippee

- 09/07/17

- 0 Comments

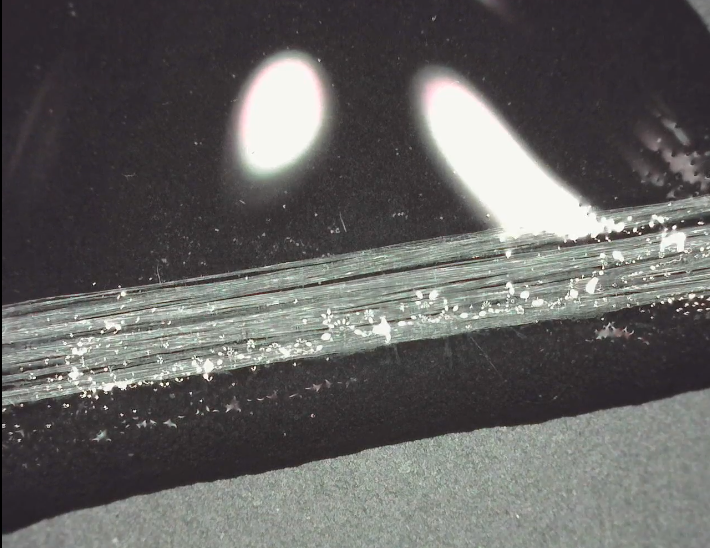

When yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

Read more- By Eric Shippee

- 11/18/16

- 0 Comments

The critical reason for using waterblocking fiber in wire and cable manufacturing is to prevent access and dissipation of water and moisture throughout the cable. In fact, water is the most likely cause of premature failure for cable and electrical equipment. There are two common ways water and moisture finds its way into a cable:

Read morePFAS-Free Non-Wicking Yarn Treatments: A Safer Alternative for High-Performance Textiles

- By Steve Zande

- 06/27/25

- Wire and Cable, Wicking Test, Waterblocking, Industrial Yarn, Polyester

- 0 Comments

As the textile industry faces rising scrutiny over chemical safety and environmental impact, one group of substances has come under particular fire: PFAS. Long valued for their ability to impart water- and stain-resistant properties, these “forever chemicals” are now being phased out across global markets. For manufacturers of high-performance yarns, this raises a critical challenge: how to maintain non-wicking functionality without PFAS.

Read moreOlder Posts

When you are searching for a fiber or yarn for specific application requirements, there are many options to choose from. Meta-aramid and para-aramid yarns and threads are two popular choices for heat resistance and superior tensile strength.

Read moreAdvantages And Disadvantages Of Various Water Blocking Treatments

- By Eric Shippee

- 04/03/18

- 0 Comments

The critical reason for a wire and cable manufacturer to use a water blocking treatment in their product is to prevent access and dissipation of water and moisture throughout the cable. When deciding on which treatment to use (i.e. gel, yarn, or powder based) in your cable, it’s important to consider the advantages and disadvantages of each application method.

Aramid fiber is best known by the trademark name DuPont™ Kevlar® and offers many unique and beneficial properties. With aramid raw material costs between five and thirty times the cost of nylon or polyester, many manufacturers look for ways to save when aramids are required for their application. What seems on the surface like an easy question is a lot more complicated than you might think. So, what are some of the factors that contribute to the total cost of industrial aramid yarn or thread?

Read moreWhen yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

Read moreThe critical reason for using waterblocking fiber in wire and cable manufacturing is to prevent access and dissipation of water and moisture throughout the cable. In fact, water is the most likely cause of premature failure for cable and electrical equipment. There are two common ways water and moisture finds its way into a cable:

Read more