As the textile industry faces rising scrutiny over chemical safety and environmental impact, one group of substances has come under particular fire: PFAS. Long valued for their ability to impart water- and stain-resistant properties, these “forever chemicals” are now being phased out across global markets. For manufacturers of high-performance yarns, this raises a critical challenge: how to maintain non-wicking functionality without PFAS.

Read morePFAS-Free Non-Wicking Yarn Treatments: A Safer Alternative for High-Performance Textiles

- By Steve Zande

- 06/27/25

- Wire and Cable, Wicking Test, Waterblocking, Industrial Yarn, Polyester

- 0 Comments

- By Steve Zande

- 04/23/25

- 0 Comments

Recent developments in U.S. trade policy have once again put a spotlight on the vulnerability of supply chains that rely heavily on imported materials—particularly from China. With proposed tariff hikes targeting a wide range of goods, including industrial textiles and raw materials, manufacturers are facing increased pressure to find reliable, cost-effective alternatives closer to home.

Read more- By Steve Zande

- 12/13/24

- 0 Comments

Polyester yarns are fundamental to the performance and longevity of a wide range of industrial products. From hose reinforcement to binder yarns for fiber optic cables, tire cords, and industrial fabrics, the success of these applications hinges on achieving the right balance of mechanical properties. Among these critical properties, break strength, elongation, and shrinkage play pivotal roles. Each property serves a distinct purpose, and optimizing one can have a cascading effect on the others.

Read more- By Steve Zande

- 09/05/23

- 0 Comments

The recent news of Alfa Group's decision to close its filament polyester production plant in Mexico has sent shockwaves throughout the industry. Companies that once relied on Akra's products are now faced with the daunting task of finding suitable alternatives. While many high tenacity polyester fibers can be readily replaced, the Akra Type 161 presents a unique challenge due to its distinct physical properties.

Read more- By Eric Shippee

- 08/26/21

- 0 Comments

Synthetic textile yarns are used in low to medium pressure hose applications up to 300 psi as reinforcement. Circular Knitting and Spiral Wrapping are often used to integrate the reinforcing yarn into the garden hose, air hose, agricultural hose, industrial hose, automotive hose, etc. This article discusses these two methods and some tips that can improve processing for hose manufacturers using cone wound yarn for hose reinforcement.

Read more- By Service Thread

- 04/07/21

- 0 Comments

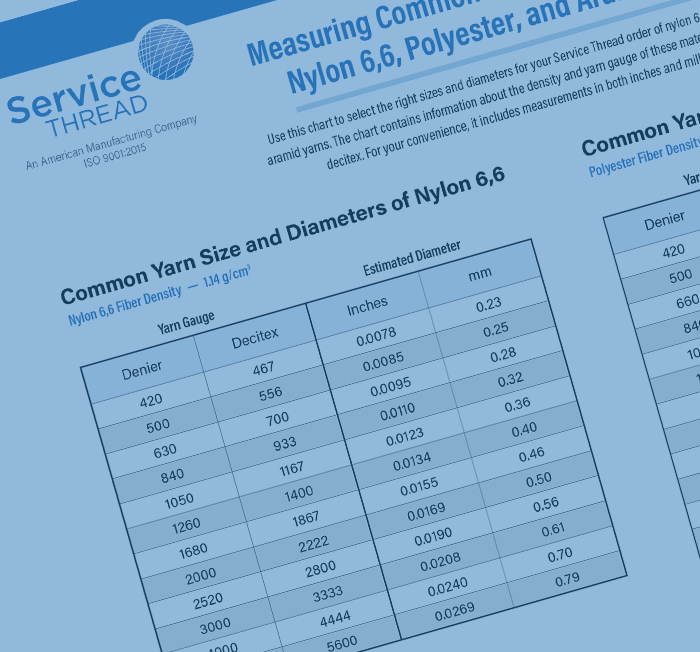

Because continuous multifilament polyester yarns are used in a wide variety of applications and conditions, polyester yarn manufacturers are required to have diverse product portfolios to accommodate them, including yarns in a wide denier range with various physical properties.

Read more- By Saurer, Guest Contributor

- 03/03/21

- 0 Comments

As an industrial thread supplier committed to developing smart, adaptive solutions, we discovered that we needed a versatile twister that could adapt to the requests of our clients across an incredibly vast array of industries.

Read more- By Eric Shippee

- 09/28/20

- 0 Comments

- By Dane Hatcher

- 04/15/20

- 0 Comments

When industrial sewing operations require high thread or yarn tensions, properly designed sewing threads and yarns are critical to continuous production flow. Bonded sewing thread and yarn tends to perform well for critical and challenging sewing conditions often faced by manufacturing companies. We’d like to provide some insight into how bonded thread affects tension in industrial sewing and manufacturing.

Read more- By Service Thread

- 01/03/20

- 0 Comments

Are you using the most modern and advanced yarn and thread? If you haven’t re-evaluated your options lately, it’s a good time to compare the latest yarn and thread materials to see if there is a better choice.

Read morePFAS-Free Non-Wicking Yarn Treatments: A Safer Alternative for High-Performance Textiles

- By Steve Zande

- 06/27/25

- Wire and Cable, Wicking Test, Waterblocking, Industrial Yarn, Polyester

- 0 Comments

As the textile industry faces rising scrutiny over chemical safety and environmental impact, one group of substances has come under particular fire: PFAS. Long valued for their ability to impart water- and stain-resistant properties, these “forever chemicals” are now being phased out across global markets. For manufacturers of high-performance yarns, this raises a critical challenge: how to maintain non-wicking functionality without PFAS.

Read moreOlder Posts

Navigating Tariffs: A Domestic Solution for Textile Manufacturers

- By Steve Zande

- 04/23/25

- 0 Comments

Recent developments in U.S. trade policy have once again put a spotlight on the vulnerability of supply chains that rely heavily on imported materials—particularly from China. With proposed tariff hikes targeting a wide range of goods, including industrial textiles and raw materials, manufacturers are facing increased pressure to find reliable, cost-effective alternatives closer to home.

Read moreBreak Strength, Elongation, and Shrinkage in Polyester for Industrial Markets

- By Steve Zande

- 12/13/24

- 0 Comments

Polyester yarns are fundamental to the performance and longevity of a wide range of industrial products. From hose reinforcement to binder yarns for fiber optic cables, tire cords, and industrial fabrics, the success of these applications hinges on achieving the right balance of mechanical properties. Among these critical properties, break strength, elongation, and shrinkage play pivotal roles. Each property serves a distinct purpose, and optimizing one can have a cascading effect on the others.

Read moreExploring Alternatives to Akra 161 Polyester: Navigating a Changing Landscape

- By Steve Zande

- 09/05/23

- 0 Comments

The recent news of Alfa Group's decision to close its filament polyester production plant in Mexico has sent shockwaves throughout the industry. Companies that once relied on Akra's products are now faced with the daunting task of finding suitable alternatives. While many high tenacity polyester fibers can be readily replaced, the Akra Type 161 presents a unique challenge due to its distinct physical properties.

Read moreTips to Improve Processing Efficiency of Textile Hose Reinforcement

- By Eric Shippee

- 08/26/21

- 0 Comments

Synthetic textile yarns are used in low to medium pressure hose applications up to 300 psi as reinforcement. Circular Knitting and Spiral Wrapping are often used to integrate the reinforcing yarn into the garden hose, air hose, agricultural hose, industrial hose, automotive hose, etc. This article discusses these two methods and some tips that can improve processing for hose manufacturers using cone wound yarn for hose reinforcement.

Read moreBecause continuous multifilament polyester yarns are used in a wide variety of applications and conditions, polyester yarn manufacturers are required to have diverse product portfolios to accommodate them, including yarns in a wide denier range with various physical properties.

Read moreAs an industrial thread supplier committed to developing smart, adaptive solutions, we discovered that we needed a versatile twister that could adapt to the requests of our clients across an incredibly vast array of industries.

Read moreWhat Effect Does Bonded Thread Have On Tensions in a Sewing Application?

- By Dane Hatcher

- 04/15/20

- 0 Comments

When industrial sewing operations require high thread or yarn tensions, properly designed sewing threads and yarns are critical to continuous production flow. Bonded sewing thread and yarn tends to perform well for critical and challenging sewing conditions often faced by manufacturing companies. We’d like to provide some insight into how bonded thread affects tension in industrial sewing and manufacturing.

Read moreOverview of Advanced and Modern Materials for Yarn and Thread Construction

- By Service Thread

- 01/03/20

- 0 Comments

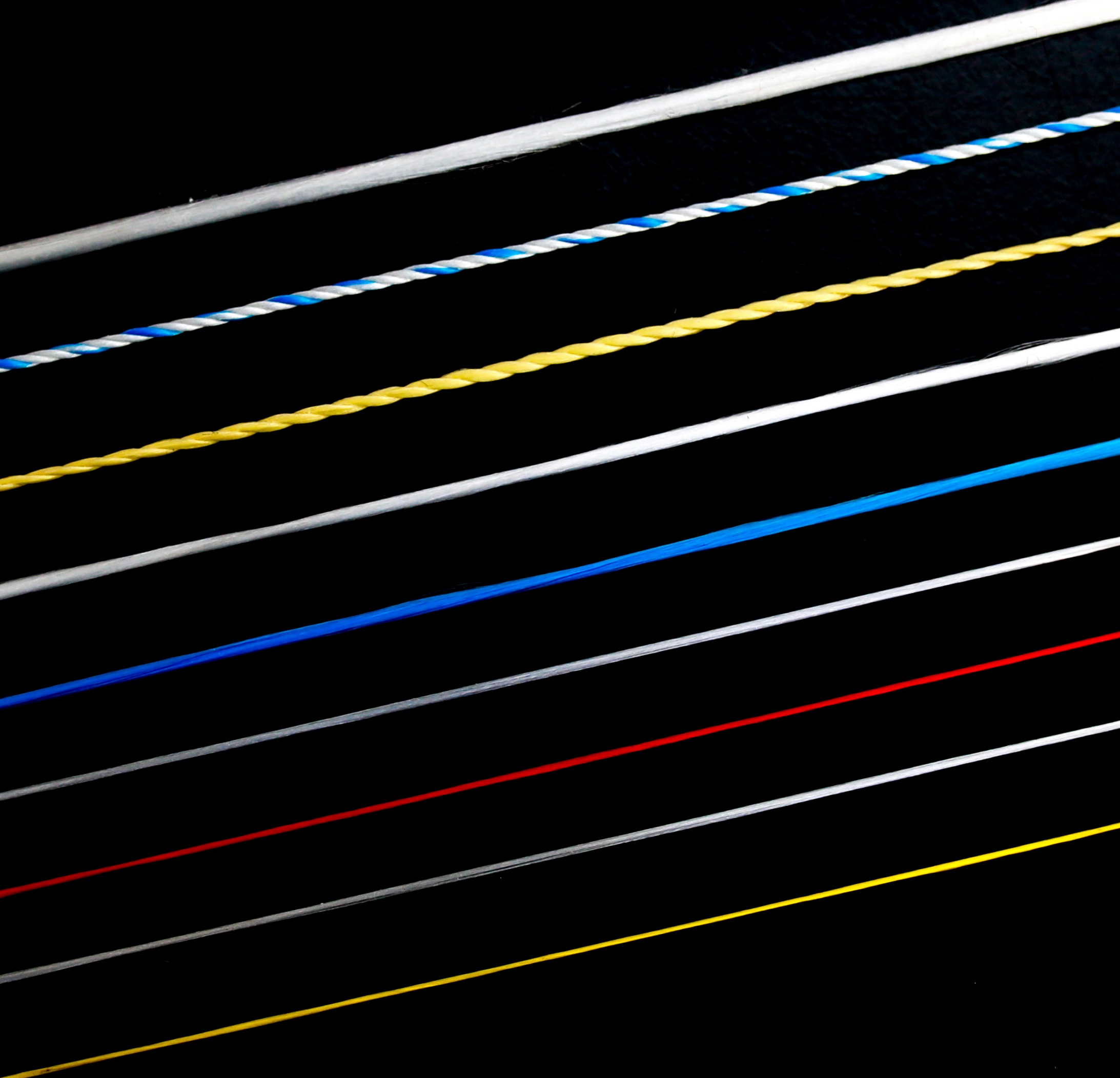

Are you using the most modern and advanced yarn and thread? If you haven’t re-evaluated your options lately, it’s a good time to compare the latest yarn and thread materials to see if there is a better choice.

Read more