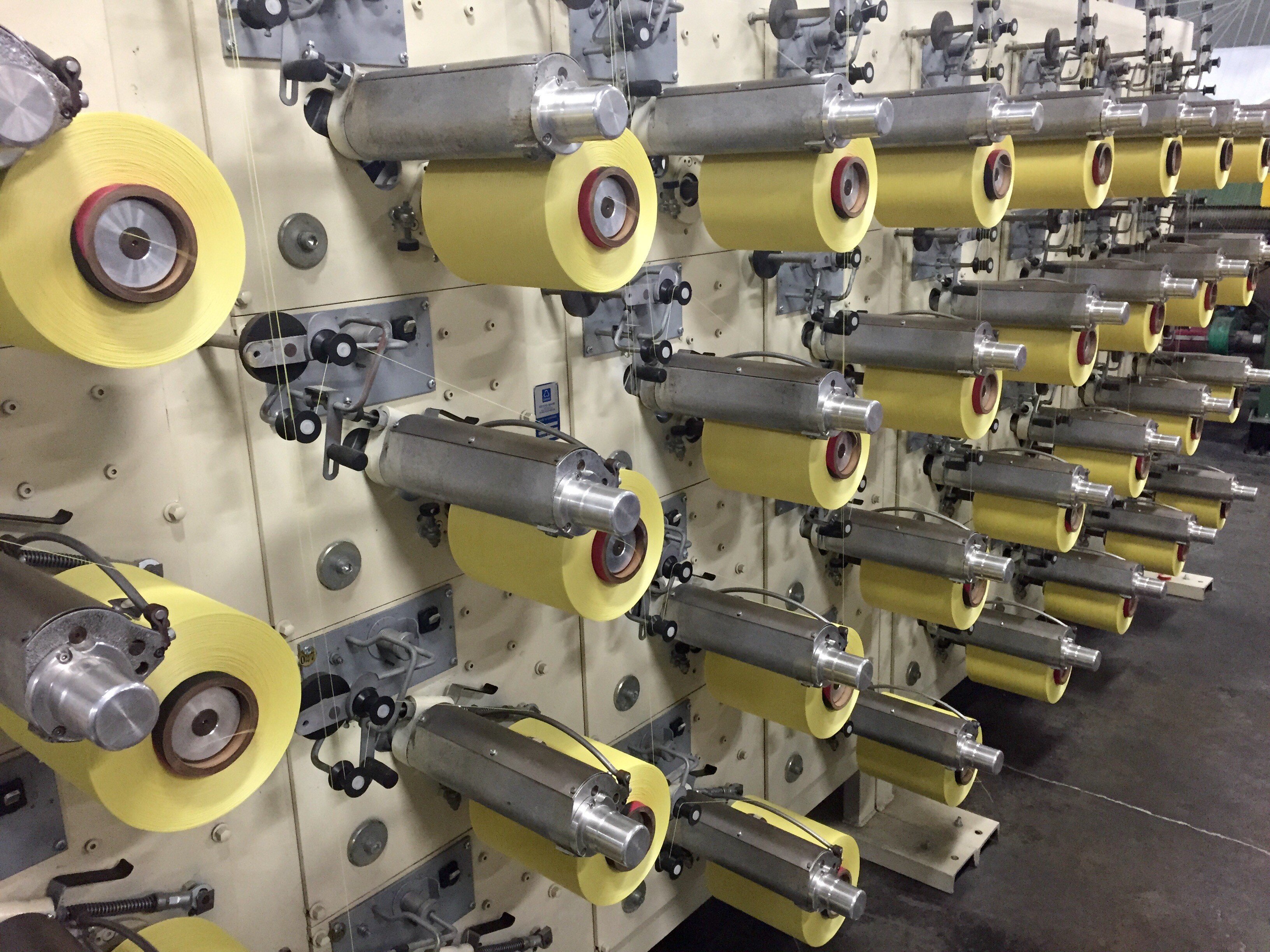

Synthetic textile yarns are used in low to medium pressure hose applications up to 300 psi as reinforcement. Circular Knitting and Spiral Wrapping are often used to integrate the reinforcing yarn into the garden hose, air hose, agricultural hose, industrial hose, automotive hose, etc. This article discusses these two methods and some tips that can improve processing for hose manufacturers using cone wound yarn for hose reinforcement.

Read morePosts by Eric Shippee

Tips to Improve Processing Efficiency of Textile Hose Reinforcement

- By Eric Shippee

- 08/26/21

- Industrial Yarn, Hose Reinforcement

- 0 Comments

- By Eric Shippee

- 09/28/20

- 0 Comments

- By Eric Shippee

- 05/07/20

- 0 Comments

Anyone who works with industrial fabrics knows DuPont™ Kevlar® has a reputation for being one of the world’s toughest fabrics. However, it’s sometimes criticized for being impossible to dye. This isn’t completely true.

Read more- By Eric Shippee

- 08/27/19

- 0 Comments

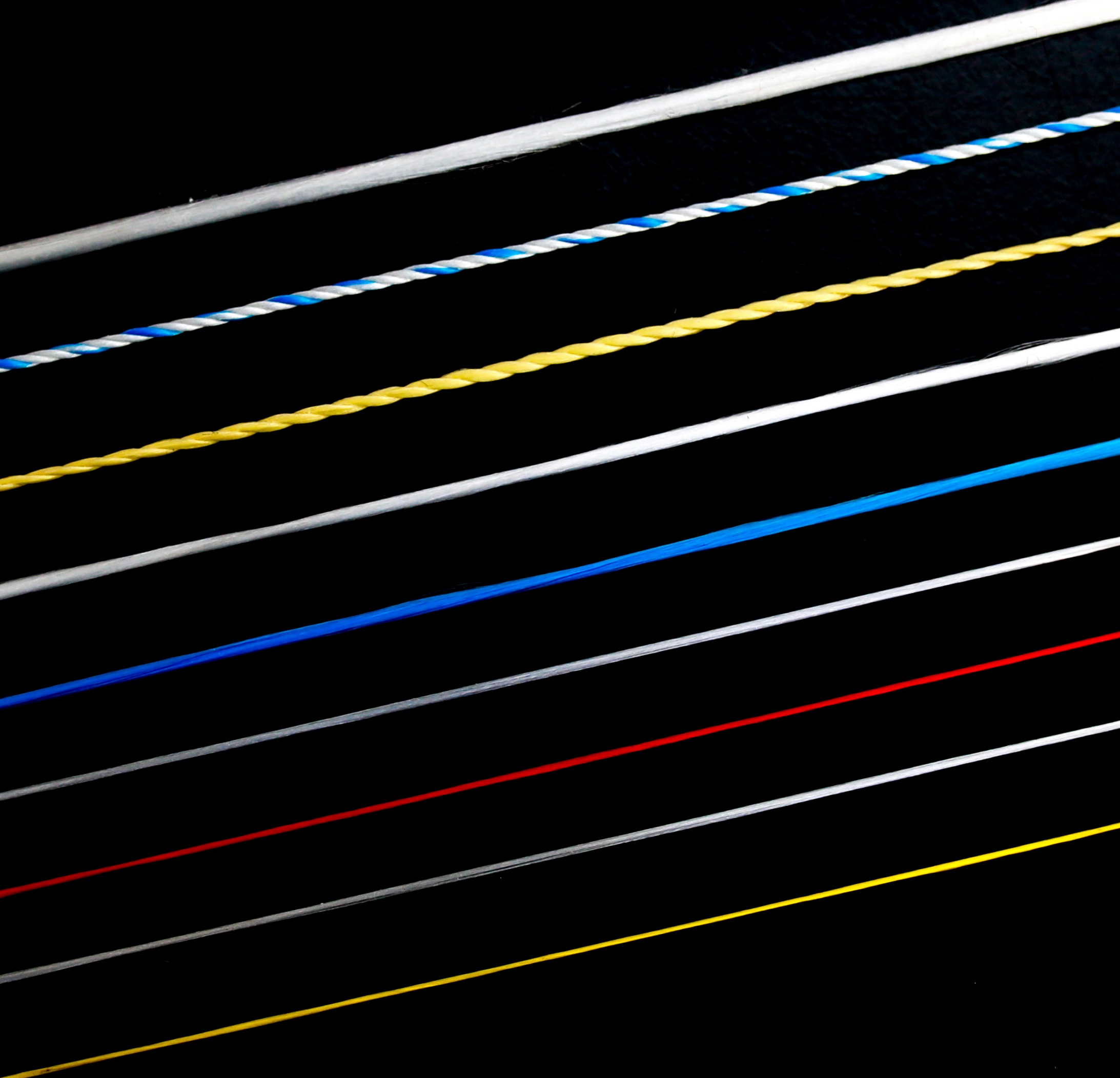

Meta-aramid and para-aramid fibers may be similar, but they have some significant differences. To better understand these differences, let’s look at the physical properties of each of these and see how they compare to a commodity high tenacity polyester.

Read more- By Eric Shippee

- 07/23/19

- 0 Comments

Industrial yarns and threads are made of various fiber types and sizes which aresupplied on a wide range of package sizes with different lengths and yields. Most products are ordered by the pound, which may leave you wondering, “How long is it?” It’s important to understand the length and yield of your products to help improve your processing efficiency and waste reduction.

Read more- By Eric Shippee

- 03/07/19

- 0 Comments

Tough and durable, UHMWPE (ultra-high-molecular-weight polyethylene) yarns have the highest tensile strength of any thermoplastic. You may also know these yarns by the names Spectra® and Dyneema®.

Read more- By Eric Shippee

- 07/10/18

- 2 Comments

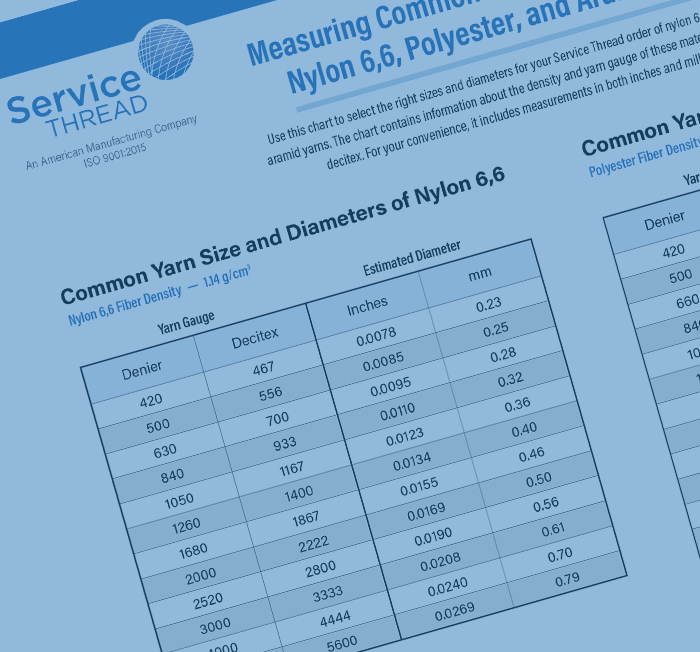

Recently, we have posted several blogs on determining yarn and thread size and the importance diameter has in specific manufacturing applications. Figuring out the diameter and size product that is needed can be calculated using the equations and conversion charts we have previously provided however, for quick reference we have also put together a list of the common industrial yarn types, sizes and diameters already converted for you!

Read more- By Eric Shippee

- 05/25/18

- 0 Comments

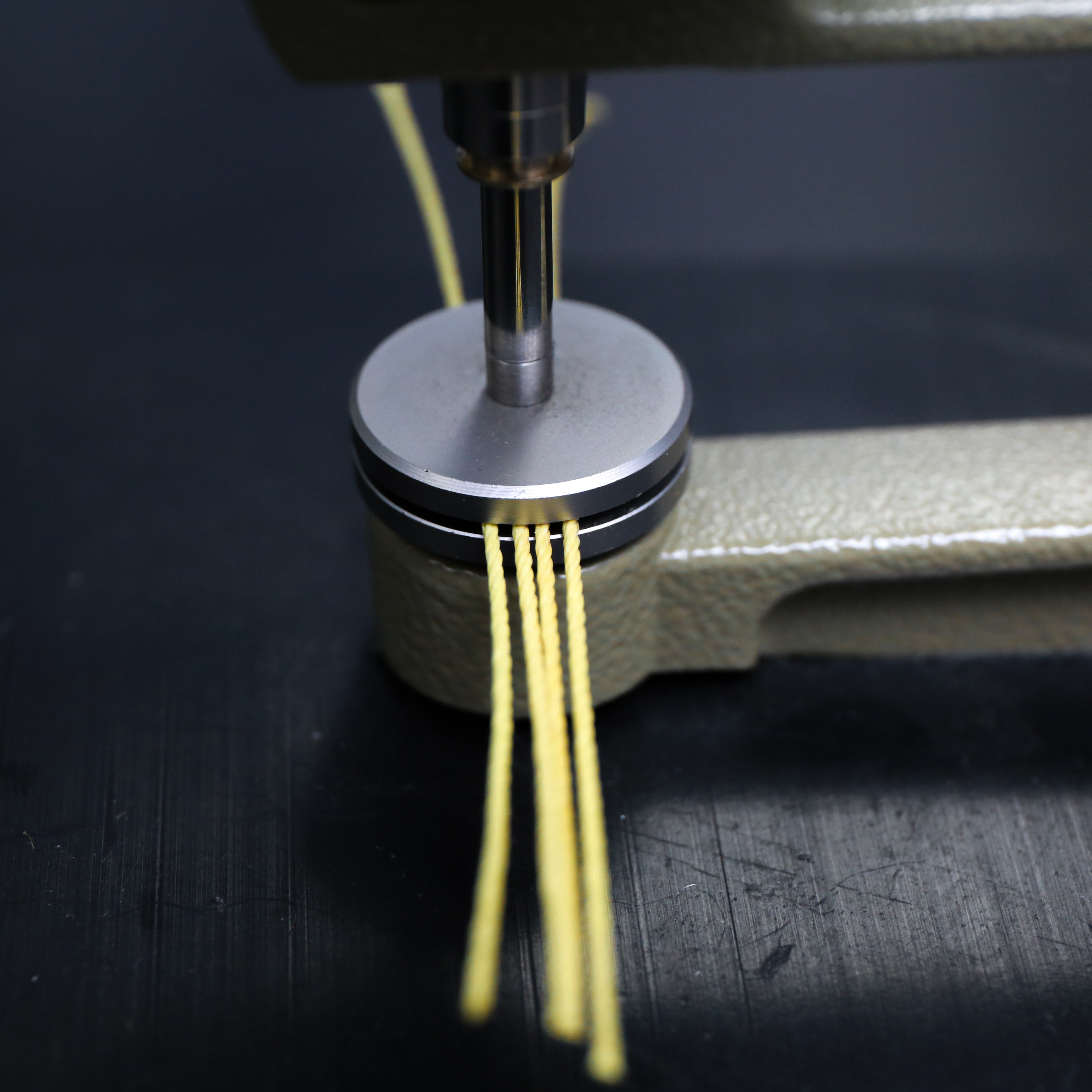

The relationship between yarn diameter and yarn size can be critical in determining the final product and fiber needed to meet specific application requirements. A yarn or thread size and its diameter will affect the coverage of a yarn in a hose, how large of a yarn will fit into a wire or cable, and is important in determining the needle size required in industrial sewing applications.

Read more- By Eric Shippee

- 05/15/18

- 1 Comment

Thickness (or diameter) is one of the basic physical properties of textile materials. In certain industrial applications, the thickness may require rigid control within specified limits. Bulk and warmth properties of textile materials are often estimated from their thickness values, and thickness is also useful in measuring some performance characteristics, such as before and after abrasion and shrinkage.

Eric Shippee

Recent Posts

Tips to Improve Processing Efficiency of Textile Hose Reinforcement

- By Eric Shippee

- 08/26/21

- Industrial Yarn, Hose Reinforcement

- 0 Comments

Synthetic textile yarns are used in low to medium pressure hose applications up to 300 psi as reinforcement. Circular Knitting and Spiral Wrapping are often used to integrate the reinforcing yarn into the garden hose, air hose, agricultural hose, industrial hose, automotive hose, etc. This article discusses these two methods and some tips that can improve processing for hose manufacturers using cone wound yarn for hose reinforcement.

Read moreOlder Posts

Can Kevlar® Be Dyed?

- By Eric Shippee

- 05/07/20

- 0 Comments

Anyone who works with industrial fabrics knows DuPont™ Kevlar® has a reputation for being one of the world’s toughest fabrics. However, it’s sometimes criticized for being impossible to dye. This isn’t completely true.

Read moreMeta-aramid and para-aramid fibers may be similar, but they have some significant differences. To better understand these differences, let’s look at the physical properties of each of these and see how they compare to a commodity high tenacity polyester.

Read moreIndustrial yarns and threads are made of various fiber types and sizes which aresupplied on a wide range of package sizes with different lengths and yields. Most products are ordered by the pound, which may leave you wondering, “How long is it?” It’s important to understand the length and yield of your products to help improve your processing efficiency and waste reduction.

Read moreUHMWPE Suppliers and Types

- By Eric Shippee

- 03/07/19

- 0 Comments

Tough and durable, UHMWPE (ultra-high-molecular-weight polyethylene) yarns have the highest tensile strength of any thermoplastic. You may also know these yarns by the names Spectra® and Dyneema®.

Read moreRecently, we have posted several blogs on determining yarn and thread size and the importance diameter has in specific manufacturing applications. Figuring out the diameter and size product that is needed can be calculated using the equations and conversion charts we have previously provided however, for quick reference we have also put together a list of the common industrial yarn types, sizes and diameters already converted for you!

Read moreThe relationship between yarn diameter and yarn size can be critical in determining the final product and fiber needed to meet specific application requirements. A yarn or thread size and its diameter will affect the coverage of a yarn in a hose, how large of a yarn will fit into a wire or cable, and is important in determining the needle size required in industrial sewing applications.

Read moreHow to Determine the Diameter (Thickness) and Width of Yarn or Thread

- By Eric Shippee

- 05/15/18

- 1 Comment

Thickness (or diameter) is one of the basic physical properties of textile materials. In certain industrial applications, the thickness may require rigid control within specified limits. Bulk and warmth properties of textile materials are often estimated from their thickness values, and thickness is also useful in measuring some performance characteristics, such as before and after abrasion and shrinkage.