The recent news of Alfa Group's decision to close its filament polyester production plant in Mexico has sent shockwaves throughout the industry. Companies that once relied on Akra's products are now faced with the daunting task of finding suitable alternatives. While many high tenacity polyester fibers can be readily replaced, the Akra Type 161 presents a unique challenge due to its distinct physical properties.

Read more- By Eric Shippee

- 08/26/21

- 0 Comments

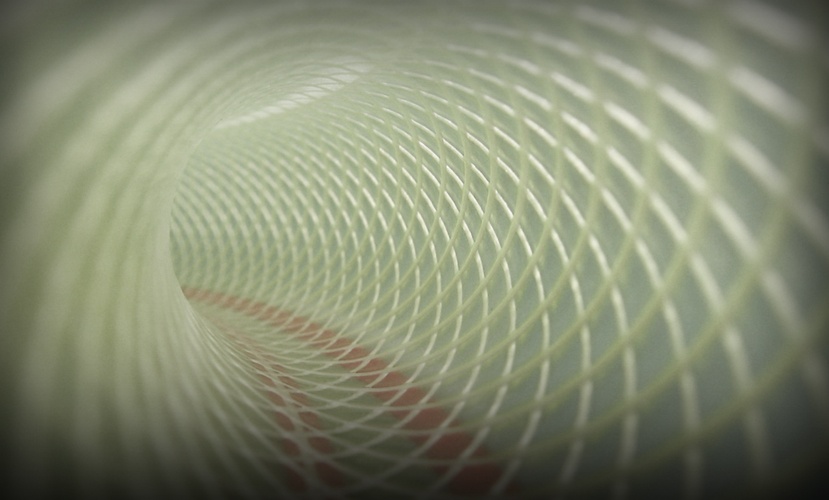

Synthetic textile yarns are used in low to medium pressure hose applications up to 300 psi as reinforcement. Circular Knitting and Spiral Wrapping are often used to integrate the reinforcing yarn into the garden hose, air hose, agricultural hose, industrial hose, automotive hose, etc. This article discusses these two methods and some tips that can improve processing for hose manufacturers using cone wound yarn for hose reinforcement.

Read more- By Steve Zande

- 07/27/18

- 0 Comments

When you are searching for a fiber or yarn for specific application requirements, there are many options to choose from. Meta-aramid and para-aramid yarns and threads are two popular choices for heat resistance and superior tensile strength.

Read more- By Steve Zande

- 03/20/18

- 0 Comments

Aramid fiber is best known by the trademark name DuPont™ Kevlar® and offers many unique and beneficial properties. With aramid raw material costs between five and thirty times the cost of nylon or polyester, many manufacturers look for ways to save when aramids are required for their application. What seems on the surface like an easy question is a lot more complicated than you might think. So, what are some of the factors that contribute to the total cost of industrial aramid yarn or thread?

Read more- By Eric Shippee

- 01/26/18

- 0 Comments

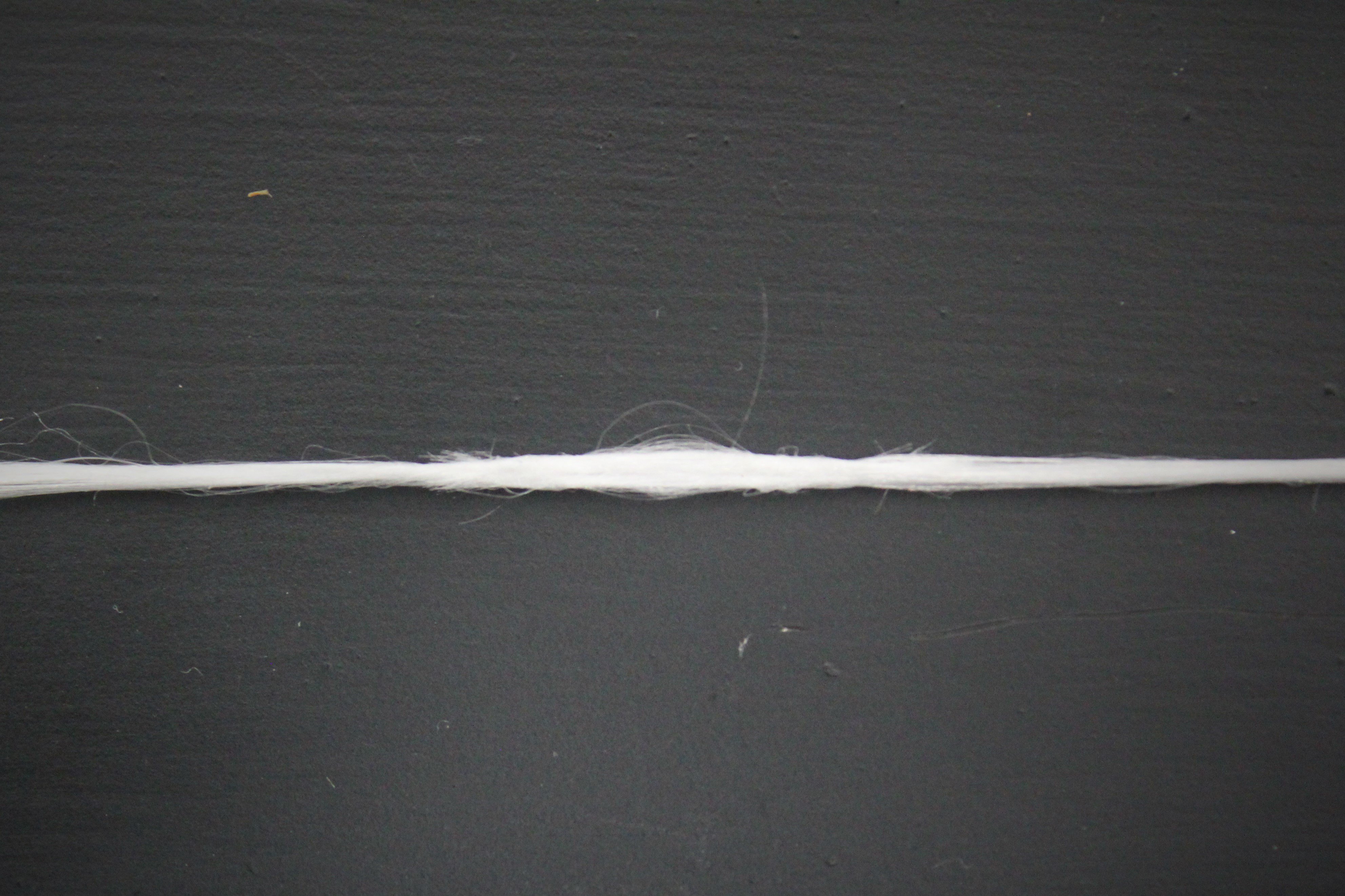

The practice of joining industrial yarn ends (resulting from breaks, defects, or end of the supply), is a critical component to the product manufacturing process, particularly in industries such as wire and cable (integration of ripcords), hose reinforcement, belting and more. When using industrial yarn in the production process, it is essential that the joining method endures the process without interruption and does not have a negative effect on the quality of the end product.

Read more- By Eric Shippee

- 10/27/17

- 0 Comments

Both Vectran™ and Aramid yarns are known for being resilient materials used for specialized products. They each have varying degrees of creep resistance, abrasion resistance, high tensile strength, excellent flex/fold characteristics, long term dimensional stability and exceptional property retention at high temperatures. These yarns are extremely durable and often used to protect people and products.

Read more- By Steve Zande

- 09/26/17

- 2 Comments

Vectran™ is a manufactured fiber used to make specialty fabric and typically only those with a specific product application know much about it. This multifilament yarn is spun from a liquid crystal polymer (LCP) and is the only commercially available melt-spun LCP fiber in the world. Vectran™ fiber presents exceptional strength and rigidity because the material is five times stronger than steel and ten times stronger than aluminum. There are no real alternatives when it comes to working with Vectran™ as the qualities it brings to the table are distinctive and highly beneficial.

Read more- By Torry Losch

- 06/13/17

- 2 Comments

In part one of Service Thread’s blog series on polyester yarn pricing, I discussed the reason for the unpredictable cost swings with polyester yarn pricing. In addition to understanding the global dynamics that effect these swings, it is also important to understand the pricing strategies used.

Read more- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read more- By Eric Shippee

- 01/20/17

- 0 Comments

Over the past 20 years, more than 100 major sports facilities have opened in the United States to join the thousands already in operation. Throughout these sports complexes, concession stands see a great amount of traffic as fans enjoy stadium food and beverages during events. In particular, beverage hoses are a critical element in the sanitary dispensing of soda, beer and more.

Read moreThe recent news of Alfa Group's decision to close its filament polyester production plant in Mexico has sent shockwaves throughout the industry. Companies that once relied on Akra's products are now faced with the daunting task of finding suitable alternatives. While many high tenacity polyester fibers can be readily replaced, the Akra Type 161 presents a unique challenge due to its distinct physical properties.

Read moreOlder Posts

Tips to Improve Processing Efficiency of Textile Hose Reinforcement

- By Eric Shippee

- 08/26/21

- 0 Comments

Synthetic textile yarns are used in low to medium pressure hose applications up to 300 psi as reinforcement. Circular Knitting and Spiral Wrapping are often used to integrate the reinforcing yarn into the garden hose, air hose, agricultural hose, industrial hose, automotive hose, etc. This article discusses these two methods and some tips that can improve processing for hose manufacturers using cone wound yarn for hose reinforcement.

Read moreWhen you are searching for a fiber or yarn for specific application requirements, there are many options to choose from. Meta-aramid and para-aramid yarns and threads are two popular choices for heat resistance and superior tensile strength.

Read moreAramid fiber is best known by the trademark name DuPont™ Kevlar® and offers many unique and beneficial properties. With aramid raw material costs between five and thirty times the cost of nylon or polyester, many manufacturers look for ways to save when aramids are required for their application. What seems on the surface like an easy question is a lot more complicated than you might think. So, what are some of the factors that contribute to the total cost of industrial aramid yarn or thread?

Read moreThe practice of joining industrial yarn ends (resulting from breaks, defects, or end of the supply), is a critical component to the product manufacturing process, particularly in industries such as wire and cable (integration of ripcords), hose reinforcement, belting and more. When using industrial yarn in the production process, it is essential that the joining method endures the process without interruption and does not have a negative effect on the quality of the end product.

Read moreVectran™ Vs. Aramid

- By Eric Shippee

- 10/27/17

- 0 Comments

Both Vectran™ and Aramid yarns are known for being resilient materials used for specialized products. They each have varying degrees of creep resistance, abrasion resistance, high tensile strength, excellent flex/fold characteristics, long term dimensional stability and exceptional property retention at high temperatures. These yarns are extremely durable and often used to protect people and products.

Read moreWhat is Vectran™?

- By Steve Zande

- 09/26/17

- 2 Comments

Vectran™ is a manufactured fiber used to make specialty fabric and typically only those with a specific product application know much about it. This multifilament yarn is spun from a liquid crystal polymer (LCP) and is the only commercially available melt-spun LCP fiber in the world. Vectran™ fiber presents exceptional strength and rigidity because the material is five times stronger than steel and ten times stronger than aluminum. There are no real alternatives when it comes to working with Vectran™ as the qualities it brings to the table are distinctive and highly beneficial.

Read morePolyester Yarn Price Update Part Two: Understanding Market, Spot and Indexed Pricing

- By Torry Losch

- 06/13/17

- 2 Comments

In part one of Service Thread’s blog series on polyester yarn pricing, I discussed the reason for the unpredictable cost swings with polyester yarn pricing. In addition to understanding the global dynamics that effect these swings, it is also important to understand the pricing strategies used.

Read moreWhat is ASTM D4974? Hot Air Shrinkage Test for Yarn & Cord Explained

- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read more5 Reasons to Use Industrial Yarn as Reinforcement in Beverage Hoses

- By Eric Shippee

- 01/20/17

- 0 Comments

Over the past 20 years, more than 100 major sports facilities have opened in the United States to join the thousands already in operation. Throughout these sports complexes, concession stands see a great amount of traffic as fans enjoy stadium food and beverages during events. In particular, beverage hoses are a critical element in the sanitary dispensing of soda, beer and more.

Read more