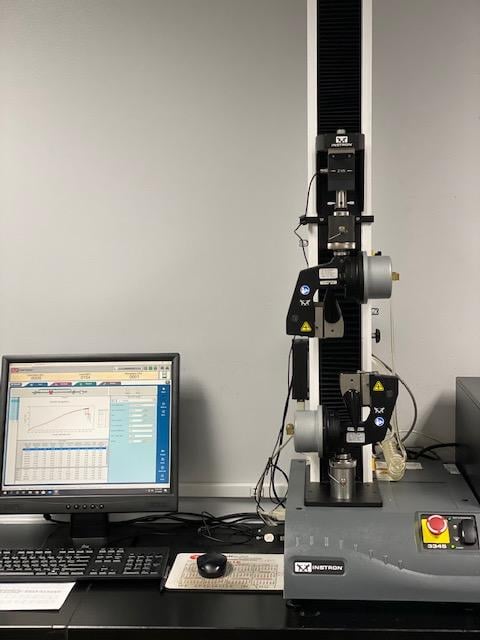

Knowing the tensile strength of industrial yarn and thread is essential to maintaining the productivity of production environments. By pinpointing the tensile strength, you can operate within safe bounds to prevent breaks that halt production and hamper efficiency.

Read more- By Eric Shippee

- 01/19/18

- 0 Comments

Industrial yarn is designed and engineered to be incorporated into products where oftentimes, a functional requirement supersedes aesthetic considerations. Used by non-apparel industry product manufacturers, industrial yarns are typically a component part of a product to enhance the strength, durability, performance and other high-value properties of the product.

Industrial yarn is designed and engineered to be incorporated into products where oftentimes, a functional requirement supersedes aesthetic considerations. Used by non-apparel industry product manufacturers, industrial yarns are typically a component part of a product to enhance the strength, durability, performance and other high-value properties of the product.

- By Eric Shippee

- 12/22/17

- 0 Comments

- By Eric Shippee

- 09/07/17

- 0 Comments

When yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

Read more- By Eric Shippee

- 07/19/17

- 1 Comment

- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read more- By Eric Shippee

- 10/25/16

- 0 Comments

Manufacturers of wire and cable understand the importance of preventing moisture from making contact with fiber optics. Conducting a water wicking test for yarn and thread used in the manufacturing process can help with product evaluation, as well as save time and money in the long term.

Read more- By Steve Zande

- 12/04/15

- 0 Comments

Many products use components created in places other than the final assembly site. Each component must itself conform to safety standards. The logic here is that if something is composed of parts that each pass safety tests, the final product will be safety compliant. A mattress is such a product, and its materials must be fire resistant so that the product sold to consumers can be deemed safe.

Read moreKnowing the tensile strength of industrial yarn and thread is essential to maintaining the productivity of production environments. By pinpointing the tensile strength, you can operate within safe bounds to prevent breaks that halt production and hamper efficiency.

Read moreOlder Posts

Industrial yarn is designed and engineered to be incorporated into products where oftentimes, a functional requirement supersedes aesthetic considerations. Used by non-apparel industry product manufacturers, industrial yarns are typically a component part of a product to enhance the strength, durability, performance and other high-value properties of the product.

Industrial yarn is designed and engineered to be incorporated into products where oftentimes, a functional requirement supersedes aesthetic considerations. Used by non-apparel industry product manufacturers, industrial yarns are typically a component part of a product to enhance the strength, durability, performance and other high-value properties of the product.

When yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

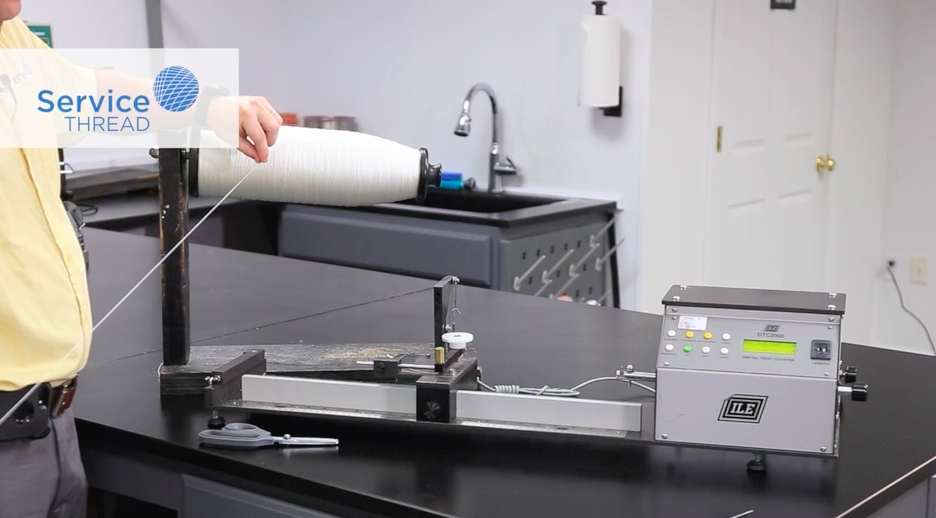

Read moreWhat is ASTM D4974? Hot Air Shrinkage Test for Yarn & Cord Explained

- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

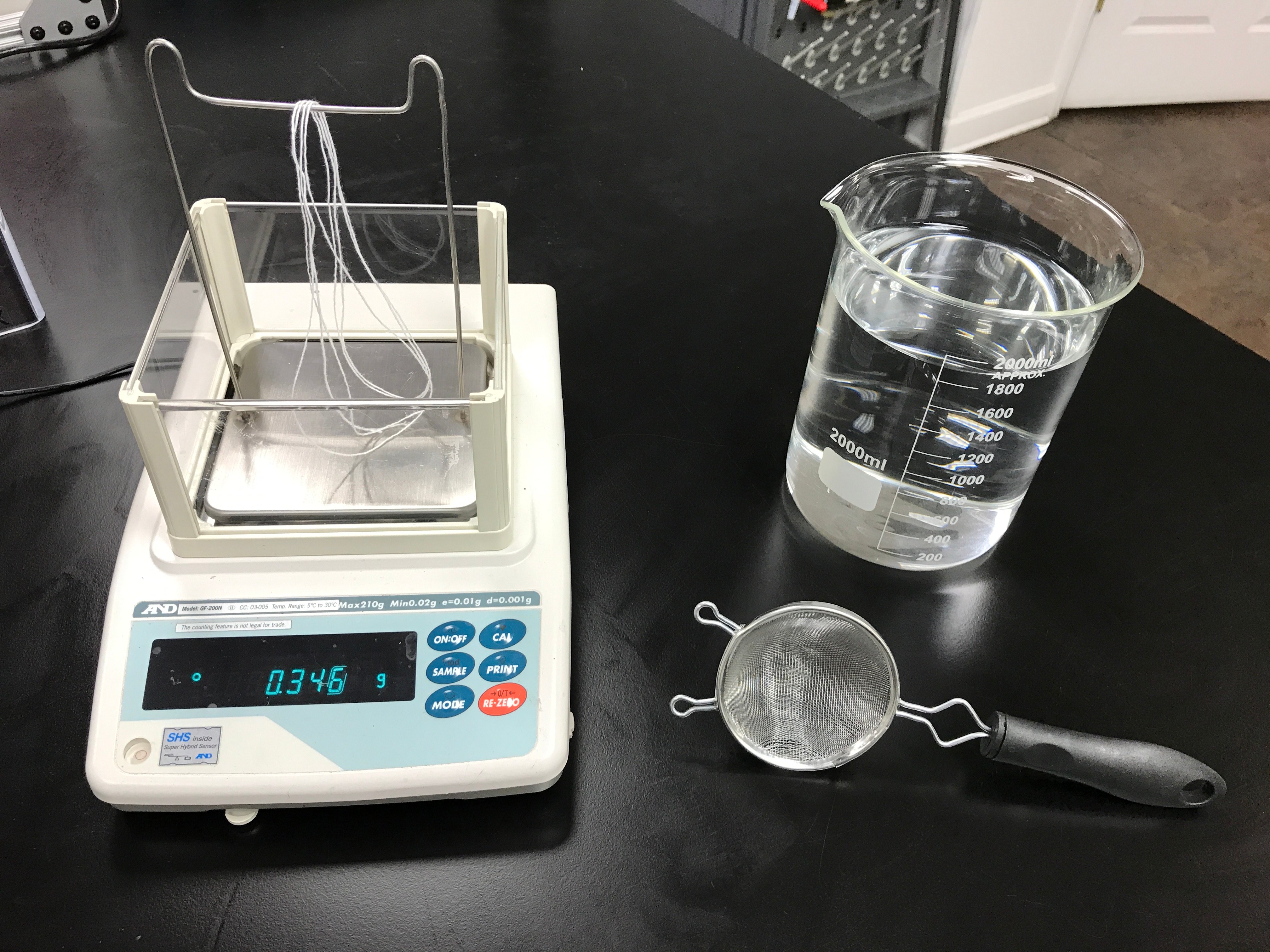

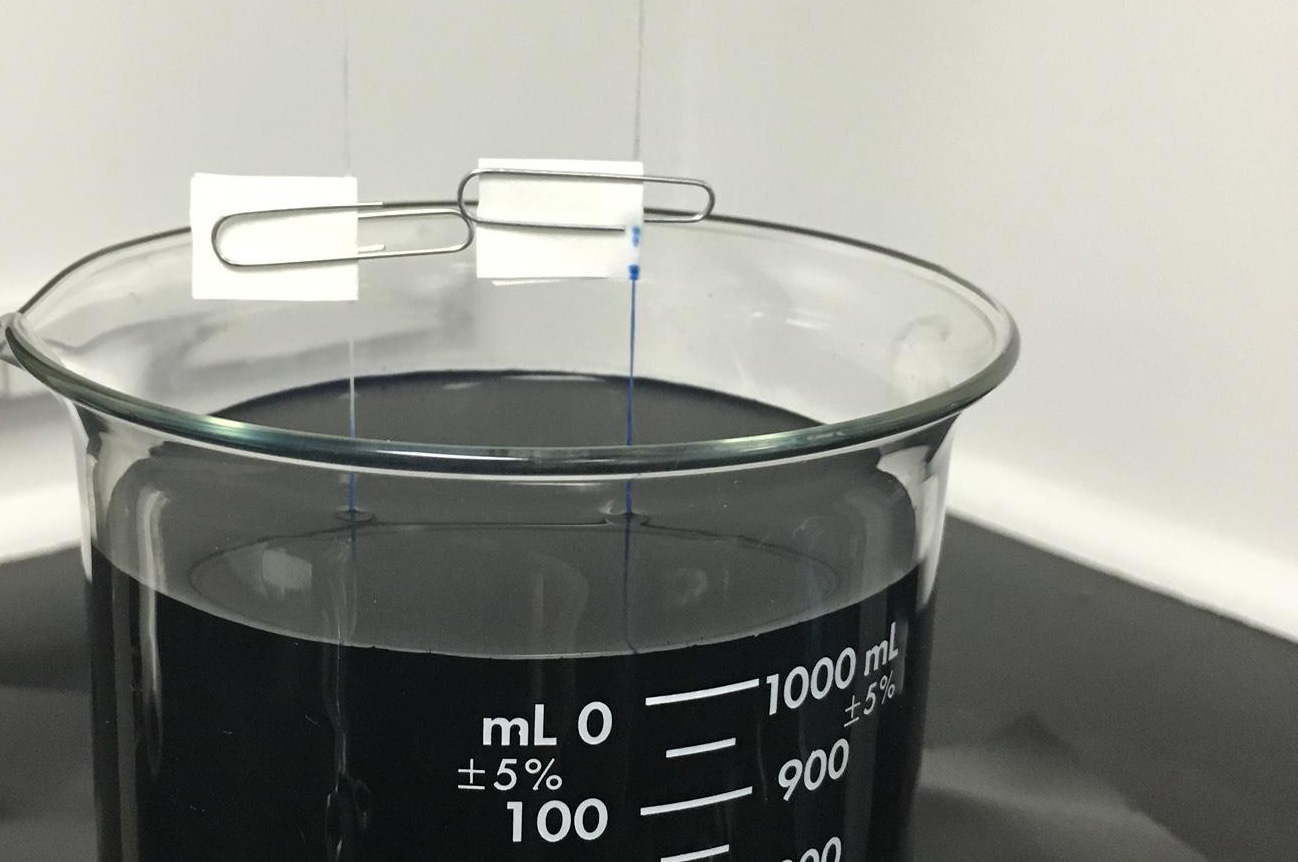

Read moreHow to Test Non-Wicking Properties of Yarns and Fibers for Wire and Cable

- By Eric Shippee

- 10/25/16

- 0 Comments

Manufacturers of wire and cable understand the importance of preventing moisture from making contact with fiber optics. Conducting a water wicking test for yarn and thread used in the manufacturing process can help with product evaluation, as well as save time and money in the long term.

Read moreASTM D7016 - Importance of fire retardant sewing thread in mattresses

- By Steve Zande

- 12/04/15

- 0 Comments

Many products use components created in places other than the final assembly site. Each component must itself conform to safety standards. The logic here is that if something is composed of parts that each pass safety tests, the final product will be safety compliant. A mattress is such a product, and its materials must be fire resistant so that the product sold to consumers can be deemed safe.

Read more