Knowing the tensile strength of industrial yarn and thread is essential to  maintaining the productivity of production environments. By pinpointing the tensile strength, you can operate within safe bounds to prevent breaks that halt production and hamper efficiency.

maintaining the productivity of production environments. By pinpointing the tensile strength, you can operate within safe bounds to prevent breaks that halt production and hamper efficiency.

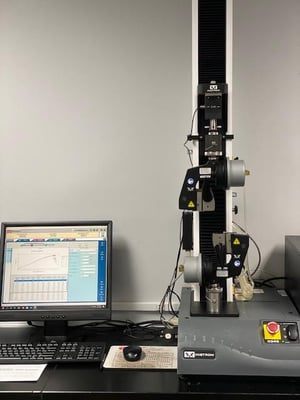

In order to conduct tensile testing for yarn and thread, you must use a specific type of clamp and the proper load cell. This is the only way to get completely accurate results. If you need to conduct tensile testing, read on to learn more.

What is a Testing Clamp?

A testing clamp is a specially-designed horn with a smooth, highly-polished, contoured surface and a graduated cam that allows for easy loading. It has a clamping mechanism that grips materials cleanly for an accurate test result every time.

The clamping mechanism can be activated either automatically or through a footswitch to allow hands-free operation. Pneumatic cord and yarn grips provide selectable clamping force to accommodate various materials.

Why is a Testing Clamp Needed?

A high-quality testing clamp is an asset to your production environment. It allows you to monitor tensile strengths constantly without slowing or stopping production.

Specialty testing clamps are a must because the gripping area is small for most monofilaments, cords, and yarns. This means normal techniques that use standard grip faces usually result in failures, which are time-consuming and costly.

The clamp’s pneumatic cord and yarn grips are designed specifically to overcome the problem of failure by incorporating a capstan design. A capstan evenly distributes the gripping force over the surface, meaning you get a smooth grip with no unnecessary friction or wear.

Like your industrial sewing environment, a testing clamp is under constant strain from the physical forces involved. That’s why you’ll need a high-quality testing clamp that supports fast, reliable testing and offers excellent movement to compensate for any decay of the holding force due to creep.

What Size Load Cell Should be Used for Testing?

The load cell converts the forces of tension into electrical signals that create data to measure, test, and monitor. As the force applied to the load cell increases, the electrical signal changes accordingly and provides a helpful readout.

Your load cell provides a high degree of accuracy and should be specific to the range of tensile strength where the minimum break is no less than 10% of the cell load capacity. So match your load cell to your breakpoints.

For example, fine-denier spun yarns that break at less than 10 pounds won’t be accurate using a high-capacity load cell that’s intended for aramid yarns that break at 100-plus pounds. Work with your tensile testing clamp/load cell vendor to ensure you’re selecting the right load cell for each individual range of tensile strength.

How Does Tensile Testing Work?

In your production environment, tensile testing occurs as the production line flows. The specimen is placed over the top of the horn and slides down to the proper gripping position on the contoured clamp.

You can open or close the grip using the pneumatic footswitch for hands-free operation. It’s easy to conduct the testing and monitor the results without slowing or stopping the normal level of production.

Conduct tensile testing for yarn and thread, compare your results to your company’s production standards, and make adjustments as necessary. When you use high-quality tensile testing equipment, it’s fast and easy to make nimble adjustments that keep your production facility running efficiently.

Comparing Tests From One Machine to Another

It’s always a good idea to compare your test results between machines and look for variation from one machine to another. What is the variation between load cells and specific clamps? What does this tell you about your materials and tensions?

For more help answering questions about your materials, tensile strengths, and production environment setup, contact the experts at Service Thread.

Together, Instron and Service Thread provide some of the highest-quality equipment used in tensile testing for yarn and thread available anywhere in the world.