When sewing, is your needle heating up and causing damage to your thread or material, compromising the strength of your seams?

Read more- By Dane Hatcher

- 05/11/21

- 0 Comments

Your Class 7 Style sewing machine is an asset to your operations; one that needs careful maintenance to keep it in proper working order.

Read more- By Dane Hatcher

- 03/12/21

- 0 Comments

If an industrial sewing machine operator is sewing with excessive tension, it can literally stretch the thread as it’s being sewn and weaken the seam, which compromises the integrity of the product that’s being sewn.

Read more- By Service Thread

- 07/08/20

- 0 Comments

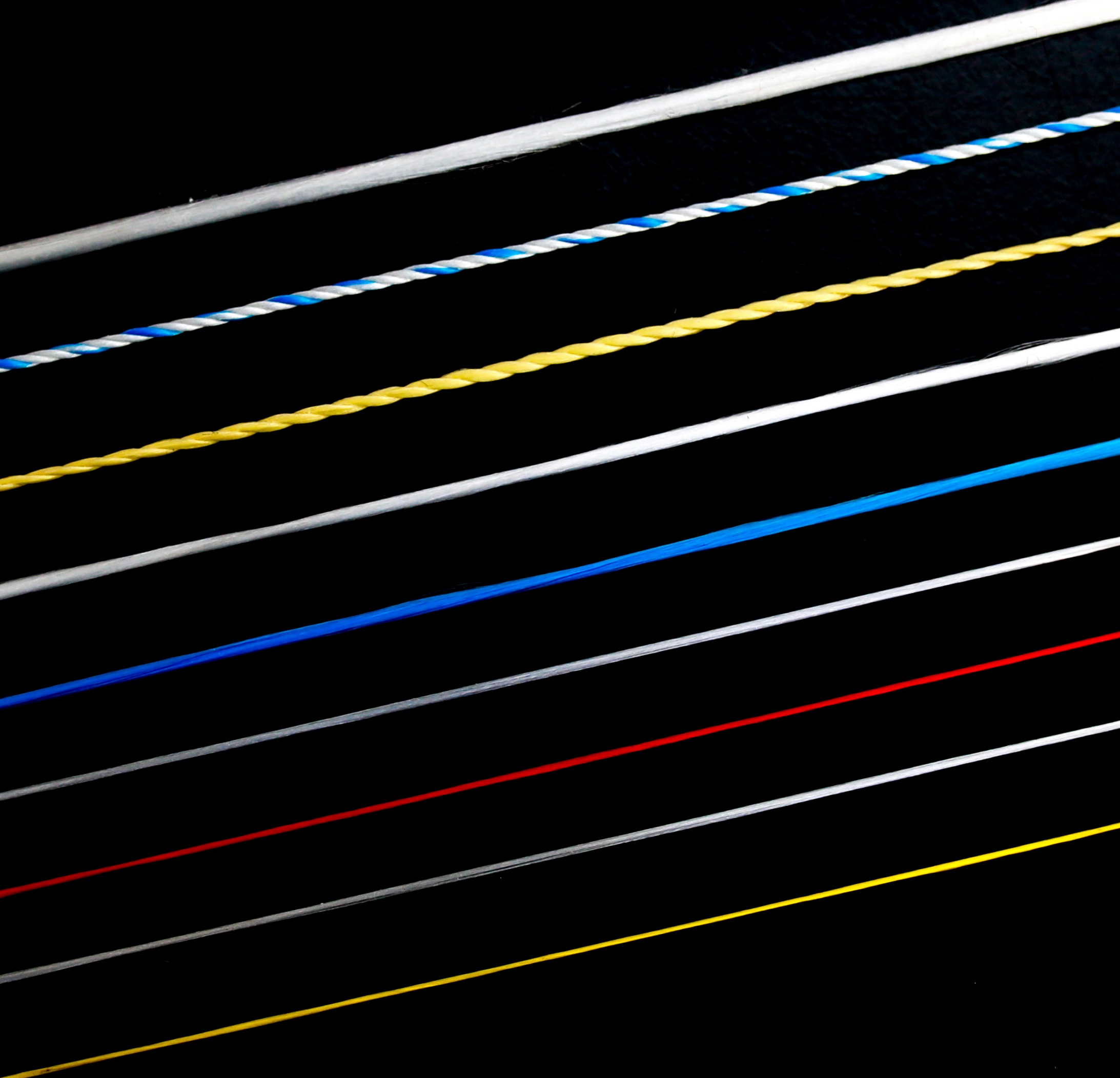

Industrial sewing thread is quite different from the thread that is typically used in garments and apparel. If you’re looking for household sewing thread, we’d like to direct you to Walmart, Michael’s, or another household thread supplier.

Not sure which is which? Here’s a look at the main differences between industrial sewing thread and household sewing thread, plus some tips on choosing the right thread for your application.

- By Service Thread

- 05/19/20

- 2 Comments

Bonded thread size is communicated in various ways, mainly by ticket number and tex size. Although it’s easy to get caught up in the lingo and confuse the two, the ticket number and tex size are distinct characteristics of a bonded thread.

Read more- By Dane Hatcher

- 04/15/20

- 0 Comments

When industrial sewing operations require high thread or yarn tensions, properly designed sewing threads and yarns are critical to continuous production flow. Bonded sewing thread and yarn tends to perform well for critical and challenging sewing conditions often faced by manufacturing companies. We’d like to provide some insight into how bonded thread affects tension in industrial sewing and manufacturing.

Read more- By Dane Hatcher

- 04/06/20

- 0 Comments

It’s important to evaluate whether you should be using a bonded or non-bonded thread in your industrial sewing process. For manufacturers, each type of industrial sewing thread or yarn has its own set of advantages and disadvantages, so let’s take a closer look at each option and which might be right for your application.

Read more- By Service Thread

- 03/23/20

- 0 Comments

When you’re sewing at high speeds, bonded thread prevents snags and breaks that cause production interruptions and create flaws in your products. In many applications, bonded sewing thread is almost always a superior choice.

Read more- By Service Thread

- 01/03/20

- 0 Comments

Are you using the most modern and advanced yarn and thread? If you haven’t re-evaluated your options lately, it’s a good time to compare the latest yarn and thread materials to see if there is a better choice.

Read more- By Service Thread

- 12/11/19

- 0 Comments

When sewing, is your needle heating up and causing damage to your thread or material, compromising the strength of your seams?

Read moreOlder Posts

Service Class 7 Troubleshooting Series: Cleaning a Class 7 Style Sewing Machine

- By Dane Hatcher

- 05/11/21

- 0 Comments

Your Class 7 Style sewing machine is an asset to your operations; one that needs careful maintenance to keep it in proper working order.

Read moreIf an industrial sewing machine operator is sewing with excessive tension, it can literally stretch the thread as it’s being sewn and weaken the seam, which compromises the integrity of the product that’s being sewn.

Read moreIndustrial sewing thread is quite different from the thread that is typically used in garments and apparel. If you’re looking for household sewing thread, we’d like to direct you to Walmart, Michael’s, or another household thread supplier.

Not sure which is which? Here’s a look at the main differences between industrial sewing thread and household sewing thread, plus some tips on choosing the right thread for your application.

What Is the Difference Between Ticket Size and Tex Size for Bonded Thread?

- By Service Thread

- 05/19/20

- 2 Comments

Bonded thread size is communicated in various ways, mainly by ticket number and tex size. Although it’s easy to get caught up in the lingo and confuse the two, the ticket number and tex size are distinct characteristics of a bonded thread.

Read moreWhat Effect Does Bonded Thread Have On Tensions in a Sewing Application?

- By Dane Hatcher

- 04/15/20

- 0 Comments

When industrial sewing operations require high thread or yarn tensions, properly designed sewing threads and yarns are critical to continuous production flow. Bonded sewing thread and yarn tends to perform well for critical and challenging sewing conditions often faced by manufacturing companies. We’d like to provide some insight into how bonded thread affects tension in industrial sewing and manufacturing.

Read moreIt’s important to evaluate whether you should be using a bonded or non-bonded thread in your industrial sewing process. For manufacturers, each type of industrial sewing thread or yarn has its own set of advantages and disadvantages, so let’s take a closer look at each option and which might be right for your application.

Read moreWhen you’re sewing at high speeds, bonded thread prevents snags and breaks that cause production interruptions and create flaws in your products. In many applications, bonded sewing thread is almost always a superior choice.

Read moreOverview of Advanced and Modern Materials for Yarn and Thread Construction

- By Service Thread

- 01/03/20

- 0 Comments

Are you using the most modern and advanced yarn and thread? If you haven’t re-evaluated your options lately, it’s a good time to compare the latest yarn and thread materials to see if there is a better choice.

Read more

.jpg)