The video above features NeC 8/4 staple spun polyester. The untreated thread on the left burns vigorously once ignition temperature is reached, melts, emits black smoke and drips. The treated thread on the right melts and drips, however, resists combustion and flaming, therefore, smoke is greatly reduced, retardant has done its job.

Read more- By Eric Shippee

- 07/23/19

- 0 Comments

Industrial yarns and threads are made of various fiber types and sizes which aresupplied on a wide range of package sizes with different lengths and yields. Most products are ordered by the pound, which may leave you wondering, “How long is it?” It’s important to understand the length and yield of your products to help improve your processing efficiency and waste reduction.

Read more- By Jay Todd

- 05/13/19

- 0 Comments

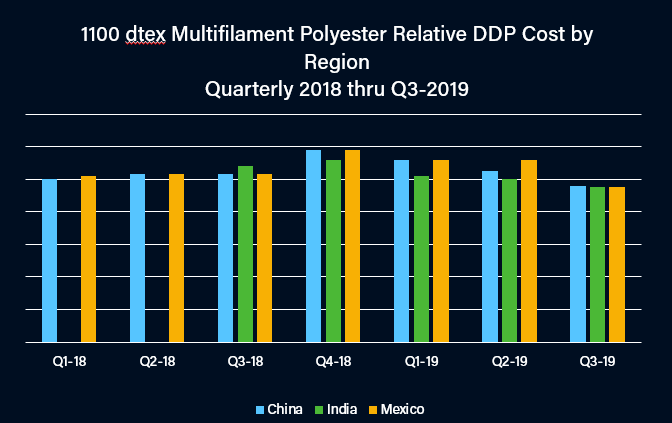

Unlike the September 2018 10 percent tariff, the additional 15 percent announced for shipments on or after May 10th may not have an immediate impact on the price of polyester yarn imports to the U.S.

Read more- By Steve Zande

- 03/14/19

- 1 Comment

If you’ve come across the term Cotton Count and were a bit confused, you’re not alone. The terminology of the yarn and thread industry can be tricky.

Read more- By Jay Todd

- 11/12/18

- 0 Comments

The Industrial Fabrics Foundation(IFF) has selected Service Thread for the 2018 Greater Good Award.

Read more- By Torry Losch

- 09/21/18

- 0 Comments

On September 17th the United States Trade Representative (USTR) Office announced additional tariffs of 10 percent on 5,745 items with an approximate value of $200 billion USD. As most of the world is aware, the Trump Administration and China are in a heated economic battle.

Read more- By Steve Zande

- 09/14/18

- 0 Comments

Typically Mil Spec sewing thread standards are long and divided into several sections. They define physical characteristics of thread and are a good reference point for manufacturers however, they can be confusing and its important to understand the basics. Here is a quick guide to the 8 page standard, A-A-55195 (formerly MIL-T-44100) spun para-aramid sewing threads.

Read more- By Eric Shippee

- 05/15/18

- 1 Comment

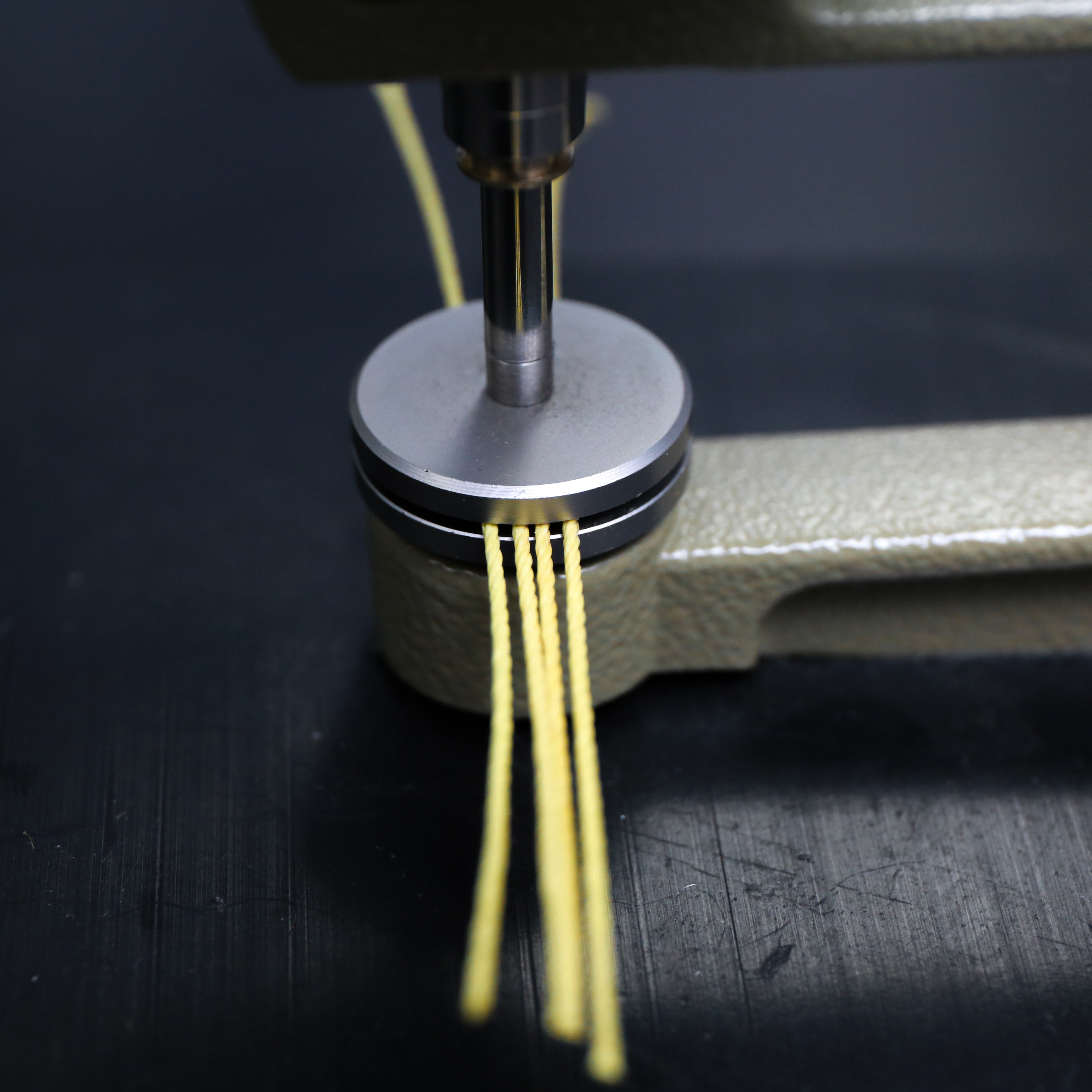

Thickness (or diameter) is one of the basic physical properties of textile materials. In certain industrial applications, the thickness may require rigid control within specified limits. Bulk and warmth properties of textile materials are often estimated from their thickness values, and thickness is also useful in measuring some performance characteristics, such as before and after abrasion and shrinkage.

The video above features NeC 8/4 staple spun polyester. The untreated thread on the left burns vigorously once ignition temperature is reached, melts, emits black smoke and drips. The treated thread on the right melts and drips, however, resists combustion and flaming, therefore, smoke is greatly reduced, retardant has done its job.

Read moreIndustrial yarns and threads are made of various fiber types and sizes which aresupplied on a wide range of package sizes with different lengths and yields. Most products are ordered by the pound, which may leave you wondering, “How long is it?” It’s important to understand the length and yield of your products to help improve your processing efficiency and waste reduction.

Read moreUnlike the September 2018 10 percent tariff, the additional 15 percent announced for shipments on or after May 10th may not have an immediate impact on the price of polyester yarn imports to the U.S.

Read moreWhat is Cotton Count?

- By Steve Zande

- 03/14/19

- 1 Comment

If you’ve come across the term Cotton Count and were a bit confused, you’re not alone. The terminology of the yarn and thread industry can be tricky.

Read moreThe Industrial Fabrics Foundation(IFF) has selected Service Thread for the 2018 Greater Good Award.

Read moreHow the Polyester Yarn Supply Chain is Impacted by the U.S. trade war with China

- By Torry Losch

- 09/21/18

- 0 Comments

On September 17th the United States Trade Representative (USTR) Office announced additional tariffs of 10 percent on 5,745 items with an approximate value of $200 billion USD. As most of the world is aware, the Trump Administration and China are in a heated economic battle.

Read moreTypically Mil Spec sewing thread standards are long and divided into several sections. They define physical characteristics of thread and are a good reference point for manufacturers however, they can be confusing and its important to understand the basics. Here is a quick guide to the 8 page standard, A-A-55195 (formerly MIL-T-44100) spun para-aramid sewing threads.

Read moreHow to Determine the Diameter (Thickness) and Width of Yarn or Thread

- By Eric Shippee

- 05/15/18

- 1 Comment

Thickness (or diameter) is one of the basic physical properties of textile materials. In certain industrial applications, the thickness may require rigid control within specified limits. Bulk and warmth properties of textile materials are often estimated from their thickness values, and thickness is also useful in measuring some performance characteristics, such as before and after abrasion and shrinkage.