A creel is simply a frame on which the feeding thread or yarn bobbin is fitted. Often, the creel is fitted with a yarn tensioning device which controls tension variation. Proper placement and stabilization of thread and yarn at the beginning of the product manufacturing process is critical. “Think of a creel as the foundation of a building,” states Neal Fournier, Facilities & Maintenance Manager with Service Thread. “It’s likely that process improvement starts after the yarn enters the production process; however, you will be surprised by the gains that can be made by taking a look at using a creel or refining your creel design.”

Read more- By Eric Shippee

- 07/19/17

- 1 Comment

- By Torry Losch

- 06/07/17

- 0 Comments

I’ve been in the industrial yarn business for 21 years and haven’t seen anything quite like the current polyester pricing situation. If you buy or sell synthetic yarns, I’m sure that you feel the same way. The fast pace of the modern business environment has impacted every market’s volatility, even the very mature ones (read “old textile businesses”).

Read more- By Eric Shippee

- 07/29/16

- 2 Comments

PTFE (polytetrafluoroethylene) is a thermoplastic polymer with a very low coefficient of friction along with excellent chemical, temperature, and environmental resistant properties. Commonly known by its brand names of Teflon™ , Yeumiflon® , or Profilen® , PTFE can be manufactured as a specialty fiber or thread for a broad range of applications including filtration, outdoor fabrics, electrical cables, and protective garments.

Read more

- By Dane Hatcher

- 03/04/16

- 0 Comments

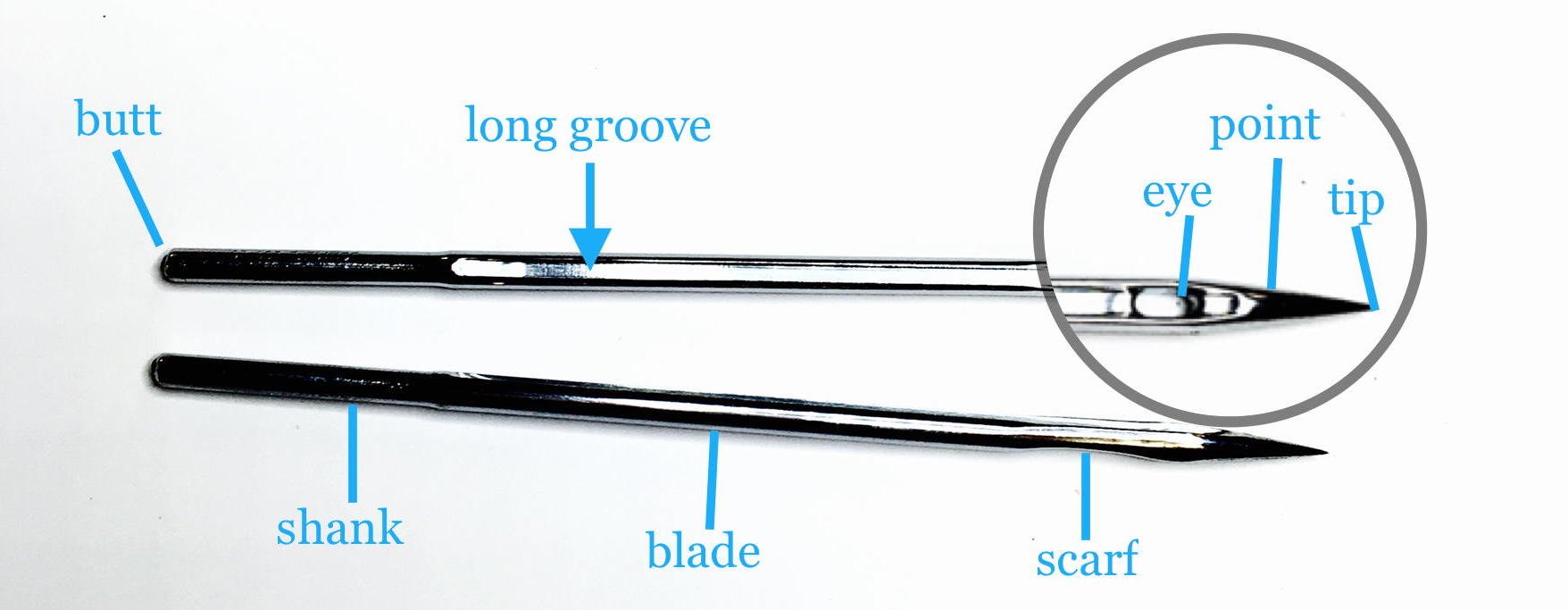

If your top thread is shredding or coming apart while sewing, this could indicate a common issue with the process. When the sewing machine pushes the needle through the material, it grabs the thread with a hook (or “looper”), while the needle rises back up. If there is a problem with this step it causes the thread to peel back, shred, break, flake, or not even get caught at all.

Read more- By Dane Hatcher

- 12/18/15

- 16 Comments

Until the 1940s, there were no standardized size designations for home or industrial needles; each manufacturer chose the sizing system they liked best and there were over 40 systems of sizing in use.

Read more- By Jay Todd

- 04/14/14

- 2 Comments

Should you be using a polypropylene or polyester sewing thread? We compare these two different materials to help you decide.

Read moreA creel is simply a frame on which the feeding thread or yarn bobbin is fitted. Often, the creel is fitted with a yarn tensioning device which controls tension variation. Proper placement and stabilization of thread and yarn at the beginning of the product manufacturing process is critical. “Think of a creel as the foundation of a building,” states Neal Fournier, Facilities & Maintenance Manager with Service Thread. “It’s likely that process improvement starts after the yarn enters the production process; however, you will be surprised by the gains that can be made by taking a look at using a creel or refining your creel design.”

Read moreI’ve been in the industrial yarn business for 21 years and haven’t seen anything quite like the current polyester pricing situation. If you buy or sell synthetic yarns, I’m sure that you feel the same way. The fast pace of the modern business environment has impacted every market’s volatility, even the very mature ones (read “old textile businesses”).

Read morePTFE (polytetrafluoroethylene) is a thermoplastic polymer with a very low coefficient of friction along with excellent chemical, temperature, and environmental resistant properties. Commonly known by its brand names of Teflon™ , Yeumiflon® , or Profilen® , PTFE can be manufactured as a specialty fiber or thread for a broad range of applications including filtration, outdoor fabrics, electrical cables, and protective garments.

Read more

If your top thread is shredding or coming apart while sewing, this could indicate a common issue with the process. When the sewing machine pushes the needle through the material, it grabs the thread with a hook (or “looper”), while the needle rises back up. If there is a problem with this step it causes the thread to peel back, shred, break, flake, or not even get caught at all.

Read moreUntil the 1940s, there were no standardized size designations for home or industrial needles; each manufacturer chose the sizing system they liked best and there were over 40 systems of sizing in use.

Read more

Should you be using a polypropylene or polyester sewing thread? We compare these two different materials to help you decide.

Read more