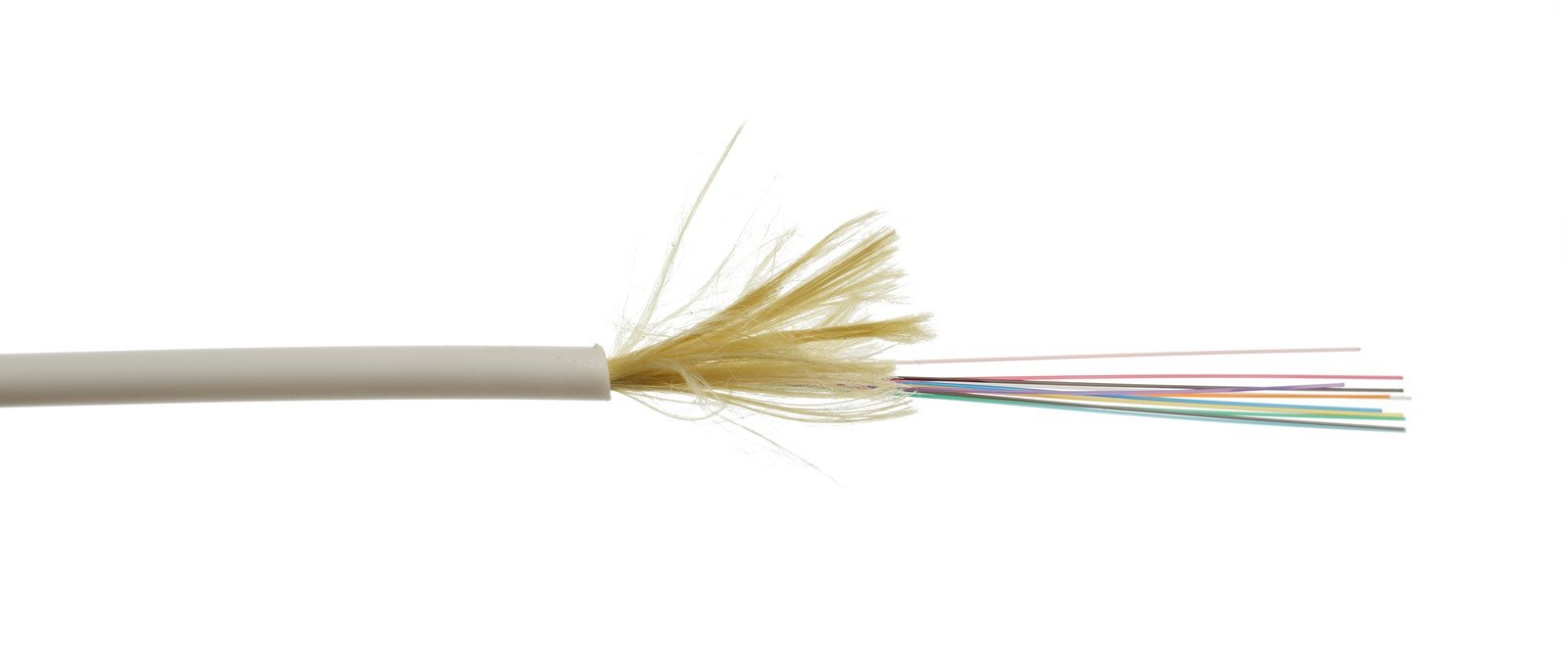

Every time you drive down the road and see suspended utility cables, you’re observing Young’s Modulus in action. The raised utility wires have a high modulus and are retaining their shape, even under the high pressures of aerial suspension and weather.

Read more- By Steve Zande

- 05/01/19

- 0 Comments

Trade tensions between the E.U. and the U.S. have continued to escalate after a preliminary list of $11 billion in tariffs was announced in April 2019. In response to European subsidies to Airbus and a subsequent World Trade Organization (WTO) ruling, U.S. textile importers have faced a duty of up to 100% on certain materials.

Read more- By Steve Zande

- 09/14/18

- 0 Comments

Typically Mil Spec sewing thread standards are long and divided into several sections. They define physical characteristics of thread and are a good reference point for manufacturers however, they can be confusing and its important to understand the basics. Here is a quick guide to the 8 page standard, A-A-55195 (formerly MIL-T-44100) spun para-aramid sewing threads.

Read more- By Steve Zande

- 07/27/18

- 0 Comments

When you are searching for a fiber or yarn for specific application requirements, there are many options to choose from. Meta-aramid and para-aramid yarns and threads are two popular choices for heat resistance and superior tensile strength.

Read more- By Eric Shippee

- 04/18/18

- 0 Comments

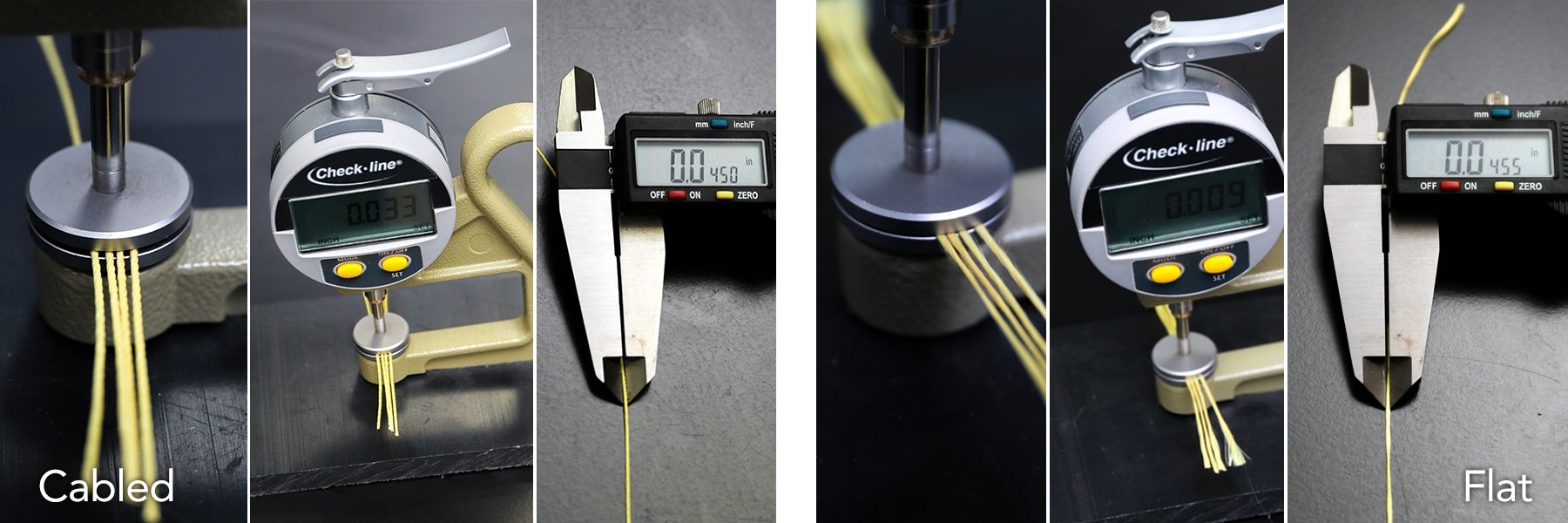

The relationship between yarn diameter and yarn size can be critical in determining the yarn or thread size needed to meet your requirements. A yarn or thread’s diameter and width can will affect the coverage of a yarn in a hose, how large of a yarn will fit into a wire or cable, and is important in determining the needle size required in industrial sewing applications.

Read more- By Steve Zande

- 03/20/18

- 0 Comments

Aramid fiber is best known by the trademark name DuPont™ Kevlar® and offers many unique and beneficial properties. With aramid raw material costs between five and thirty times the cost of nylon or polyester, many manufacturers look for ways to save when aramids are required for their application. What seems on the surface like an easy question is a lot more complicated than you might think. So, what are some of the factors that contribute to the total cost of industrial aramid yarn or thread?

Read more- By Eric Shippee

- 02/28/18

- 2 Comments

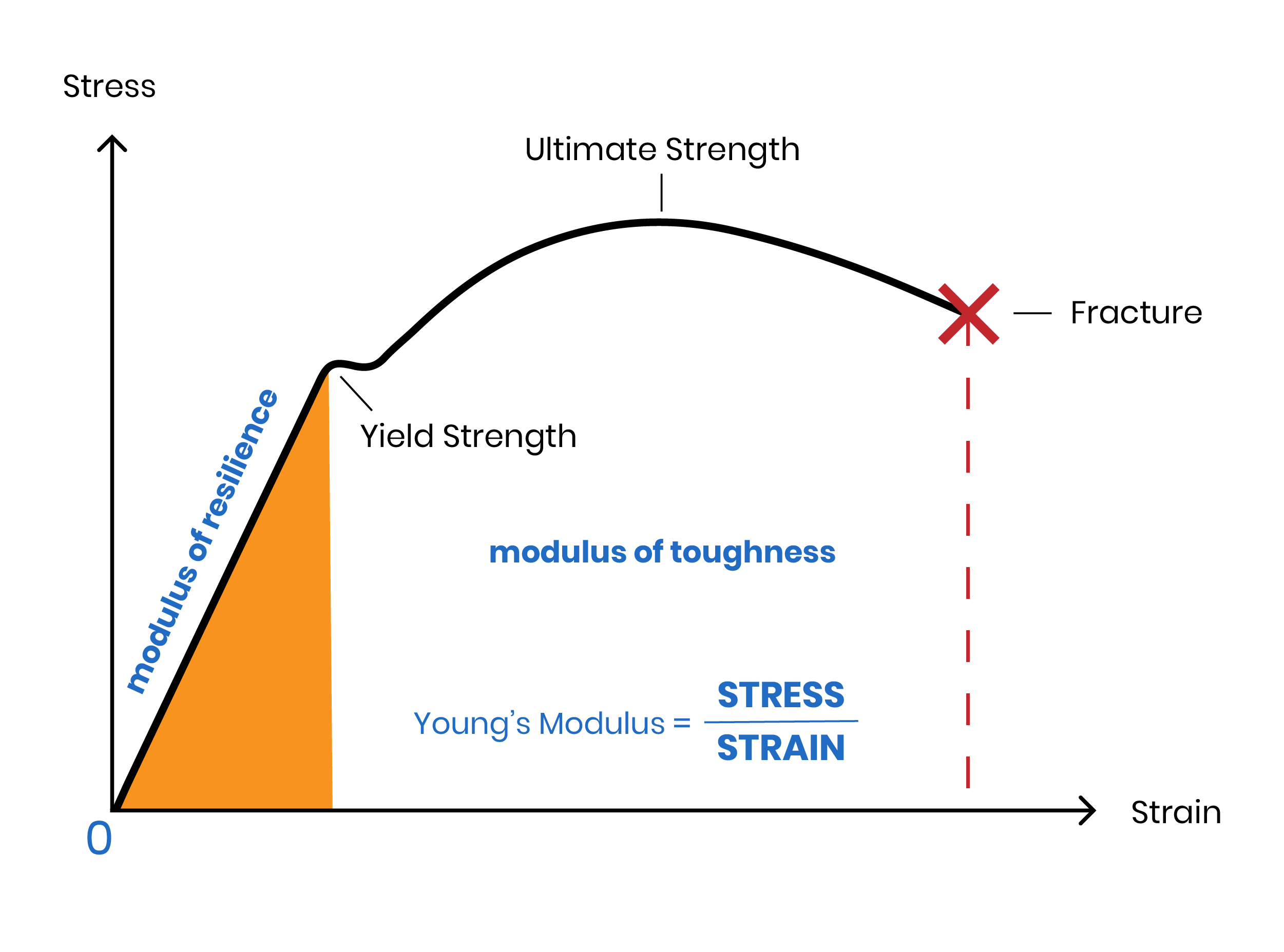

Tenacity and modulus are important characteristics to understand as they relate to industrial thread and yarn – particularly for applications in the wire and cable industry. They differ from one another in that tenacity is the ratio of tensile strength to yarn size. Tenacity is calculated using the ultimate breaking force of the yarn (when a thread or yarn is stretched to its breaking point) and the linear density and can be used to compare dissimilar material or different sizes of material.

Read moreEvery time you drive down the road and see suspended utility cables, you’re observing Young’s Modulus in action. The raised utility wires have a high modulus and are retaining their shape, even under the high pressures of aerial suspension and weather.

Read moreOlder Posts

What Do The Latest U.S. Trade Committee Hearings Mean for the Textile Industry?

- By Steve Zande

- 05/01/19

- 0 Comments

Trade tensions between the E.U. and the U.S. have continued to escalate after a preliminary list of $11 billion in tariffs was announced in April 2019. In response to European subsidies to Airbus and a subsequent World Trade Organization (WTO) ruling, U.S. textile importers have faced a duty of up to 100% on certain materials.

Read moreTypically Mil Spec sewing thread standards are long and divided into several sections. They define physical characteristics of thread and are a good reference point for manufacturers however, they can be confusing and its important to understand the basics. Here is a quick guide to the 8 page standard, A-A-55195 (formerly MIL-T-44100) spun para-aramid sewing threads.

Read moreWhen you are searching for a fiber or yarn for specific application requirements, there are many options to choose from. Meta-aramid and para-aramid yarns and threads are two popular choices for heat resistance and superior tensile strength.

Read moreThe relationship between yarn diameter and yarn size can be critical in determining the yarn or thread size needed to meet your requirements. A yarn or thread’s diameter and width can will affect the coverage of a yarn in a hose, how large of a yarn will fit into a wire or cable, and is important in determining the needle size required in industrial sewing applications.

Read moreAramid fiber is best known by the trademark name DuPont™ Kevlar® and offers many unique and beneficial properties. With aramid raw material costs between five and thirty times the cost of nylon or polyester, many manufacturers look for ways to save when aramids are required for their application. What seems on the surface like an easy question is a lot more complicated than you might think. So, what are some of the factors that contribute to the total cost of industrial aramid yarn or thread?

Read moreStandard Tenacity Yarn vs. High Modulus Aramid Yarn – Which Do You Need?

- By Eric Shippee

- 02/28/18

- 2 Comments

Tenacity and modulus are important characteristics to understand as they relate to industrial thread and yarn – particularly for applications in the wire and cable industry. They differ from one another in that tenacity is the ratio of tensile strength to yarn size. Tenacity is calculated using the ultimate breaking force of the yarn (when a thread or yarn is stretched to its breaking point) and the linear density and can be used to compare dissimilar material or different sizes of material.

Read more