When sewing, is your needle heating up and causing damage to your thread or material, compromising the strength of your seams?

Read more- By Dane Hatcher

- 05/11/21

- 0 Comments

Your Class 7 Style sewing machine is an asset to your operations; one that needs careful maintenance to keep it in proper working order.

Read more- By Dane Hatcher

- 03/16/21

- 0 Comments

- By Dane Hatcher

- 03/12/21

- 0 Comments

If an industrial sewing machine operator is sewing with excessive tension, it can literally stretch the thread as it’s being sewn and weaken the seam, which compromises the integrity of the product that’s being sewn.

Read more- By Dane Hatcher

- 03/09/21

- 0 Comments

If you are breaking in a brand new Class 7 sewing machine, it’s important to oil it correctly while it is still new, during your first months of use. Otherwise, the machine will lock up and stop working properly.

Read more- By Dane Hatcher

- 01/04/21

- 0 Comments

Are you wondering whether its more beneficial for you to wind your own bobbins in-house or purchase pre-wound bobbins from a thread manufacturer?

Read more- By Dane Hatcher

- 10/23/20

- 0 Comments

Checking your sewing thread regularly is the best way to prevent wearing and shedding that can harm your sewing process.

In this video, Service Thread Sewing Sales and Tech Support Manager Dane Hatcher demonstrates how to check your thread for UV damage, look for bond separation, examine the twist level, check the bobbin tack, and make sure you have enough lube in the top thread.

Read more- By Dane Hatcher

- 09/15/20

- 0 Comments

You can determine sewing speed without using any type of specialized tools. Simply follow the steps outlined below.

Read more- By Dane Hatcher

- 08/28/20

- 0 Comments

If your machine’s tension is wrong, you’ll deal with thread shedding, pulling, and breakage, plus poor stitch quality.

In this video from our troubleshooting series, Service Thread Sewing Sales and Tech Support Manager Dane Hatcher demonstrates how to adjust your bobbin tension, how to avoid common mistakes, and how to know when the tension is just right.

Read more- By Dane Hatcher

- 08/21/20

- 0 Comments

Do you have lint or lubrication buildup in your industrial sewing machine’s shuttle?

In this video, Service Thread Sewing Sales and Tech Support Manager Dane Hatcher demonstrates how to remove the shuttle and shuttle race, then perform a quick examination and cleaning routine that ensures your machine is in good working order.

Read moreWhen sewing, is your needle heating up and causing damage to your thread or material, compromising the strength of your seams?

Read moreOlder Posts

Service Class 7 Troubleshooting Series: Cleaning a Class 7 Style Sewing Machine

- By Dane Hatcher

- 05/11/21

- 0 Comments

Your Class 7 Style sewing machine is an asset to your operations; one that needs careful maintenance to keep it in proper working order.

Read moreIntro to Sewing Industrial Webbing

- By Dane Hatcher

- 03/16/21

- 0 Comments

If an industrial sewing machine operator is sewing with excessive tension, it can literally stretch the thread as it’s being sewn and weaken the seam, which compromises the integrity of the product that’s being sewn.

Read moreOiling a Class 7 Sewing Machine

- By Dane Hatcher

- 03/09/21

- 0 Comments

If you are breaking in a brand new Class 7 sewing machine, it’s important to oil it correctly while it is still new, during your first months of use. Otherwise, the machine will lock up and stop working properly.

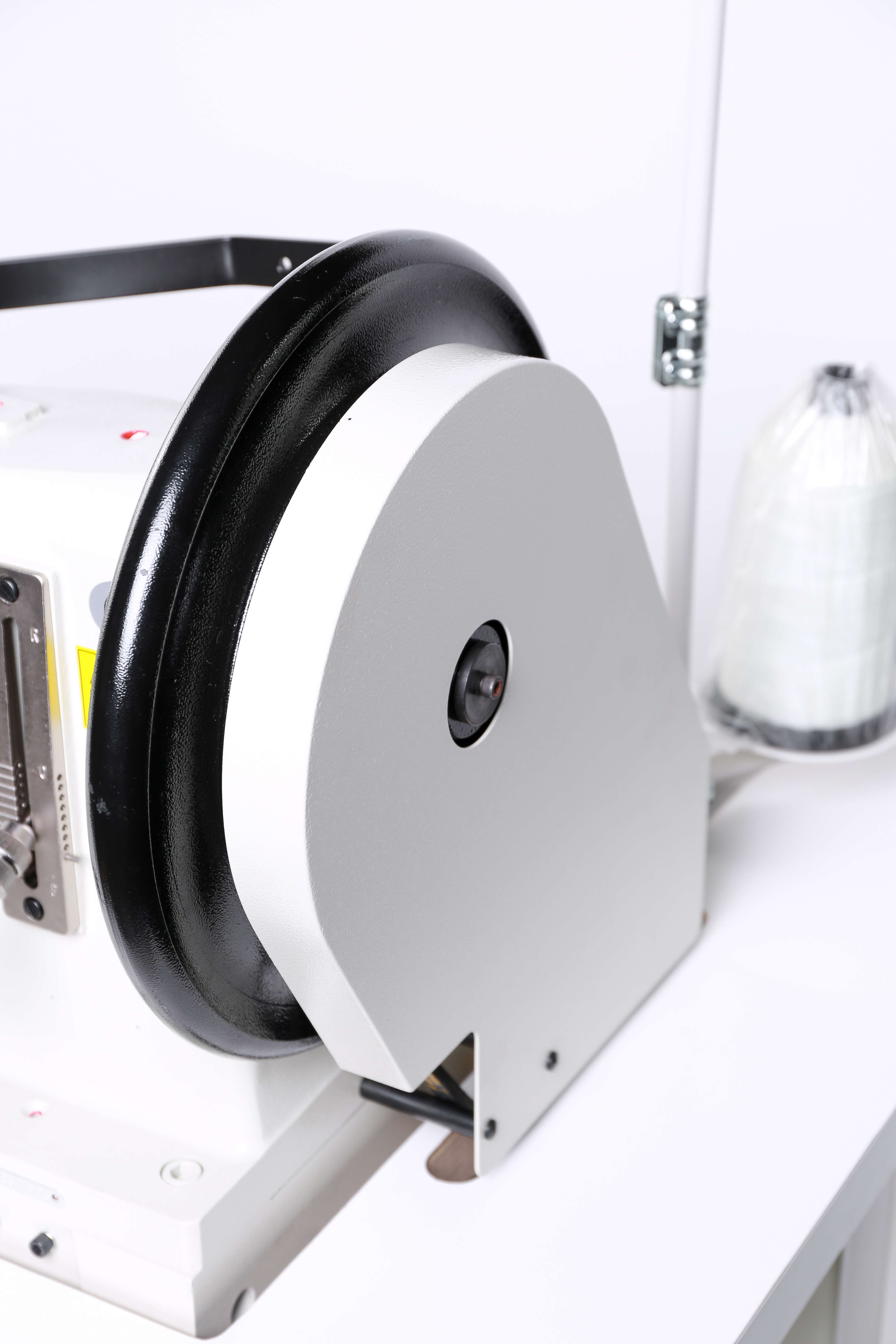

Read moreWinding Bobbins vs. Using Pre-wound Bobbins for Heavy Duty Sewing Applications

- By Dane Hatcher

- 01/04/21

- 0 Comments

Are you wondering whether its more beneficial for you to wind your own bobbins in-house or purchase pre-wound bobbins from a thread manufacturer?

Read moreChecking your sewing thread regularly is the best way to prevent wearing and shedding that can harm your sewing process.

In this video, Service Thread Sewing Sales and Tech Support Manager Dane Hatcher demonstrates how to check your thread for UV damage, look for bond separation, examine the twist level, check the bobbin tack, and make sure you have enough lube in the top thread.

Read moreYou can determine sewing speed without using any type of specialized tools. Simply follow the steps outlined below.

Read moreTroubleshooting Series - Industrial Sewing Tension Setting Tutorial

- By Dane Hatcher

- 08/28/20

- 0 Comments

If your machine’s tension is wrong, you’ll deal with thread shedding, pulling, and breakage, plus poor stitch quality.

In this video from our troubleshooting series, Service Thread Sewing Sales and Tech Support Manager Dane Hatcher demonstrates how to adjust your bobbin tension, how to avoid common mistakes, and how to know when the tension is just right.

Read moreTroubleshooting Series - Industrial Sewing Shuttle Maintenance Tutorial

- By Dane Hatcher

- 08/21/20

- 0 Comments

Do you have lint or lubrication buildup in your industrial sewing machine’s shuttle?

In this video, Service Thread Sewing Sales and Tech Support Manager Dane Hatcher demonstrates how to remove the shuttle and shuttle race, then perform a quick examination and cleaning routine that ensures your machine is in good working order.

Read more

.jpg)