You can determine sewing speed without using any type of specialized tools. Simply follow the steps outlined below.

Simply follow the steps outlined below.

Calculate Stitches Per Minute:

1. Motor RPM: Find the plate on your machine motor and look for the rate at which it runs. This is the motor rpm.

2. Motor Pulley Diameter: Measuring your motor pulley diameter can be accomplished by wrapping a belt around the pulley and using a tape measure. Check its outside diameter with the belt in place and note this measurement.

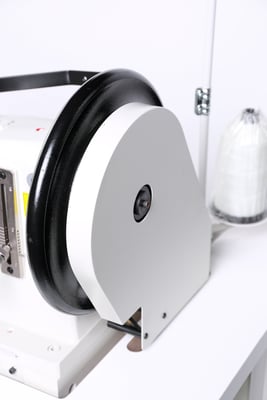

3. Sewing Head Pulley Diameter: Measuring your sewing head pulley diameter can be accomplished by wrapping a belt around the pulley and using a tape measure. Check its outside diameter with the belt in place and note this measurement.

4. Reduction Ratio: To calculate reduction ratio, divide your sewing head pulley measurement by the motor pulley diameter.

Example:

Assume that your motor runs at 1725 rpm, your motor pulley diameter is 2.5 inches, and your sewing head pulley diameter is 10 inches.

10/2.5 = 4

Your reduction ratio is 4

5. Stitches Per Minute or Sewing Head RPM:

The stitches per minute is how fast the head is rotating with every rotation making a single stitch. To calculate the stitches per minute divide the motor rpm by your reduction ratio.

Example:

1725/4 = 431.25

Your stitches per minute or sewing head rpm is 431.25

Once you’ve calculated your stitches per minute, you can determine your stitch length and sewing speed.

Calculating Stitch Length and Sewing Speed

1. Stitches Per Inch: Locate a piece of test material and sew along it for several inches. Take a tape measure or ruler and hold it against the stitching, counting how many stitches you have in exactly 2 inches. Take this number and divide it by 2. This is your stitches per inch.

2. Stitches Per Minute or Sewing Head RPM: Use the instructions above to calculate the sewing head rpm or stitches per minute.

3. Stitch Length and Sewing Speed: To calculate the inches sewn per minute use the stitches per inch that you measured and divide by sewing head rmp, and then divide that by your reduction ratio.

Example:

Assume you have 4 stitches per inch. Now go back and look at your sewing head rpm, which in our example was 431.25. Divide the sewing head rpm by your ratio.

431.25/4 = 107.8125

Your inches sewn per minute is 107.8125

Now you know how many inches will be sewn each minute at this stitch length, or inches per minute (IPM). Longer stitches cover more fabric faster, so if your stitches per inch measurement was 3 instead of 4, your inches per minute would be 431.25/3 = 143.75.

As you can see, this means you can increase the length of your stitch to move faster in your sewing, but there is also another factor to consider. Longer stitches are less strong, creating a weaker seam than shorter stitches would create.

Be careful not to weaken your seams beyond specifications. Try to find a balance of speed to seam strength. A thicker, stronger thread can help offset some seam strength loss when operating at a longer stitch length, so this is something to consider if your sewing process needs to be very fast.

Service Thread offers strong industrial yarn and thread options that hold up at fast speeds. Contact us if you need help choosing the best product for your application. We’re always here to help!