Are you using the right industrial sewing machine? Things to consider when looking to purchase a new machine include stitch type, thread thickness, sewing material thickness, material density, speed, parts availability, warranty, and special features or abilities.

Read more- By Dane Hatcher

- 06/22/20

- 0 Comments

- By Dane Hatcher

- 05/28/20

- 0 Comments

Is your industrial sewing process affected by thread skips, breaks, and shedding? In our latest video tutorial, Service Thread Sewing Sales & Tech Support Manager, Dane Hatcher demonstrates how to avoid thread problems by properly adjusting your machine.

Read more- By Dane Hatcher

- 04/15/20

- 0 Comments

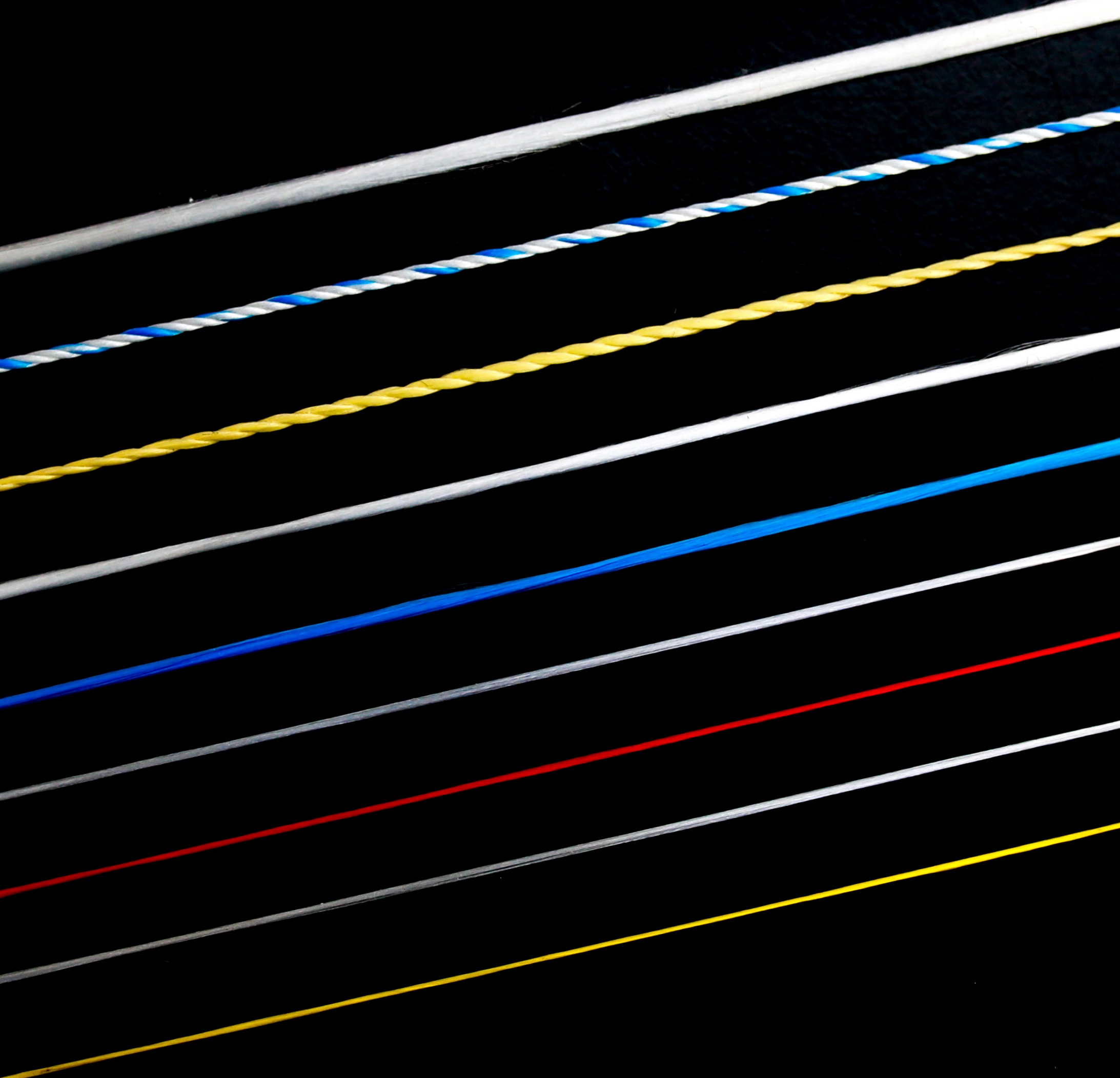

When industrial sewing operations require high thread or yarn tensions, properly designed sewing threads and yarns are critical to continuous production flow. Bonded sewing thread and yarn tends to perform well for critical and challenging sewing conditions often faced by manufacturing companies. We’d like to provide some insight into how bonded thread affects tension in industrial sewing and manufacturing.

Read more- By Dane Hatcher

- 04/06/20

- 0 Comments

It’s important to evaluate whether you should be using a bonded or non-bonded thread in your industrial sewing process. For manufacturers, each type of industrial sewing thread or yarn has its own set of advantages and disadvantages, so let’s take a closer look at each option and which might be right for your application.

Read more- By Service Thread

- 03/23/20

- 0 Comments

When you’re sewing at high speeds, bonded thread prevents snags and breaks that cause production interruptions and create flaws in your products. In many applications, bonded sewing thread is almost always a superior choice.

Read moreChoosing the Correct Industrial Sewing Machine for Your Application

- By Dane Hatcher

- 06/22/20

- 0 Comments

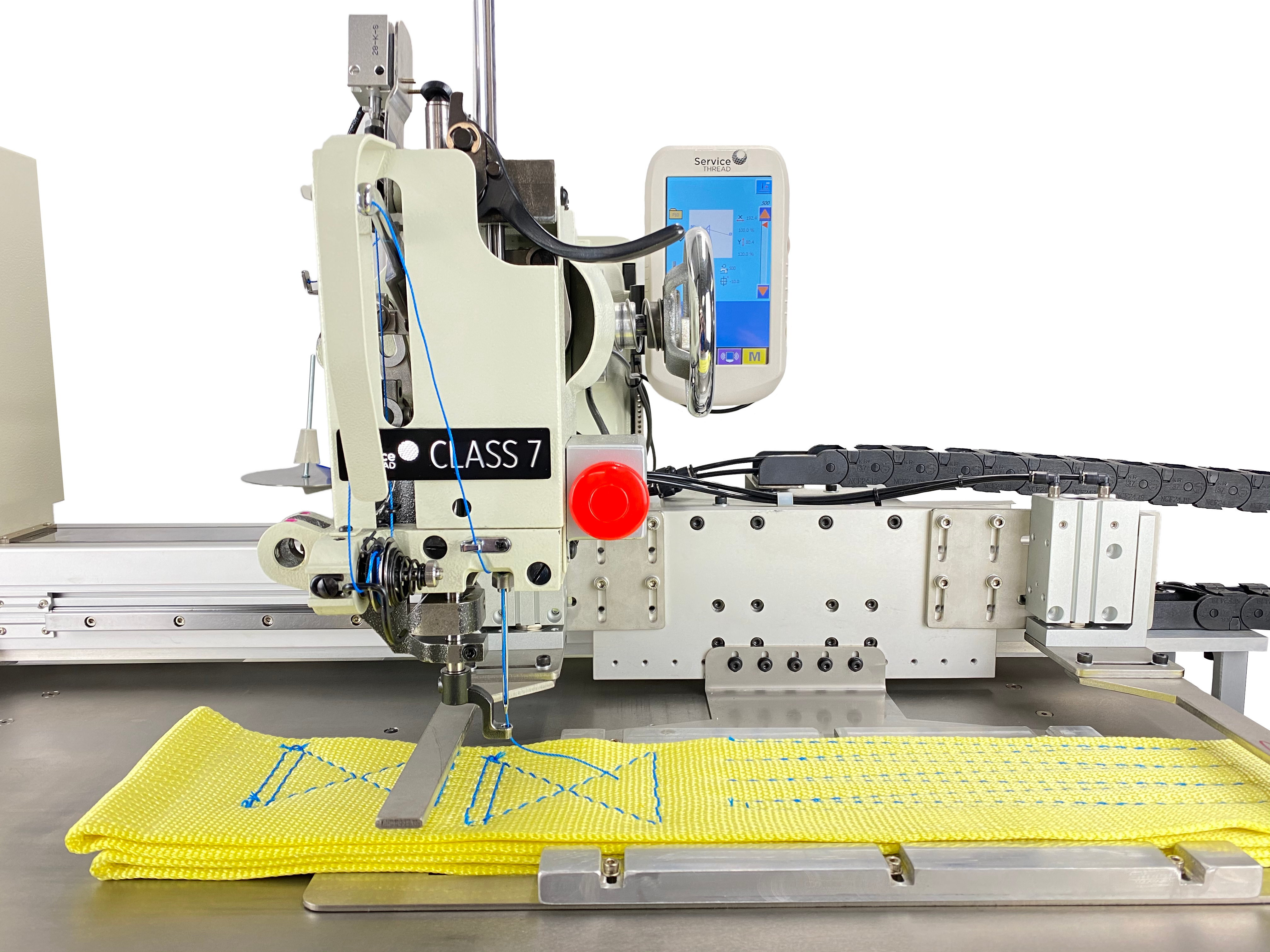

Are you using the right industrial sewing machine? Things to consider when looking to purchase a new machine include stitch type, thread thickness, sewing material thickness, material density, speed, parts availability, warranty, and special features or abilities.

Read moreTroubleshooting Series - Service Class 7 Troubleshooting Video Guide

- By Dane Hatcher

- 05/28/20

- 0 Comments

Is your industrial sewing process affected by thread skips, breaks, and shedding? In our latest video tutorial, Service Thread Sewing Sales & Tech Support Manager, Dane Hatcher demonstrates how to avoid thread problems by properly adjusting your machine.

Read moreWhat Effect Does Bonded Thread Have On Tensions in a Sewing Application?

- By Dane Hatcher

- 04/15/20

- 0 Comments

When industrial sewing operations require high thread or yarn tensions, properly designed sewing threads and yarns are critical to continuous production flow. Bonded sewing thread and yarn tends to perform well for critical and challenging sewing conditions often faced by manufacturing companies. We’d like to provide some insight into how bonded thread affects tension in industrial sewing and manufacturing.

Read moreIt’s important to evaluate whether you should be using a bonded or non-bonded thread in your industrial sewing process. For manufacturers, each type of industrial sewing thread or yarn has its own set of advantages and disadvantages, so let’s take a closer look at each option and which might be right for your application.

Read moreWhen you’re sewing at high speeds, bonded thread prevents snags and breaks that cause production interruptions and create flaws in your products. In many applications, bonded sewing thread is almost always a superior choice.

Read more