Are you using the right industrial sewing machine? Things to consider when  looking to purchase a new machine include stitch type, thread thickness, sewing material thickness, material density, speed, parts availability, warranty, and special features or abilities.

looking to purchase a new machine include stitch type, thread thickness, sewing material thickness, material density, speed, parts availability, warranty, and special features or abilities.

Know Your Stitch Type

There are several stitch types used for various applications, so it’s important to know the correct stitch type to use for your product.

Knowing the stitch type you need, use this as one metric to filter out machines that do not form this stitch. Also, note the stitch length and ensure the machine can handle the stitch the length you need to meet your strength requirements.

The next consideration should be the thread thickness you need to use in your product. Some machines cannot handle large thread and some are better suited to small thread. If the manufacturer does not specify the thread size range, find the needle system of the machine.

From there, you can look up the needle sizes offered in that system. For help understanding needle systems, see my blog post here and for help with needle-to-thread sizing, see my blog post here.

Material Thickness and Density

Next, consider your material thickness and density. If your material is very thick, you will need a machine that has enough foot lift for the material to fit under the needle. If your material is very dense, you need a machine strong enough to punch through it.

Generally, the larger machines that can handle very large threads are going to be slower than the smaller machines. A larger machine will be a better choice if you have very dense material because a large machine is made of stronger parts that can handle the abuse of beating a needle through dense material.

A smaller machine may be able to do it, but when running faster, it may see more wear and parts breakage. If your material is thin or loose, the smaller and faster machine will equate to more production capability.

After you’ve settled on a few machine options, identify any special-use applications that can change the machine. For example, very large fabrics like pool covers or tarps require a long arm. Tight-radius products like footballs require a cylinder arm or post bed. Repetitive patterns usually require an automated machine.

Are there any special features you may need? These might include a fabric fence, puller, pre-tensioner, servomotor, needle cooler, and so forth. Check with the supplier to see if they’re willing to modify or add anything to the machine for your needs.

Parts and Warranties

Now review the parts availability and the warranties for the machines you’re considering. If your production line is running and something breaks within the warranty period, does the supplier have the part on hand? How long will it be under warranty? How long will it take to receive replacement parts when you order them?

When choosing a machine, spare parts availability is something that is often overlooked. If parts take weeks or months to get, your operation may be down during that period, so it is important to verify that parts are available and in a timely manner.

Examples of Good Matches Between Machines and Products

Let’s look at a few examples of sewn products and which sewing machine is capable of handling that product.

Paper and Plastic Bags

First up, for sewing paper or plastic bags in the field, like a feed bag or vegetable bag, you’ll need a 101 chainstitch and 12/5 thread. The bags are thin and not dense, so a fast and light machine is what you’d look for.

Give special consideration to the fact that the machine must be easily portable and lightweight to carry, as well as move across the top of a bag. For these purposes, a portable bag closer such as the Fischbein Model F, Newlong NP-7, or Service Thread PBC would be the best fit.

Synthetic Lifting Sling

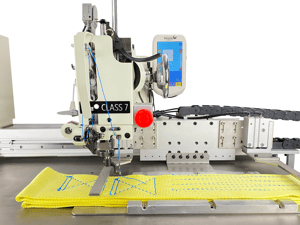

Next’s let’s look at a synthetic lifting sling. For this product, a 301 lockstitch would be needed along with a larger cabled thread such as 415 nylon. Lifting slings can be thick and, if using edge protection, can be dense. A large heavy-duty sewing machine is needed, such as the Service Thread Class 7, Consew 733R, Seiko 2B, and Singer 7-33.

Tarps and Large Products

If you are sewing tarps or large fabrics, you will use a medium-weight thread and thin fabrics. Depending on the use of the product, they can be sewn with a 401 chainstitch if it is a one-time use product, or the 301 lockstitch if it is a reusable product.

A long-arm machine will be best for large fabrics or tarps where several panels must be sewn together. Suitable machines for this use are the Service Thread Extra Long Arm Class 7, Adler 220, Consew 744R, 745R, Juki LG-158, Singer 144W, and Singer 300W.

Using this guide, you should know what to look for when searching for an industrial machine to process your product. If you need any further information, Service Thread can help!