When yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

When yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

Water is the most common cause of premature failure of cable and electrical equipment. Performing a water absorbency test on industrial yarns will provide you with the information needed to make the best choices regarding the type of yarn and protective applications used for your product. Water and moisture get into cables in two common ways:

Radical Ingress: This occurs when moisture enters the cable by soaking through protective layers or through a weakening or hole in the protective sheath. Once the water enters it will travel down the cable in a longitudinal way.

Longitudinal Ingress: When capping is done poorly or joints and splices are made wrong, water can enter a cable.

Testing the absorbency of a material can prevent damage and save you money in the long run, learning to evaluate water absorbing characteristics will allow you to choose the best material for your product’s unique needs.

Getting Started

Equipment Needed

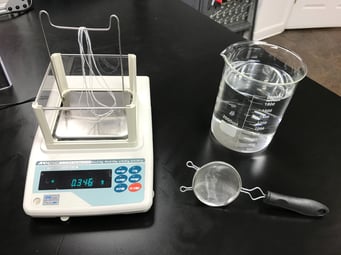

To properly perform this test you will need access to a hot air oven, and an analytical balance that is able to measure to 0.001 grams. This test also requires a container to hold water in, a strainer or sieve and a digital timer. Lastly, you will need the materials that will be tested.

The Water Absorbency Test Procedure

Begin by cutting three one-meter lengths of the material being tested. Once they are ready place the samples of material in a hot air oven for 30 minutes to ensure that the samples are completely dry. While waiting for the materials to be ready, fill your container with tap water. Then record the tare weight of the sieve or strainer being used in this test. Once the materials are ready, remove one test sample from the oven and immediately place it in the strainer. Then place the strainer and material sample on the analytical balance. Subtract the tare weight of the strainer and record this value as the dry weight of the material.

Now submerge the strainer containing the yarn sample inside the water filled container for 2 minutes. When ready, remove strainer from water and allow excess water to drain for 1 minute. Once it is completely drained, weigh the strainer containing wet yarn sample. Subtract tare weight of the strainer and record this value as the wet weight of the material. Repeat these steps with the two remaining samples.

You will then calculate the absorbency of each sample of yarn by using the following formula:

(Wet weight - Dry Weight) / Dry Weight = Absorbency (g/g)

Record the average absorbency of the three samples as the final test result.

Test Variations

This is a very basic testing method and could be altered to satisfy different queries. For example, you could test time related differentiations and test the absorption in 1 minute versus 10 minute intervals to see if it swells faster or if the yarn diameter swells bigger. The water itself can even be switched with something like saline solution if that pertained to your particular product.

If you’re looking for other methods to test the efficiency of yarns, cables or wires, review our other helpful resources here:

- What is ASTM D4974? Hot Air Shrinkage Test for Yarn Cord Explained

- How to Test Non-Wicking Properties of Yarns and Fibers for Wire and Cable

- Waterblocking Yarns and Threads for Wire and Cable

Service Thread has an extensive inventory of multi-filament yarns which would be a cost efficient waterblocking solution for the manufacturing of wire and cable. We take great pride in engineering yarns and sewing threads designed to solve your specific product and processing problems. Contact us to see how we can be of service to you.