If you manufacture hoses, cables, or sewn products, yarn diameter or gauge is an important factor in determining what industrial yarn or thread type and construction to use. Not to be confused with the linear density or size of the material, yarn gauge is the measured thickness of a cross section of material.

Read more- By Eric Shippee

- 10/02/15

- 1 Comment

Control of static and current electricity is a crucial consideration in industrial product design. By using combinations of different polymers and coatings, industrial yarn and threads can be designed to help conduct or impede electrical charges as required for different product applications.

Read more- By Steve Zande

- 09/04/15

- 0 Comments

Twist can impact the dynamics of your final product in many ways – strength, elongation, diameter, torque, lustre, softness etc. Unlike staple spun yarns, multifilament yarns lose strength as the twist is increased, therefore it is important to know the physical requirements required in the end product. Elongation increases with increasing twist, as does diameter, torque and lustre. Yarns become stiffer with twist therefore softness decreases.

Read more- By Steve Zande

- 08/14/15

- 4 Comments

When setting out to find the best industrial high tenacity polyester, it's important to know and understand the key physical properties you are looking for, and to understand the units of measure being presented for each one. The table below contains a list of some of the largest polyester yarn producers in the world, as well as a list of polyester yarn specifications for specific types of their 1000 Dn (1100 dtex) high tenacity standard polyester yarns.

Read more- By Steve Zande

- 07/31/15

- 1 Comment

Dupont™ Kevlar®and other aramid yarns and threads are used in many industries including:

- high temperature fluid hose manufacturing as reinforcement

- electrical wire and cable for binding, ripcords, strength members and shielding (braided)

- composite materials- aramid fabric is used for strength and reinforcement

- ballistics, to sew proctective garmets, body armour and bullet proof vests

- rope manufacturing for added strength

- synthetic web-slings for sewing and round sling filler yarn

- mattress manufacturing for sewing tape edge seams

Most of the products made with Kevlar® and other aramid yarns require high strength and/or fire retardant characteristics. The unique nature and production processes to make aramid fibers are some reasons aramids are much more expensive than other commodity fibers like cotton, polyester and nylon. Common characteristics among Kevlar® and other Aramid fibers include:

Read more- By Service Thread

- 09/17/13

- 0 Comments

As discussed earlier, there is nothing worse than trying to handle a torque/tension filled lively, kinky yarn or thread. Each step of a manufacturing process such as twisting, spinning etc. causes tension in fiber, filament, yarn and thread. Yarns tend to snarl/kink up in order to relax and rid themselves of tension. Uncontrolled tension and subsequent snarling & kinking are likely to create manufacturing issues for our customers, and we do not want that!

Read more- By Service Thread

- 06/12/13

- 0 Comments

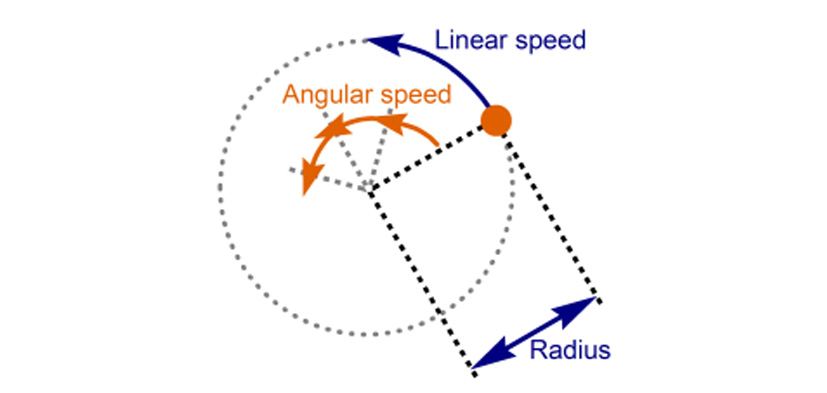

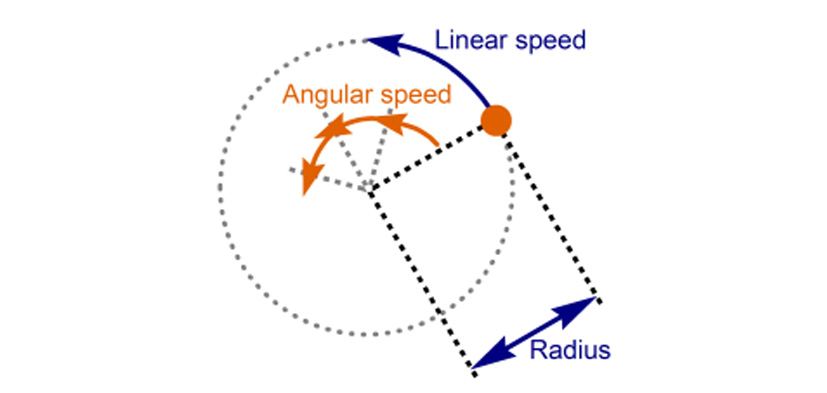

One of our partners, a small-gauge hose manufacturing plant that runs around the clock, wanted to produce more product in less time. But their solution, to run machines 22% faster, caused our yarn cones to break and blow out. I visited the plant, where I used quantitative measures to determine what parameters may be optimum for even higher angular speeds and therefore greater out-puts.

Read more- By Eric Shippee

- 08/24/12

- 0 Comments

Have you ever needed more of a specific material, but weren’t sure what it was made of? There is a very simple test that anyone can perform to identify which fibers are in a material in mere seconds. All it takes is a sample of yarn…and a little fire.

Read more- By Neal Fournier

- 07/27/12

- 0 Comments

I’ll discuss different types of guides and recommend our favorite, ceramic!

Choosing the right yarn or thread guide for the product and process is one of the key factors that can influence the quality and efficiency of any production operation using industrial textiles.

Read moreIf you manufacture hoses, cables, or sewn products, yarn diameter or gauge is an important factor in determining what industrial yarn or thread type and construction to use. Not to be confused with the linear density or size of the material, yarn gauge is the measured thickness of a cross section of material.

Read moreConductive and Non Conductive Yarns

- By Eric Shippee

- 10/02/15

- 1 Comment

Control of static and current electricity is a crucial consideration in industrial product design. By using combinations of different polymers and coatings, industrial yarn and threads can be designed to help conduct or impede electrical charges as required for different product applications.

Read moreTwist can impact the dynamics of your final product in many ways – strength, elongation, diameter, torque, lustre, softness etc. Unlike staple spun yarns, multifilament yarns lose strength as the twist is increased, therefore it is important to know the physical requirements required in the end product. Elongation increases with increasing twist, as does diameter, torque and lustre. Yarns become stiffer with twist therefore softness decreases.

Read moreGeneral Specs: Best High Tenacity Polyester Yarn Suppliers Compared

- By Steve Zande

- 08/14/15

- 4 Comments

When setting out to find the best industrial high tenacity polyester, it's important to know and understand the key physical properties you are looking for, and to understand the units of measure being presented for each one. The table below contains a list of some of the largest polyester yarn producers in the world, as well as a list of polyester yarn specifications for specific types of their 1000 Dn (1100 dtex) high tenacity standard polyester yarns.

Read moreDupont™ Kevlar®and other aramid yarns and threads are used in many industries including:

- high temperature fluid hose manufacturing as reinforcement

- electrical wire and cable for binding, ripcords, strength members and shielding (braided)

- composite materials- aramid fabric is used for strength and reinforcement

- ballistics, to sew proctective garmets, body armour and bullet proof vests

- rope manufacturing for added strength

- synthetic web-slings for sewing and round sling filler yarn

- mattress manufacturing for sewing tape edge seams

Most of the products made with Kevlar® and other aramid yarns require high strength and/or fire retardant characteristics. The unique nature and production processes to make aramid fibers are some reasons aramids are much more expensive than other commodity fibers like cotton, polyester and nylon. Common characteristics among Kevlar® and other Aramid fibers include:

Read moreTop Processing Cure for Excessive Twist and Torque in Twisted Yarn: Conditioned Heat Setting

- By Service Thread

- 09/17/13

- 0 Comments

As discussed earlier, there is nothing worse than trying to handle a torque/tension filled lively, kinky yarn or thread. Each step of a manufacturing process such as twisting, spinning etc. causes tension in fiber, filament, yarn and thread. Yarns tend to snarl/kink up in order to relax and rid themselves of tension. Uncontrolled tension and subsequent snarling & kinking are likely to create manufacturing issues for our customers, and we do not want that!

Read moreHigh Speed Spiral Winding-Measure Yarn Cone Density and Increase Line Speeds

- By Service Thread

- 06/12/13

- 0 Comments

One of our partners, a small-gauge hose manufacturing plant that runs around the clock, wanted to produce more product in less time. But their solution, to run machines 22% faster, caused our yarn cones to break and blow out. I visited the plant, where I used quantitative measures to determine what parameters may be optimum for even higher angular speeds and therefore greater out-puts.

Read more

Have you ever needed more of a specific material, but weren’t sure what it was made of? There is a very simple test that anyone can perform to identify which fibers are in a material in mere seconds. All it takes is a sample of yarn…and a little fire.

Read moreAn Easy and Immediate Upgrade for Industrial Yarn Processing Equipment

- By Neal Fournier

- 07/27/12

- 0 Comments

I’ll discuss different types of guides and recommend our favorite, ceramic!

Choosing the right yarn or thread guide for the product and process is one of the key factors that can influence the quality and efficiency of any production operation using industrial textiles.

Read more