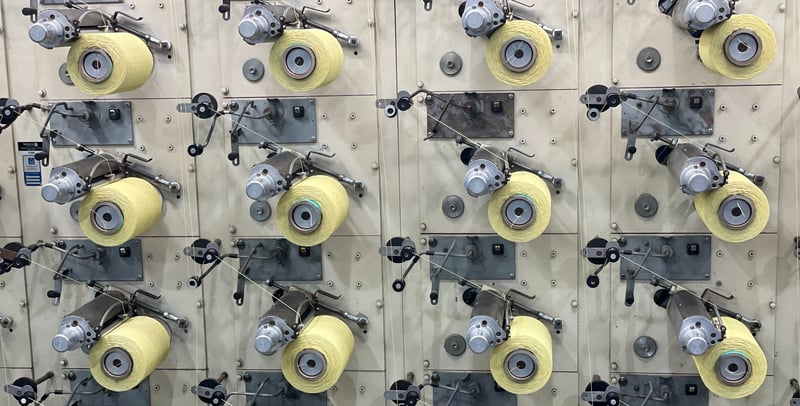

Quality yarns for wire and cable manufacturing

Service Thread designs and supplies high-quality binder yarns, ripcord threads, and aramid yarn strength members to exceed abrasion resistance, processing speed, yield, gauge, and weight. Our propitiatory water absorbing swellable yarns and non-wicking textile yarns are designed to run clean, with less build-up powdering, and processing issues than most older product designs.

We’re a U.S.-based, global leader in developing and manufacturing engineered yarns and threads. We help wire and cable manufacturers solve material availability and textile processing challenges by sharing our knowledge, global supply chain partnerships and advanced processing techniques.

Customers who value quality, reliability, technical support and short lead times for their technical yarns needs, choose Service Thread.

Improve your products and processes with:

- High-quality, precision wound product design

- Variety of packages types and sizes

- Product and process technical support

- Same-day shipping

Common treatments and coatings available for wire & cable

- Swellable - Super absorbent coating designed to block water penetration

- Non-Wicking - Hydrophobic treatment designed to prevent water migration. Typical water migration is less than one inch vertically in a six hour period

- Abrasion Resistant - Treatment for ripcords allowing for easier, more consistent ripping without breakage. Designed with armor jacketed cables in mind

- Waxed Treatment - Various waxes applied to aid in stiffness and tackiness of material - primarily for cable harness tying

Ripcords for every purpose

As an ISO 9001:2015 registered U.S. manufacturer, we offer high-performance abrasion resistant ripcords designed to pull through armored jackets easily with no breaks or hang-ups.

Here are some of properties of our most popular ripcords:

Nylon Ripcords

| Common Nylon Ripcord Constructions |

Strength (lbs) | Yield (yds/lb) |

Diameter (in) |

Elongation |

| Monocord | ||||

| 840/1 Nylon | 18 | 5,300 | 0.0080 | 20 % |

| 1050/1 Nylon | 20 | 4,250 | 0.0100 | 22 % |

| 1260/1 Nylon | 28 | 3,500 | 0.0110 | 20 % |

| Cabled | ||||

| 840/1/2 Nylon | 34 | 2,650 | 0.0200 | 21 % |

| 1260/1/4 Nylon | 112 | 885 | 0.0420 | 20 % |

| 1680/2/3 Nylon | 220 | 450 | 0.0550 | 22 % |

* variety of Other fibers and constructions available upon request

Polyester Ripcords

| Common Polyester Ripcord Constructions |

Strength (lbs) | Yield (yds/lb) |

Diameter (in) |

Elongation |

| Monocord | ||||

| 1000/1 Poly | 20 | 4400 | 0.0100 | 13% |

| 1300/1 Poly | 24 | 3400 | 0.0110 | 13% |

| 1500/1 Poly | 30 | 2800 | 0.0145 | 13% |

| Cabled | ||||

| 1000/1/2 Poly | 35 | 2070 | 0.0235 | 20% |

| 1000/1/4 Poly | 70 | 1035 | 0.0315 | 20% |

* variety of Other fibers and constructions available upon request

Aramid Ripcords

| Common Aramid Ripcord Constructions | Strength (lbs) |

Yield (yds/lb) |

Diameter (in) |

Elongation |

| Monocord | ||||

| 1000/1 Aramid | 50 | 4400 | 0.0100 | 3-4% |

| 1500/1 Aramid | 72 | 2800 | 0.0145 | 3-4% |

| Cabled | ||||

| 1000/1/2 Aramid | 90 | 2070 | 0.0235 | 4-5% |

| 1000/1/3 Aramid | 140 | 1380 | 0.0300 | 4-5% |

| 1500/1/2 Aramid | 140 | 1380 | 0.0315 | 4-5% |

| 1500/1/3 Aramid | 200 | 935 | 0.0355 | 4-5% |

* variety of Other fibers and constructions available upon request

Dependable binder yarn cobbs

With the many different types of binders and braider equipment used in wire and cable manufacturing, Service Thread offers diverse packaging options to support them all. Contact us for the best material type, construction and package size for your application. Here is a quick run down on some popular material constructions.

Binders

| Common Binders |

Strength (lbs) |

Yield (yds/lb) |

Diameter (in) |

Elongation |

| Polyester | ||||

| 840/1 | 16 | 5300 | 0.0080 | 13% |

| 1000/1 | 20 | 4400 | 0.0100 | 13% |

| 1300/1 | 24 | 2800 | 0.0110 | 13% |

| Nylon | ||||

| 5040 Nylon | 94 | 860 | 0.0235 | 20% |

| Para-Aramid | ||||

| 1000/1 Para-Aramid | 50 | 4400 | 0.0100 | 3-4% |

| 1500/1 Para-Aramid | 72 | 2800 | 0.0145 | 3-4% |

*Other fibers and constructions available upon request

Waxed lacing cords, designed with your feedback

We designed our lacing cords with feedback from our customers for superior knot retention and ease of use. Our waxed lacing cords are made in the USA and ready for same-day shipment.

WAXED Poly LACING CORDS

| Popular Waxed Polyester Lacing Cords | Strength(lbs) | Yield (yds/lb) | Diameter (in) | Package Sizes |

| P1000/4 | 75 | 810 | 0.0340 | 8oz, 1 lb |

| P1000/1/4 | 75 | 800 | 0.0360 | 8oz, 1 lb |

| P1000/9 | 160 | 380 | 0.0500 | 8oz, 1 lb |

| P1000/1/9 | 160 | 355 | 0.0530 | 8oz, 1 lb |

| P1000/12 | 215 | 280 | 0.0600 | 8oz, 1 lb |

Services and solutions - fast

We customize products and services to fit your needs. We’ll shorten your lead times and help you improve efficiency. Reach out to us for technical assistance and scientific explanations.