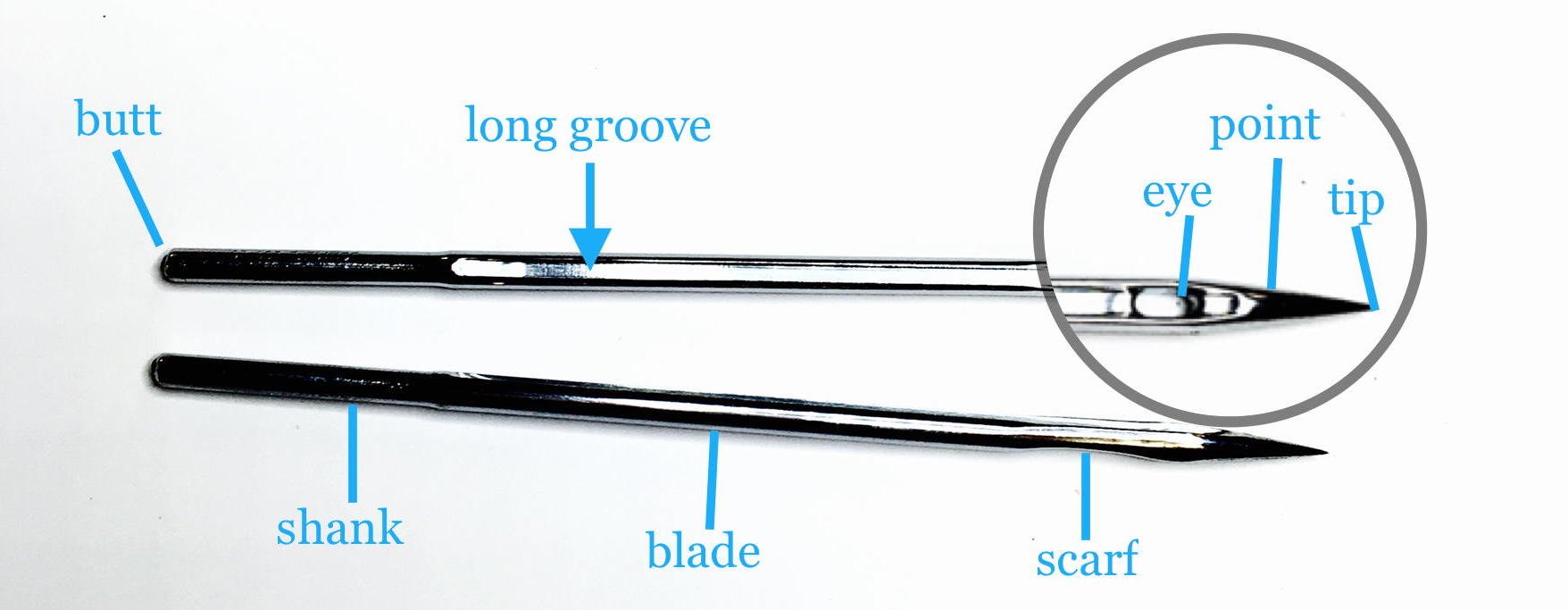

If your top thread is shredding or coming apart while sewing, this could indicate a common issue with the process. When the sewing machine pushes the needle through the material, it grabs the thread with a hook (or “looper”), while the needle rises back up. If there is a problem with this step it causes the thread to peel back, shred, break, flake, or not even get caught at all.

Read more- By Steve Zande

- 02/19/16

- 5 Comments

There are currently over thirty different bobbin styles that are used with sewing machines. (The size of the bobbin is known as the bobbin's style.) Every sewing machine is designed to be used with a specific style of bobbin. Many know how bobbins aid in sewing, but don't know or understand their various styles and uses. Some of the most common bobbin styles used for industrial sewing are listed below.

Read more

- By Steve Zande

- 01/29/16

- 1 Comment

Ripcords are industrial yarns located longitudinally just under the jackets that cover conductor wires in cables.

The purpose of a ripcord is to cut back the jacket to expose the wires of the cable so you don't run the risk of cutting any of the wires inside (you pull the cord, it cuts the jacket). This helps make splicing cables easier during installations.

Read more- By Steve Zande

- 01/08/16

- 2 Comments

Choosing the correct thread size for the specific applications is important in the yarn and thread industry, where thread size is the primary consideration for meeting the requirements of the finished product.

Read more- By Dane Hatcher

- 12/18/15

- 16 Comments

Until the 1940s, there were no standardized size designations for home or industrial needles; each manufacturer chose the sizing system they liked best and there were over 40 systems of sizing in use.

Read more- By Eric Shippee

- 12/11/15

- 0 Comments

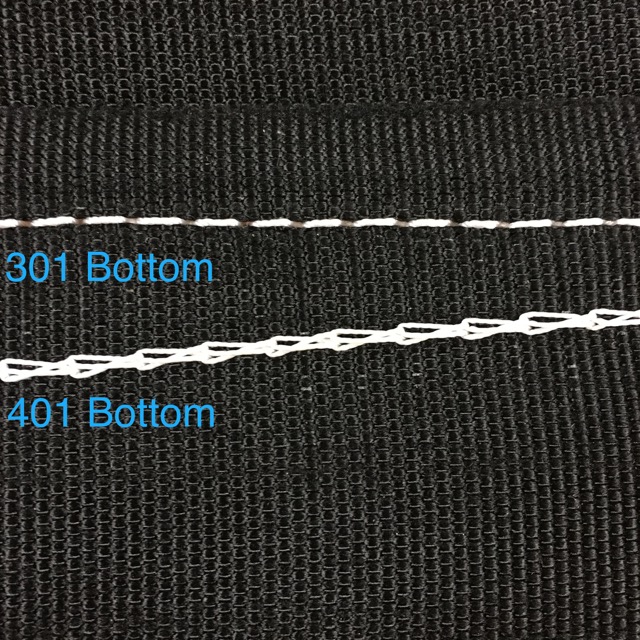

If you struggle with your materials falling apart at the seams — and you know the problem is with your thread instead of the fabric — you may have an issue with your seam strength or durability. This can be affected by your thread's fiber type, size, finish, or construction. Because all of these factors can affect your seam strength, it is important to use high-quality threads for all of your materials.

Read more- By Steve Zande

- 12/04/15

- 0 Comments

Many products use components created in places other than the final assembly site. Each component must itself conform to safety standards. The logic here is that if something is composed of parts that each pass safety tests, the final product will be safety compliant. A mattress is such a product, and its materials must be fire resistant so that the product sold to consumers can be deemed safe.

Read more- By Steve Zande

- 11/20/15

- 2 Comments

When a manufacturer is seeking a synthetic fiber that addresses heat and flame resistance, or one that demands extreme tensile strength, two materials immediately come to mind, the commercially branded Dupont™ Nomex® and Kevlar® composite materials. Each of these belong to the class of aramid fibers with the general characteristics which include a high melting point, a high strength to weight ratio and low elongation at break. These composite materials were developed by Dupont™ labs in the sixties and although Nomex® and Kevlar® are similar, they belong in different 'aromatic polyamide' classes, that is the meta-aramid and para-aramid fibers, respectively.

- By Steve Zande

- 11/12/15

- 5 Comments

Plastic fibers have found their place in the modern world by their many applications. Polypropylene and polyester are two families of plastics that are common for people to use day-to-day. For industrial uses, polypropylene and polyester have very different characteristics that make them suitable for different environmental stresses including sunlight exposure. Understanding the differences in UV resistance between polypropylene and polyester can help you decide the best yarn or thread for your application.

Read moreIf your top thread is shredding or coming apart while sewing, this could indicate a common issue with the process. When the sewing machine pushes the needle through the material, it grabs the thread with a hook (or “looper”), while the needle rises back up. If there is a problem with this step it causes the thread to peel back, shred, break, flake, or not even get caught at all.

Read moreThere are currently over thirty different bobbin styles that are used with sewing machines. (The size of the bobbin is known as the bobbin's style.) Every sewing machine is designed to be used with a specific style of bobbin. Many know how bobbins aid in sewing, but don't know or understand their various styles and uses. Some of the most common bobbin styles used for industrial sewing are listed below.

Read more

Ripcords are industrial yarns located longitudinally just under the jackets that cover conductor wires in cables.

The purpose of a ripcord is to cut back the jacket to expose the wires of the cable so you don't run the risk of cutting any of the wires inside (you pull the cord, it cuts the jacket). This helps make splicing cables easier during installations.

Read moreChoosing the correct thread size for the specific applications is important in the yarn and thread industry, where thread size is the primary consideration for meeting the requirements of the finished product.

Read moreUntil the 1940s, there were no standardized size designations for home or industrial needles; each manufacturer chose the sizing system they liked best and there were over 40 systems of sizing in use.

Read moreEasy Way to Estimate Sewing Seam Strength- Industrial Applications

- By Eric Shippee

- 12/11/15

- 0 Comments

If you struggle with your materials falling apart at the seams — and you know the problem is with your thread instead of the fabric — you may have an issue with your seam strength or durability. This can be affected by your thread's fiber type, size, finish, or construction. Because all of these factors can affect your seam strength, it is important to use high-quality threads for all of your materials.

Read moreASTM D7016 - Importance of fire retardant sewing thread in mattresses

- By Steve Zande

- 12/04/15

- 0 Comments

Many products use components created in places other than the final assembly site. Each component must itself conform to safety standards. The logic here is that if something is composed of parts that each pass safety tests, the final product will be safety compliant. A mattress is such a product, and its materials must be fire resistant so that the product sold to consumers can be deemed safe.

Read moreWhat Are The Differences Between Meta-Aramid And Para-Aramid yarns?

- By Steve Zande

- 11/20/15

- 2 Comments

When a manufacturer is seeking a synthetic fiber that addresses heat and flame resistance, or one that demands extreme tensile strength, two materials immediately come to mind, the commercially branded Dupont™ Nomex® and Kevlar® composite materials. Each of these belong to the class of aramid fibers with the general characteristics which include a high melting point, a high strength to weight ratio and low elongation at break. These composite materials were developed by Dupont™ labs in the sixties and although Nomex® and Kevlar® are similar, they belong in different 'aromatic polyamide' classes, that is the meta-aramid and para-aramid fibers, respectively.

Plastic fibers have found their place in the modern world by their many applications. Polypropylene and polyester are two families of plastics that are common for people to use day-to-day. For industrial uses, polypropylene and polyester have very different characteristics that make them suitable for different environmental stresses including sunlight exposure. Understanding the differences in UV resistance between polypropylene and polyester can help you decide the best yarn or thread for your application.

Read more