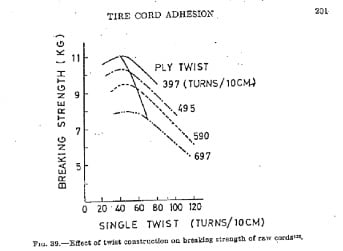

Spending years in materials science in the tire and rubber industry, I have found large volumes of publications available on most performance aspect of cord properties (strength, elasticity, fatigue, adhesion), and when I run across something on twist I usually make a note of it. I have seen less published data and information available on the effect of twist level on textile cord properties. I have collected a few “rules of thumb” from Takeyama and Fujimoto. Recently at Hailide America Inc, we have looked at the twist effects in an industrial-grade high-tenacity polyester and have found the old tire-cord-twist rules of thumb that apply are actually inverted in the low twist region.

Read more- By Eric Shippee

- 10/09/15

- 0 Comments

If you manufacture hoses, cables, or sewn products, yarn diameter or gauge is an important factor in determining what industrial yarn or thread type and construction to use. Not to be confused with the linear density or size of the material, yarn gauge is the measured thickness of a cross section of material.

Read more- By Eric Shippee

- 10/02/15

- 1 Comment

Control of static and current electricity is a crucial consideration in industrial product design. By using combinations of different polymers and coatings, industrial yarn and threads can be designed to help conduct or impede electrical charges as required for different product applications.

Read more- By Service Thread

- 09/25/15

- 4 Comments

Continuous filament polyester can be supplied in many forms but the most common for industrial applications are partially orientated yarn (POY) and fully orientated yarn (FOY).

Read more- By Service Thread

- 09/11/15

- 3 Comments

Modern nylon and polyester filament yarns share some similarities that may allow for cost reductions through materials engineering where polyester replaces nylon. However, there are some key differences to consider when designing an industrial sewing thread, hose reinforcement yarn, or textile binder or strength member. How are these fibers similar and how do they differ? The answers can be found in looking at the basic properties, and more importantly the end product application and environmental exposure to the fibers that will make all the difference in product success or failure,

Read more- By Steve Zande

- 09/04/15

- 0 Comments

Twist can impact the dynamics of your final product in many ways – strength, elongation, diameter, torque, lustre, softness etc. Unlike staple spun yarns, multifilament yarns lose strength as the twist is increased, therefore it is important to know the physical requirements required in the end product. Elongation increases with increasing twist, as does diameter, torque and lustre. Yarns become stiffer with twist therefore softness decreases.

Read more- By Dane Hatcher

- 08/28/15

- 9 Comments

Are skipped stitches causing you down time in your industrial sewing application? Here are some tips to help find and correct the common causes of skipped stitches.

- Check and make sure that machine is threaded correctly

- Make sure machine is oiled properly and general maintenance has been done

- Change the needle and make sure it is pushed all the way into the needle bar with the kerf/eye parallel to the hand wheel or slightly pointed towards incoming shuttle hook

- Check timing of needle in relation to hook. Make sure the needle is rising back up when checking the timing. When the tip of the hook is beside the needle, the eye of the needle should be ~ 1/16” below the hook. The tip of the hook should also be very close to the needle, about the thickness of printer paper from the needle:

- By Jay Todd

- 08/21/15

- 0 Comments

The Industrial Fabrics Association International (IFAI) is a trade assocation of member companies in specialty fabrics and advanced textiles with 1,491 members from 42 countries. Each year in October IFAI hosts the IFAI Expo, providing industrial textile companies and professionals with the opportunity to:

Read more- By Steve Zande

- 08/14/15

- 4 Comments

When setting out to find the best industrial high tenacity polyester, it's important to know and understand the key physical properties you are looking for, and to understand the units of measure being presented for each one. The table below contains a list of some of the largest polyester yarn producers in the world, as well as a list of polyester yarn specifications for specific types of their 1000 Dn (1100 dtex) high tenacity standard polyester yarns.

Read moreSpending years in materials science in the tire and rubber industry, I have found large volumes of publications available on most performance aspect of cord properties (strength, elasticity, fatigue, adhesion), and when I run across something on twist I usually make a note of it. I have seen less published data and information available on the effect of twist level on textile cord properties. I have collected a few “rules of thumb” from Takeyama and Fujimoto. Recently at Hailide America Inc, we have looked at the twist effects in an industrial-grade high-tenacity polyester and have found the old tire-cord-twist rules of thumb that apply are actually inverted in the low twist region.

Read moreIf you manufacture hoses, cables, or sewn products, yarn diameter or gauge is an important factor in determining what industrial yarn or thread type and construction to use. Not to be confused with the linear density or size of the material, yarn gauge is the measured thickness of a cross section of material.

Read moreConductive and Non Conductive Yarns

- By Eric Shippee

- 10/02/15

- 1 Comment

Control of static and current electricity is a crucial consideration in industrial product design. By using combinations of different polymers and coatings, industrial yarn and threads can be designed to help conduct or impede electrical charges as required for different product applications.

Read moreContinuous filament polyester can be supplied in many forms but the most common for industrial applications are partially orientated yarn (POY) and fully orientated yarn (FOY).

Read moreMaterials Science for Industrial Threads and Yarns - Polyester and Nylon

- By Service Thread

- 09/11/15

- 3 Comments

Modern nylon and polyester filament yarns share some similarities that may allow for cost reductions through materials engineering where polyester replaces nylon. However, there are some key differences to consider when designing an industrial sewing thread, hose reinforcement yarn, or textile binder or strength member. How are these fibers similar and how do they differ? The answers can be found in looking at the basic properties, and more importantly the end product application and environmental exposure to the fibers that will make all the difference in product success or failure,

Read moreTwist can impact the dynamics of your final product in many ways – strength, elongation, diameter, torque, lustre, softness etc. Unlike staple spun yarns, multifilament yarns lose strength as the twist is increased, therefore it is important to know the physical requirements required in the end product. Elongation increases with increasing twist, as does diameter, torque and lustre. Yarns become stiffer with twist therefore softness decreases.

Read moreIndustrial Sewing Troubleshooting Tips - Fixes for Skipped Stitches

- By Dane Hatcher

- 08/28/15

- 9 Comments

Are skipped stitches causing you down time in your industrial sewing application? Here are some tips to help find and correct the common causes of skipped stitches.

- Check and make sure that machine is threaded correctly

- Make sure machine is oiled properly and general maintenance has been done

- Change the needle and make sure it is pushed all the way into the needle bar with the kerf/eye parallel to the hand wheel or slightly pointed towards incoming shuttle hook

- Check timing of needle in relation to hook. Make sure the needle is rising back up when checking the timing. When the tip of the hook is beside the needle, the eye of the needle should be ~ 1/16” below the hook. The tip of the hook should also be very close to the needle, about the thickness of printer paper from the needle:

IFAI Expo 2015 Anaheim, California

- By Jay Todd

- 08/21/15

- 0 Comments

The Industrial Fabrics Association International (IFAI) is a trade assocation of member companies in specialty fabrics and advanced textiles with 1,491 members from 42 countries. Each year in October IFAI hosts the IFAI Expo, providing industrial textile companies and professionals with the opportunity to:

Read moreGeneral Specs: Best High Tenacity Polyester Yarn Suppliers Compared

- By Steve Zande

- 08/14/15

- 4 Comments

When setting out to find the best industrial high tenacity polyester, it's important to know and understand the key physical properties you are looking for, and to understand the units of measure being presented for each one. The table below contains a list of some of the largest polyester yarn producers in the world, as well as a list of polyester yarn specifications for specific types of their 1000 Dn (1100 dtex) high tenacity standard polyester yarns.

Read more