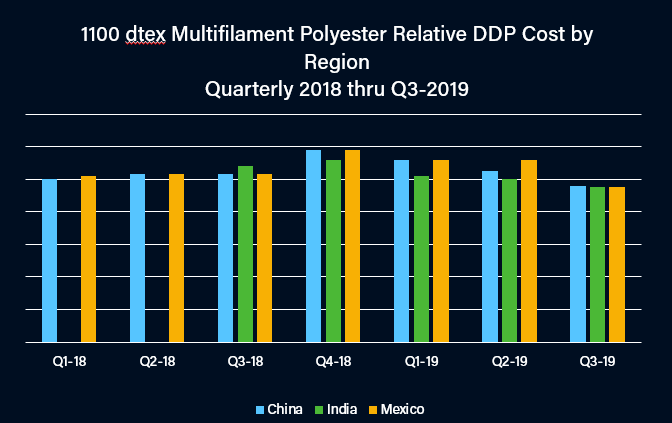

Unlike the September 2018 10 percent tariff, the additional 15 percent announced for shipments on or after May 10th may not have an immediate impact on the price of polyester yarn imports to the U.S.

Read more- By Steve Zande

- 05/01/19

- 0 Comments

Trade tensions between the E.U. and the U.S. have continued to escalate after a preliminary list of $11 billion in tariffs was announced in April 2019. In response to European subsidies to Airbus and a subsequent World Trade Organization (WTO) ruling, U.S. textile importers have faced a duty of up to 100% on certain materials.

Read more- By Steve Zande

- 04/23/19

- 1 Comment

In our previous article, What is Innegra™?, we looked at the basic properties of this relatively new fiber and some common uses for it. Now we’d like to share some tips for deciding whether it’s right for your purpose.

Read more- By Steve Zande

- 04/17/19

- 0 Comments

Are you familiar with Innegra™? It’s a new fiber on the market not yet well known among buyers and manufacturers of fiber products. But it has a wide variety of uses, from innovative aerospace materials to extreme sports equipment.

Read more- By Steve Zande

- 04/08/19

- 0 Comments

The Berry Amendment was passed in 1941 to promote the use of U.S.-sourced materials in military uses. It primarily covers tools, food, and textiles for use at home and abroad in military operations. The amendment outlines specific rules that govern how these goods are produced.

Read more- By Steve Zande

- 03/14/19

- 1 Comment

If you’ve come across the term Cotton Count and were a bit confused, you’re not alone. The terminology of the yarn and thread industry can be tricky.

Read more- By Eric Shippee

- 03/07/19

- 0 Comments

Tough and durable, UHMWPE (ultra-high-molecular-weight polyethylene) yarns have the highest tensile strength of any thermoplastic. You may also know these yarns by the names Spectra® and Dyneema®.

Read more- By Jay Todd

- 11/12/18

- 0 Comments

The Industrial Fabrics Foundation(IFF) has selected Service Thread for the 2018 Greater Good Award.

Read more- By Torry Losch

- 09/21/18

- 0 Comments

On September 17th the United States Trade Representative (USTR) Office announced additional tariffs of 10 percent on 5,745 items with an approximate value of $200 billion USD. As most of the world is aware, the Trump Administration and China are in a heated economic battle.

Read moreUnlike the September 2018 10 percent tariff, the additional 15 percent announced for shipments on or after May 10th may not have an immediate impact on the price of polyester yarn imports to the U.S.

Read moreWhat Do The Latest U.S. Trade Committee Hearings Mean for the Textile Industry?

- By Steve Zande

- 05/01/19

- 0 Comments

Trade tensions between the E.U. and the U.S. have continued to escalate after a preliminary list of $11 billion in tariffs was announced in April 2019. In response to European subsidies to Airbus and a subsequent World Trade Organization (WTO) ruling, U.S. textile importers have faced a duty of up to 100% on certain materials.

Read moreWhen to Choose Innegra™

- By Steve Zande

- 04/23/19

- 1 Comment

In our previous article, What is Innegra™?, we looked at the basic properties of this relatively new fiber and some common uses for it. Now we’d like to share some tips for deciding whether it’s right for your purpose.

Read moreWhat is Innegra™?

- By Steve Zande

- 04/17/19

- 0 Comments

Are you familiar with Innegra™? It’s a new fiber on the market not yet well known among buyers and manufacturers of fiber products. But it has a wide variety of uses, from innovative aerospace materials to extreme sports equipment.

Read moreUnderstanding the Berry Amendment and its Exceptions Related to Textiles and Sewing

- By Steve Zande

- 04/08/19

- 0 Comments

The Berry Amendment was passed in 1941 to promote the use of U.S.-sourced materials in military uses. It primarily covers tools, food, and textiles for use at home and abroad in military operations. The amendment outlines specific rules that govern how these goods are produced.

Read moreWhat is Cotton Count?

- By Steve Zande

- 03/14/19

- 1 Comment

If you’ve come across the term Cotton Count and were a bit confused, you’re not alone. The terminology of the yarn and thread industry can be tricky.

Read moreUHMWPE Suppliers and Types

- By Eric Shippee

- 03/07/19

- 0 Comments

Tough and durable, UHMWPE (ultra-high-molecular-weight polyethylene) yarns have the highest tensile strength of any thermoplastic. You may also know these yarns by the names Spectra® and Dyneema®.

Read moreThe Industrial Fabrics Foundation(IFF) has selected Service Thread for the 2018 Greater Good Award.

Read moreHow the Polyester Yarn Supply Chain is Impacted by the U.S. trade war with China

- By Torry Losch

- 09/21/18

- 0 Comments

On September 17th the United States Trade Representative (USTR) Office announced additional tariffs of 10 percent on 5,745 items with an approximate value of $200 billion USD. As most of the world is aware, the Trump Administration and China are in a heated economic battle.

Read more