Both Vectran™ and Aramid yarns are known for being resilient materials used for specialized products. They each have varying degrees of creep resistance, abrasion resistance, high tensile strength, excellent flex/fold characteristics, long term dimensional stability and exceptional property retention at high temperatures. These yarns are extremely durable and often used to protect people and products.

Read morePosts by Eric Shippee

- By Eric Shippee

- 10/27/17

- 0 Comments

- By Eric Shippee

- 09/07/17

- 0 Comments

When yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

Read more- By Eric Shippee

- 07/19/17

- 1 Comment

- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read more- By Eric Shippee

- 01/20/17

- 0 Comments

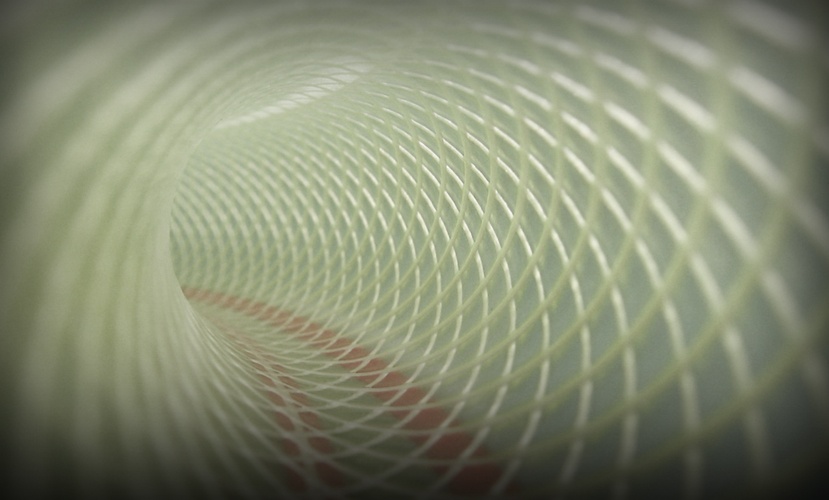

Over the past 20 years, more than 100 major sports facilities have opened in the United States to join the thousands already in operation. Throughout these sports complexes, concession stands see a great amount of traffic as fans enjoy stadium food and beverages during events. In particular, beverage hoses are a critical element in the sanitary dispensing of soda, beer and more.

Read more- By Eric Shippee

- 11/18/16

- 0 Comments

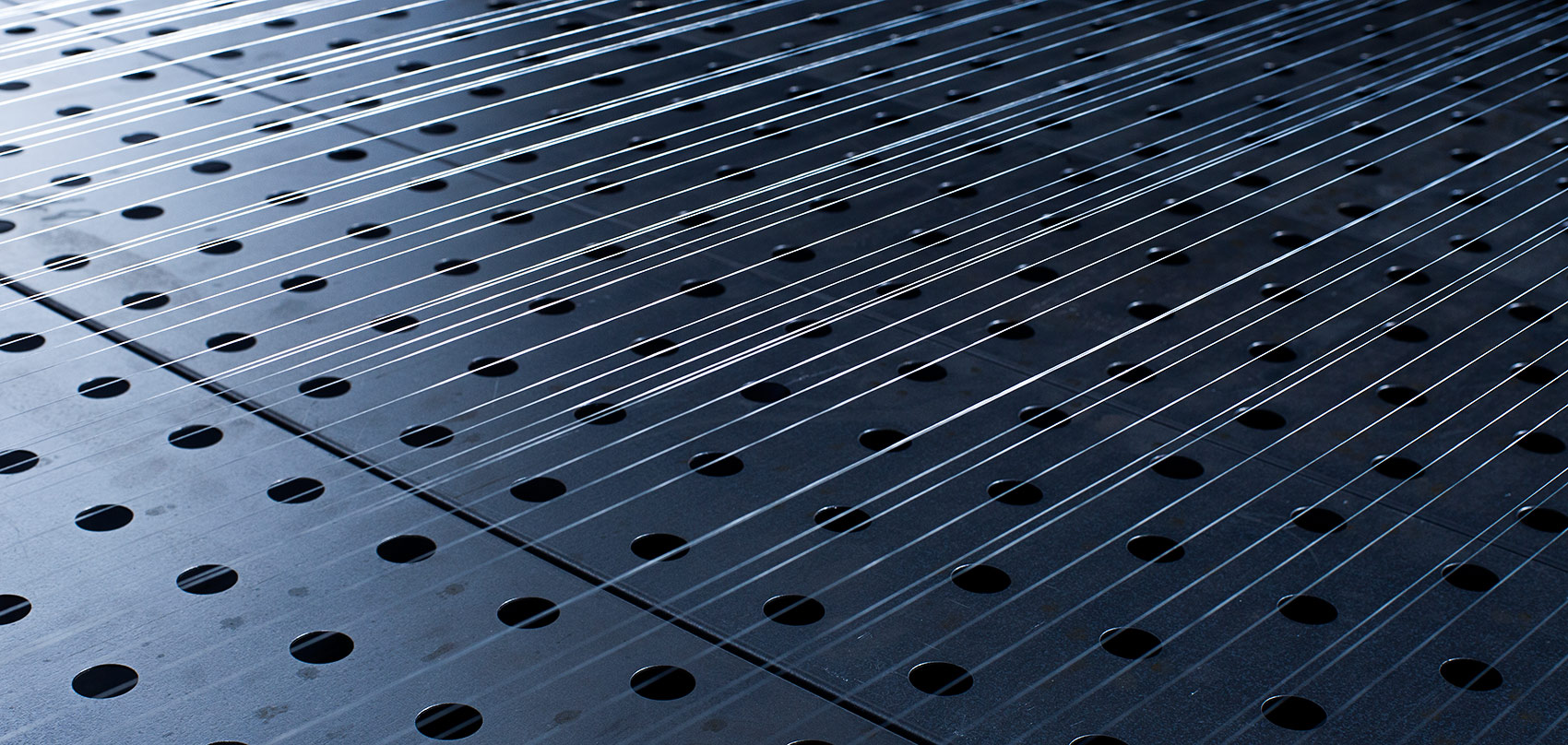

The critical reason for using waterblocking fiber in wire and cable manufacturing is to prevent access and dissipation of water and moisture throughout the cable. In fact, water is the most likely cause of premature failure for cable and electrical equipment. There are two common ways water and moisture finds its way into a cable:

Read more- By Eric Shippee

- 10/25/16

- 0 Comments

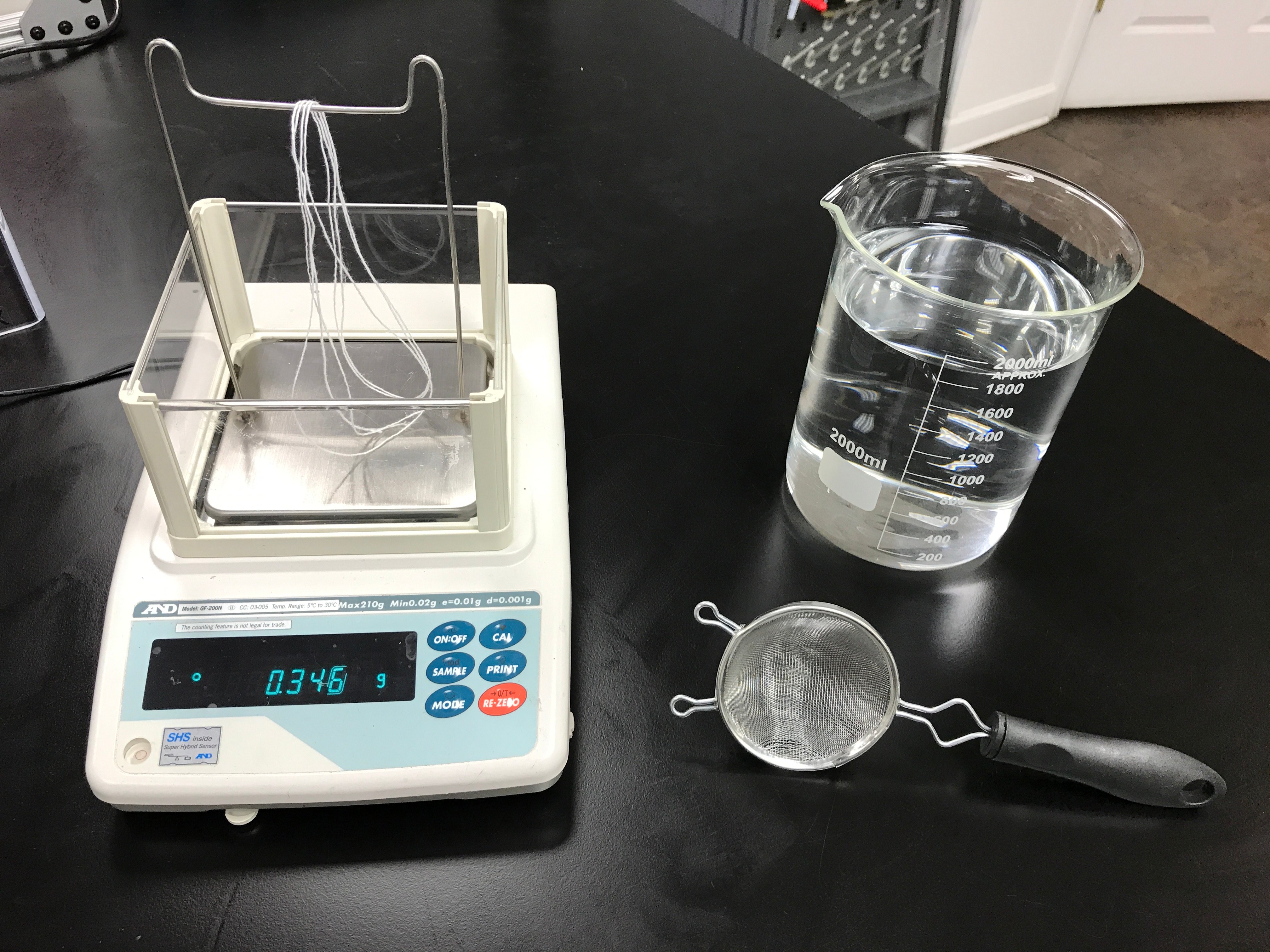

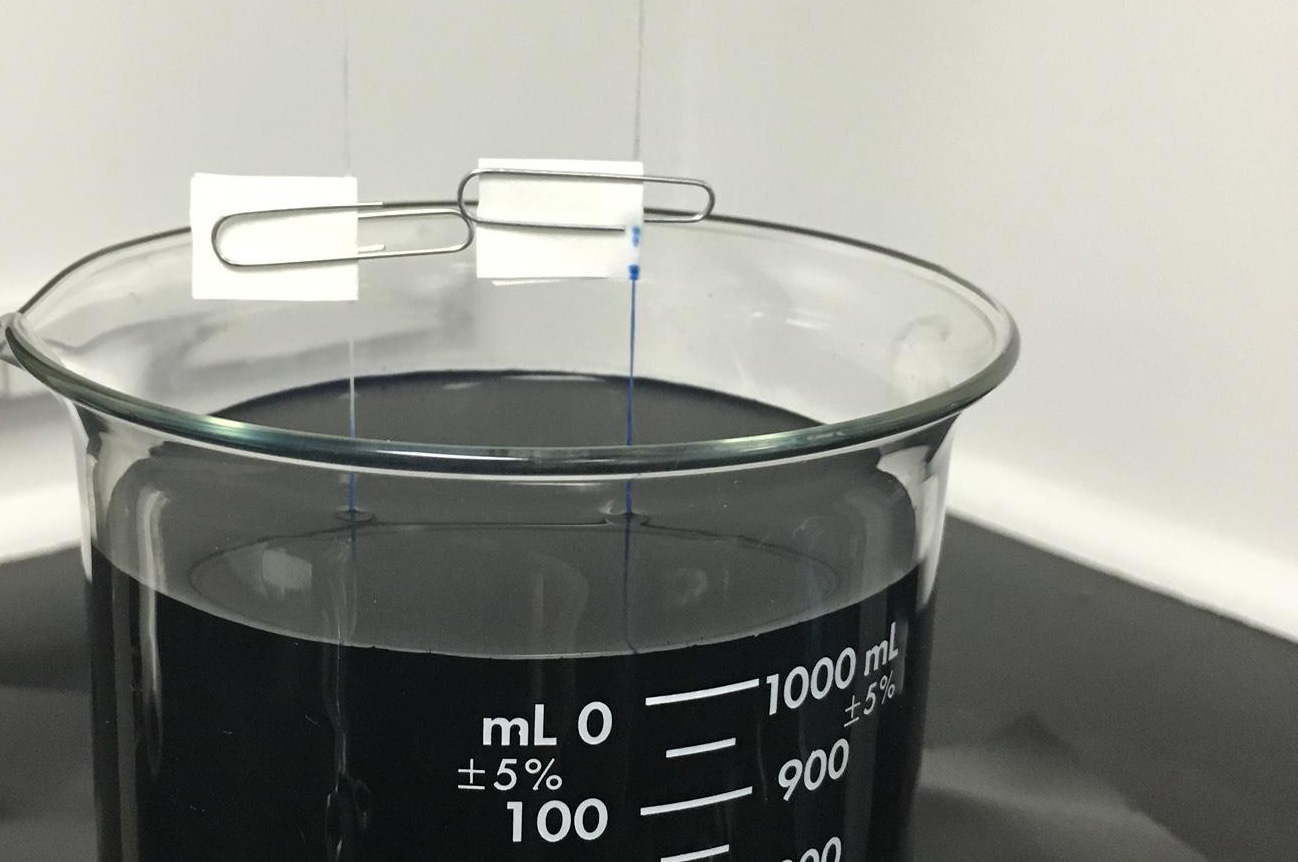

Manufacturers of wire and cable understand the importance of preventing moisture from making contact with fiber optics. Conducting a water wicking test for yarn and thread used in the manufacturing process can help with product evaluation, as well as save time and money in the long term.

Read more- By Eric Shippee

- 07/29/16

- 2 Comments

PTFE (polytetrafluoroethylene) is a thermoplastic polymer with a very low coefficient of friction along with excellent chemical, temperature, and environmental resistant properties. Commonly known by its brand names of Teflon™ , Yeumiflon® , or Profilen® , PTFE can be manufactured as a specialty fiber or thread for a broad range of applications including filtration, outdoor fabrics, electrical cables, and protective garments.

Read more

- By Eric Shippee

- 06/03/16

- 0 Comments

PVA, or Polyvinyl Alcohol, is a water-soluble synthetic polymer that lends itself to a variety of adaptions. PVA can be made into threads of fibers, liquids, coatings, beads, lubricants, and many other forms. As a filament yarn, PVA has valuable properties:

Read moreEric Shippee

Recent Posts

Vectran™ Vs. Aramid

- By Eric Shippee

- 10/27/17

- 0 Comments

Both Vectran™ and Aramid yarns are known for being resilient materials used for specialized products. They each have varying degrees of creep resistance, abrasion resistance, high tensile strength, excellent flex/fold characteristics, long term dimensional stability and exceptional property retention at high temperatures. These yarns are extremely durable and often used to protect people and products.

Read moreWhen yarn used in a wire and cable application prevents access of water and moisture to the critical elements - it is considered to be waterblocking. This feature is also known as water swellable or water absorbent. There are also various treatments that can be applied to a yarn to enhance its waterblocking characteristics. The most important function is that the yarn absorbs or blocks water in a way that stops water from causing damage to your product.

Read moreWhat is ASTM D4974? Hot Air Shrinkage Test for Yarn & Cord Explained

- By Eric Shippee

- 05/17/17

- 0 Comments

Synthetic yarns like nylon and polyester are typically known for their high shrinkage rate. In order to permanently set the physical properties of these materials after extrusion, they are stretched or drawn at elevated temperatures under tension during the manufacturing process, also known as heat setting. When stretched under these elevated temperatures, changes in physical properties happen and the crystallinity of these synthetic yarns is modified. The general physical properties of the thread or yarn can be adjusted by selecting the specific conditions under which the yarn is drawn, bringing the desired property changes to the material. Heat setting also stabilizes the yarn for future exposure to heat.

Read more5 Reasons to Use Industrial Yarn as Reinforcement in Beverage Hoses

- By Eric Shippee

- 01/20/17

- 0 Comments

Over the past 20 years, more than 100 major sports facilities have opened in the United States to join the thousands already in operation. Throughout these sports complexes, concession stands see a great amount of traffic as fans enjoy stadium food and beverages during events. In particular, beverage hoses are a critical element in the sanitary dispensing of soda, beer and more.

Read moreThe critical reason for using waterblocking fiber in wire and cable manufacturing is to prevent access and dissipation of water and moisture throughout the cable. In fact, water is the most likely cause of premature failure for cable and electrical equipment. There are two common ways water and moisture finds its way into a cable:

Read moreHow to Test Non-Wicking Properties of Yarns and Fibers for Wire and Cable

- By Eric Shippee

- 10/25/16

- 0 Comments

Manufacturers of wire and cable understand the importance of preventing moisture from making contact with fiber optics. Conducting a water wicking test for yarn and thread used in the manufacturing process can help with product evaluation, as well as save time and money in the long term.

Read morePTFE (polytetrafluoroethylene) is a thermoplastic polymer with a very low coefficient of friction along with excellent chemical, temperature, and environmental resistant properties. Commonly known by its brand names of Teflon™ , Yeumiflon® , or Profilen® , PTFE can be manufactured as a specialty fiber or thread for a broad range of applications including filtration, outdoor fabrics, electrical cables, and protective garments.

Read more

PVA, or Polyvinyl Alcohol, is a water-soluble synthetic polymer that lends itself to a variety of adaptions. PVA can be made into threads of fibers, liquids, coatings, beads, lubricants, and many other forms. As a filament yarn, PVA has valuable properties:

Read more