Modulus (fiber elasticity) is a key characteristic of industrial yarn and thread for wire and cable - specifically aramid yarns. Modulus refers to the ratio of stress (force per unit area) along an axis to strain (ratio of deformation over initial length) along that axis. Think about when you stretch a rubber band out to the point right before it deforms or breaks – that is the modulus. When something stretches to the point of deformation, the strength is almost always compromised.

Read more- By Eric Shippee

- 11/18/16

- 0 Comments

The critical reason for using waterblocking fiber in wire and cable manufacturing is to prevent access and dissipation of water and moisture throughout the cable. In fact, water is the most likely cause of premature failure for cable and electrical equipment. There are two common ways water and moisture finds its way into a cable:

Read more- By Eric Shippee

- 10/25/16

- 0 Comments

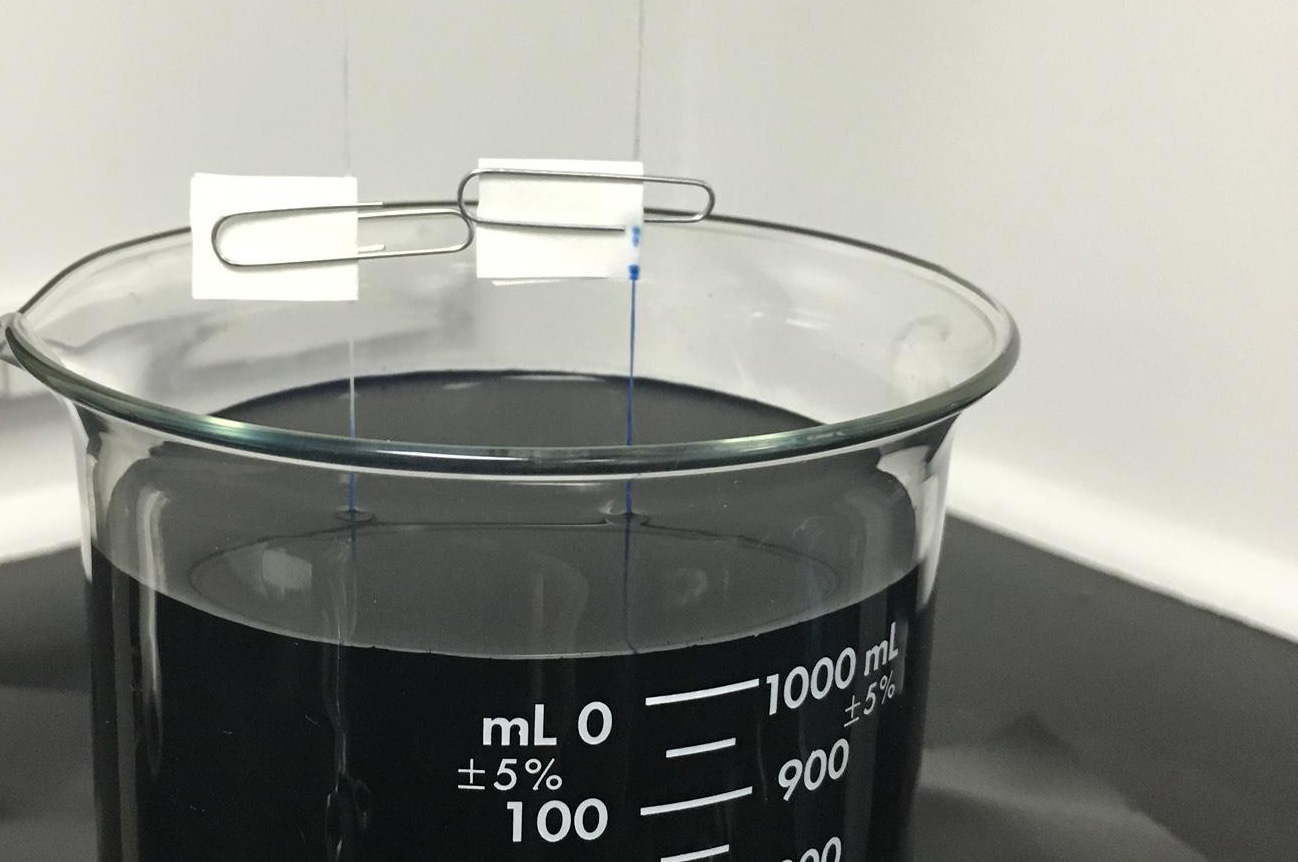

Manufacturers of wire and cable understand the importance of preventing moisture from making contact with fiber optics. Conducting a water wicking test for yarn and thread used in the manufacturing process can help with product evaluation, as well as save time and money in the long term.

Read more- By Steve Zande

- 01/29/16

- 1 Comment

Ripcords are industrial yarns located longitudinally just under the jackets that cover conductor wires in cables.

The purpose of a ripcord is to cut back the jacket to expose the wires of the cable so you don't run the risk of cutting any of the wires inside (you pull the cord, it cuts the jacket). This helps make splicing cables easier during installations.

Read more- By Christine Domer

- 10/23/15

- 0 Comments

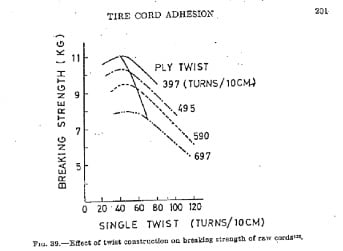

Spending years in materials science in the tire and rubber industry, I have found large volumes of publications available on most performance aspect of cord properties (strength, elasticity, fatigue, adhesion), and when I run across something on twist I usually make a note of it. I have seen less published data and information available on the effect of twist level on textile cord properties. I have collected a few “rules of thumb” from Takeyama and Fujimoto. Recently at Hailide America Inc, we have looked at the twist effects in an industrial-grade high-tenacity polyester and have found the old tire-cord-twist rules of thumb that apply are actually inverted in the low twist region.

Read more- By Eric Shippee

- 10/09/15

- 0 Comments

If you manufacture hoses, cables, or sewn products, yarn diameter or gauge is an important factor in determining what industrial yarn or thread type and construction to use. Not to be confused with the linear density or size of the material, yarn gauge is the measured thickness of a cross section of material.

Read more- By Eric Shippee

- 10/02/15

- 1 Comment

Control of static and current electricity is a crucial consideration in industrial product design. By using combinations of different polymers and coatings, industrial yarn and threads can be designed to help conduct or impede electrical charges as required for different product applications.

Read more- By Steve Zande

- 09/04/15

- 0 Comments

Twist can impact the dynamics of your final product in many ways – strength, elongation, diameter, torque, lustre, softness etc. Unlike staple spun yarns, multifilament yarns lose strength as the twist is increased, therefore it is important to know the physical requirements required in the end product. Elongation increases with increasing twist, as does diameter, torque and lustre. Yarns become stiffer with twist therefore softness decreases.

Read more- By Steve Zande

- 08/14/15

- 4 Comments

When setting out to find the best industrial high tenacity polyester, it's important to know and understand the key physical properties you are looking for, and to understand the units of measure being presented for each one. The table below contains a list of some of the largest polyester yarn producers in the world, as well as a list of polyester yarn specifications for specific types of their 1000 Dn (1100 dtex) high tenacity standard polyester yarns.

Read moreModulus (fiber elasticity) is a key characteristic of industrial yarn and thread for wire and cable - specifically aramid yarns. Modulus refers to the ratio of stress (force per unit area) along an axis to strain (ratio of deformation over initial length) along that axis. Think about when you stretch a rubber band out to the point right before it deforms or breaks – that is the modulus. When something stretches to the point of deformation, the strength is almost always compromised.

Read moreThe critical reason for using waterblocking fiber in wire and cable manufacturing is to prevent access and dissipation of water and moisture throughout the cable. In fact, water is the most likely cause of premature failure for cable and electrical equipment. There are two common ways water and moisture finds its way into a cable:

Read moreHow to Test Non-Wicking Properties of Yarns and Fibers for Wire and Cable

- By Eric Shippee

- 10/25/16

- 0 Comments

Manufacturers of wire and cable understand the importance of preventing moisture from making contact with fiber optics. Conducting a water wicking test for yarn and thread used in the manufacturing process can help with product evaluation, as well as save time and money in the long term.

Read moreRipcords are industrial yarns located longitudinally just under the jackets that cover conductor wires in cables.

The purpose of a ripcord is to cut back the jacket to expose the wires of the cable so you don't run the risk of cutting any of the wires inside (you pull the cord, it cuts the jacket). This helps make splicing cables easier during installations.

Read moreSpending years in materials science in the tire and rubber industry, I have found large volumes of publications available on most performance aspect of cord properties (strength, elasticity, fatigue, adhesion), and when I run across something on twist I usually make a note of it. I have seen less published data and information available on the effect of twist level on textile cord properties. I have collected a few “rules of thumb” from Takeyama and Fujimoto. Recently at Hailide America Inc, we have looked at the twist effects in an industrial-grade high-tenacity polyester and have found the old tire-cord-twist rules of thumb that apply are actually inverted in the low twist region.

Read moreIf you manufacture hoses, cables, or sewn products, yarn diameter or gauge is an important factor in determining what industrial yarn or thread type and construction to use. Not to be confused with the linear density or size of the material, yarn gauge is the measured thickness of a cross section of material.

Read moreConductive and Non Conductive Yarns

- By Eric Shippee

- 10/02/15

- 1 Comment

Control of static and current electricity is a crucial consideration in industrial product design. By using combinations of different polymers and coatings, industrial yarn and threads can be designed to help conduct or impede electrical charges as required for different product applications.

Read moreTwist can impact the dynamics of your final product in many ways – strength, elongation, diameter, torque, lustre, softness etc. Unlike staple spun yarns, multifilament yarns lose strength as the twist is increased, therefore it is important to know the physical requirements required in the end product. Elongation increases with increasing twist, as does diameter, torque and lustre. Yarns become stiffer with twist therefore softness decreases.

Read moreGeneral Specs: Best High Tenacity Polyester Yarn Suppliers Compared

- By Steve Zande

- 08/14/15

- 4 Comments

When setting out to find the best industrial high tenacity polyester, it's important to know and understand the key physical properties you are looking for, and to understand the units of measure being presented for each one. The table below contains a list of some of the largest polyester yarn producers in the world, as well as a list of polyester yarn specifications for specific types of their 1000 Dn (1100 dtex) high tenacity standard polyester yarns.

Read more