A creel is simply a frame on which the feeding thread or yarn bobbin is fitted. Often, the creel is fitted with a yarn tensioning device which controls tension variation. Proper placement and stabilization of thread and yarn at the beginning of the product manufacturing process is critical. “Think of a creel as the foundation of a building,” states Neal Fournier, Facilities & Maintenance Manager with Service Thread. “It’s likely that process improvement starts after the yarn enters the production process; however, you will be surprised by the gains that can be made by taking a look at using a creel or refining your creel design.”

Read more- By Eric Shippee

- 01/26/18

- 0 Comments

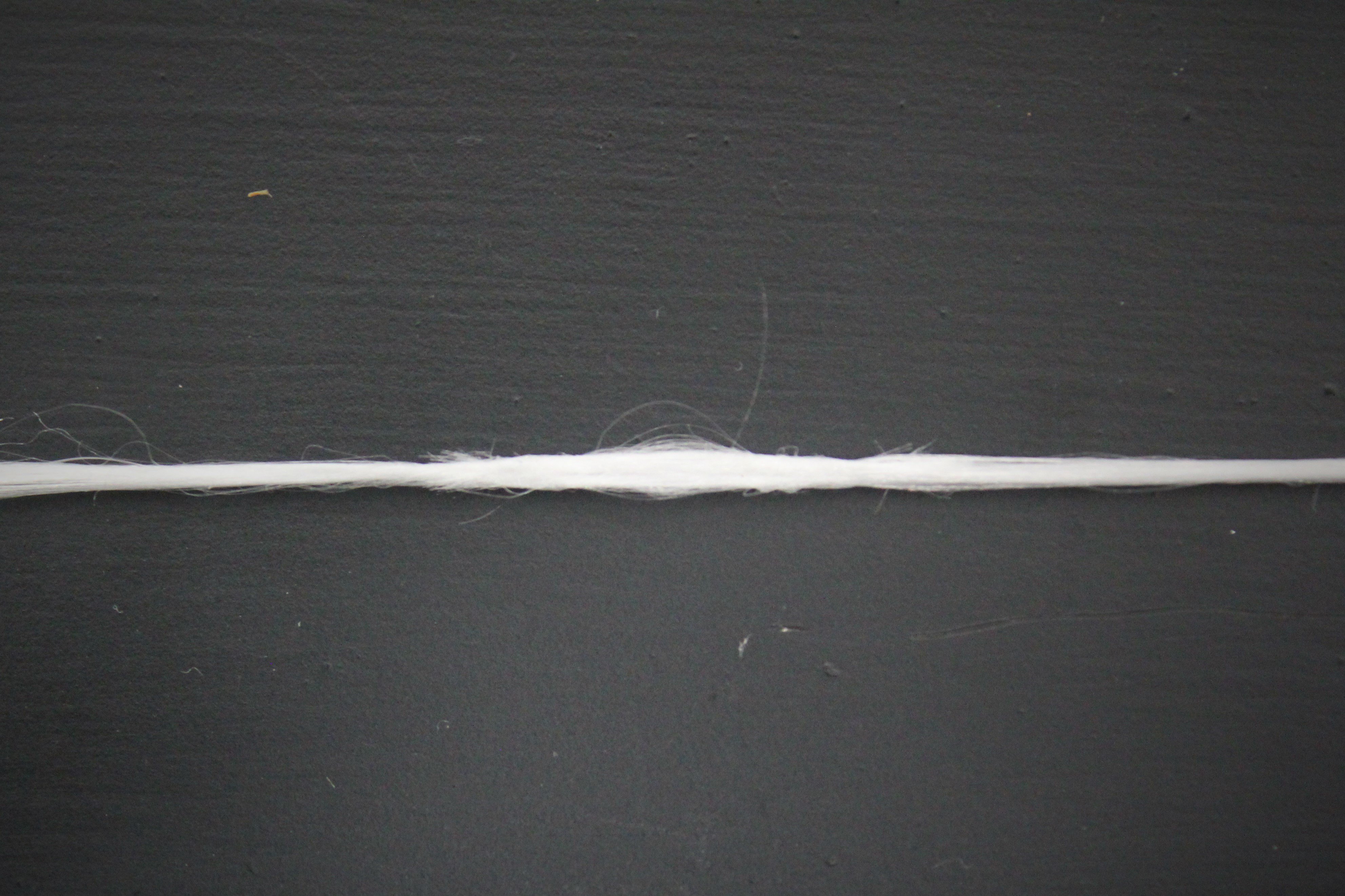

The practice of joining industrial yarn ends (resulting from breaks, defects, or end of the supply), is a critical component to the product manufacturing process, particularly in industries such as wire and cable (integration of ripcords), hose reinforcement, belting and more. When using industrial yarn in the production process, it is essential that the joining method endures the process without interruption and does not have a negative effect on the quality of the end product.

Read more- By Steve Zande

- 11/12/15

- 5 Comments

Plastic fibers have found their place in the modern world by their many applications. Polypropylene and polyester are two families of plastics that are common for people to use day-to-day. For industrial uses, polypropylene and polyester have very different characteristics that make them suitable for different environmental stresses including sunlight exposure. Understanding the differences in UV resistance between polypropylene and polyester can help you decide the best yarn or thread for your application.

Read more- By Dane Hatcher

- 08/28/15

- 9 Comments

Are skipped stitches causing you down time in your industrial sewing application? Here are some tips to help find and correct the common causes of skipped stitches.

- Check and make sure that machine is threaded correctly

- Make sure machine is oiled properly and general maintenance has been done

- Change the needle and make sure it is pushed all the way into the needle bar with the kerf/eye parallel to the hand wheel or slightly pointed towards incoming shuttle hook

- Check timing of needle in relation to hook. Make sure the needle is rising back up when checking the timing. When the tip of the hook is beside the needle, the eye of the needle should be ~ 1/16” below the hook. The tip of the hook should also be very close to the needle, about the thickness of printer paper from the needle:

- By Jay Todd

- 08/21/15

- 0 Comments

The Industrial Fabrics Association International (IFAI) is a trade assocation of member companies in specialty fabrics and advanced textiles with 1,491 members from 42 countries. Each year in October IFAI hosts the IFAI Expo, providing industrial textile companies and professionals with the opportunity to:

Read more- By Steve Zande

- 07/17/15

- 0 Comments

Multifilament nylons, polyesters and aramid yarns go through a series of twisting and winding steps during the sewing thread manufacturing process. The twisting process is generally required to convert any yarn into a thread that can be used for sewing, but bonding, an additional process step, may not be needed depending on the size, use and industrial application.

Read more

- By Jay Todd

- 05/06/14

- 2 Comments

We get questions every week from manufacturers who want to use one or more ends of a colored yarn or thread for product identification (marker threads) and for production marketing and differentiation. An understanding of the types of dyed yarns available, and the advantages and disadvantages of each is crucial to product performance and design.

Read more- By Jay Todd

- 04/14/14

- 2 Comments

Should you be using a polypropylene or polyester sewing thread? We compare these two different materials to help you decide.

Read more- By Eric Shippee

- 09/16/13

- 0 Comments

What if you could immediately improve the occurrences of thread breaks and skipped stitches in your sewing operations for between $1 to $3? Would you be interested?

Often overlooked, choosing the correct needle for your sewing application is absolutely critical to flawless performance of your sewing line. With the new thread and sewn fabric materials available today, it may be time to check the needle size for your operation

Read more- By Ken Massie

- 11/09/12

- 0 Comments

Have you ever experienced dropped stitches or thread breakage when closing bags? Don’t worry—I’ll share a few common red flags you can scan for quickly to ensure maximum production.

Read moreA creel is simply a frame on which the feeding thread or yarn bobbin is fitted. Often, the creel is fitted with a yarn tensioning device which controls tension variation. Proper placement and stabilization of thread and yarn at the beginning of the product manufacturing process is critical. “Think of a creel as the foundation of a building,” states Neal Fournier, Facilities & Maintenance Manager with Service Thread. “It’s likely that process improvement starts after the yarn enters the production process; however, you will be surprised by the gains that can be made by taking a look at using a creel or refining your creel design.”

Read moreOlder Posts

The practice of joining industrial yarn ends (resulting from breaks, defects, or end of the supply), is a critical component to the product manufacturing process, particularly in industries such as wire and cable (integration of ripcords), hose reinforcement, belting and more. When using industrial yarn in the production process, it is essential that the joining method endures the process without interruption and does not have a negative effect on the quality of the end product.

Read morePlastic fibers have found their place in the modern world by their many applications. Polypropylene and polyester are two families of plastics that are common for people to use day-to-day. For industrial uses, polypropylene and polyester have very different characteristics that make them suitable for different environmental stresses including sunlight exposure. Understanding the differences in UV resistance between polypropylene and polyester can help you decide the best yarn or thread for your application.

Read moreIndustrial Sewing Troubleshooting Tips - Fixes for Skipped Stitches

- By Dane Hatcher

- 08/28/15

- 9 Comments

Are skipped stitches causing you down time in your industrial sewing application? Here are some tips to help find and correct the common causes of skipped stitches.

- Check and make sure that machine is threaded correctly

- Make sure machine is oiled properly and general maintenance has been done

- Change the needle and make sure it is pushed all the way into the needle bar with the kerf/eye parallel to the hand wheel or slightly pointed towards incoming shuttle hook

- Check timing of needle in relation to hook. Make sure the needle is rising back up when checking the timing. When the tip of the hook is beside the needle, the eye of the needle should be ~ 1/16” below the hook. The tip of the hook should also be very close to the needle, about the thickness of printer paper from the needle:

IFAI Expo 2015 Anaheim, California

- By Jay Todd

- 08/21/15

- 0 Comments

The Industrial Fabrics Association International (IFAI) is a trade assocation of member companies in specialty fabrics and advanced textiles with 1,491 members from 42 countries. Each year in October IFAI hosts the IFAI Expo, providing industrial textile companies and professionals with the opportunity to:

Read moreMultifilament nylons, polyesters and aramid yarns go through a series of twisting and winding steps during the sewing thread manufacturing process. The twisting process is generally required to convert any yarn into a thread that can be used for sewing, but bonding, an additional process step, may not be needed depending on the size, use and industrial application.

Read more

We get questions every week from manufacturers who want to use one or more ends of a colored yarn or thread for product identification (marker threads) and for production marketing and differentiation. An understanding of the types of dyed yarns available, and the advantages and disadvantages of each is crucial to product performance and design.

Read more

Should you be using a polypropylene or polyester sewing thread? We compare these two different materials to help you decide.

Read more

What if you could immediately improve the occurrences of thread breaks and skipped stitches in your sewing operations for between $1 to $3? Would you be interested?

Often overlooked, choosing the correct needle for your sewing application is absolutely critical to flawless performance of your sewing line. With the new thread and sewn fabric materials available today, it may be time to check the needle size for your operation

Read moreTop Tips for Trouble-Free Bag Sewing

- By Ken Massie

- 11/09/12

- 0 Comments

Have you ever experienced dropped stitches or thread breakage when closing bags? Don’t worry—I’ll share a few common red flags you can scan for quickly to ensure maximum production.

Read more