There is nothing worse than trying to handle a yarn or thread that snarls and kinks up on you while trying to process it. I have always been a believer in quantifying conditions and therefore developed a method for measuring the amount of torque remaining in a yarn or thread, with the resulting units of measure being referred to as Twist Balance (TB).

What is Torque?

Torque: a twisting force that tends to cause rotation

When twist is applied to a yarn torque is created. With a thread, torque forces can be balanced by using opposite twist in the singles and ply twist. With a single yarn, required twist levels may create enough torque to require heat setting through a conditioning oven, autoclave or even dye bath to minimize torque forces. Excessive torque can cause yarn or thread to kink excessively/snarl or “French-knot”, resulting in processing problems including snags, needle breaks and skipped stitches.

How to Perform a Twist Balance (TB) test.

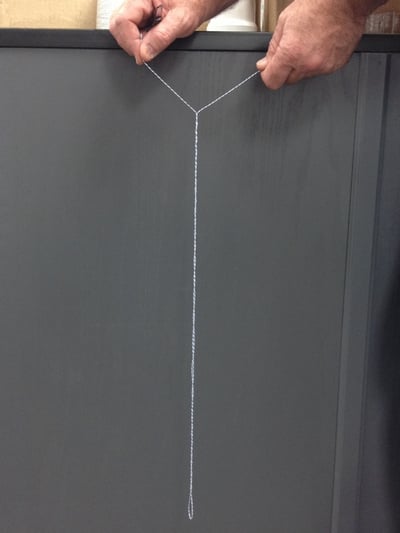

- Roll off (do not off wind over the nose, this can add or subtract twist) approx 36”, pinching both ends between fingers to prevent twist from shifting, and move pinch points to approx. 6” apart allowing thread to form a ‘U’.

- Allow any movement of the yarn and wait until it comes to a stop. If there is no movement and vertical portions of ‘U’ remain parallel, then Twist Balance = 0.

- If yarn twists upon itself, place two fingers through the final loop at the bottom of the “braid” and count the number of full 360° rotations it takes to get both ends back to parallel.

We find that a twist balance (TB) of five rotations or less works well for most applications. If the TB value is greater five, an additional processing step called conditioning or heat setting is recommended to reduce the torque.

Download our guide below for helpful tips on best practices and the latest processing tools available to help control yarn tension and other variables that can affect the application of binders, ripcord and strength member into your manufacturing process.