To understand twist contraction, think about a ship’s mooring rope. It’s a large, thick rope with thousands of yarns braided and twisted inside. Try to lift a section of the rope, and you’ll find it’s quite heavy.

If you unwound all of the internal threads of the mooring rope, each section would feel much lighter. The individual strands would also appear longer. But when it’s all wound together, the mooring rope becomes heavier and shorter. This is due to the effect of twist contraction.

What is Twist in Textiles?

Twist is simply the spiral arrangement of fibers around the axis of the yarn. Through twisting, the fibers are bound together and create a stronger yarn. The number of twists involved is normally referred to as turns per inch or turns per meter.

The amount of twist added to yarn defines its strength, and an optimal level of strength is sought through careful calculation. Twist also affects the look of the yarn, changing its appearance to be duller or brighter.

Many industries require twist in their materials for specific applications and purposes. Knowing this, Service Thread buys raw materials in flat form and applies varying levels of twist depending on what our customers need.

We can twist almost any type of fiber - polyester, nylon, aramid, cotton, and more. Twist also involves rope, braids, hoses, cords, and other applications. Let’s review some common uses that show the importance of twist.

Industry Applications

In the wire and cable industry, there is a high demand for ripcords which are used to open cable jackets. A ripcord must be able to rip through various jacket thicknesses and depending on the jacket, a twisted ripcord may be required. Depending on the construction of a ripcord, excessive twist can also create too much stiffness and torque which can cause issues when applying into the cable manufacturing process. A ripcord actually needs a bit of flex to rip through something else without breaking, so it’s important to use a ripcord with the right twist levels which can vary based on processing application and material requirements.

For sportswear fabrics and certain types of blankets, the feel of fabric guides the amount of twist. Weaving yarns typically have a higher twist level because most knitted products need a soft, warm, comfortable feel that comes from using something like a spun cotton yarn. It can take a high twist and remain soft.

To create materials with just the right characteristics, it is important to understand exactly how a product is being used and many times a simple formula help determine an optimal twist level. Below are some of the formulas involved, so you can understand how to factor twist into your production process.

The Twist Multiplier

The twist multiplier (TM) plays a large part in assigning the stiffness or “feel” of a yarn. It also affects strength, light refraction, and many other qualities. In general:

Low TM = softer yarn

High TM = stiffer yarn

The twist multiplier can be used to define the character of a yarn. Weaving yarns will typically have a higher TM. Continuous filament yarns require a lower TM to attain optimal strength. To understand why these things are true, let’s look at the equations used to help find the desired level of twist.

Twist (TPI) = TM x SQRT NeC, or

Twist (TPM) = TM / SQRT Tex

This leads us to our next factor related to twist, which is the amount of contraction that occurs from the process of twisting.

Understanding Twist Contraction

Remember our mooring rope that seemed to change length depending on whether it was wound or unwound? That was due to contraction. Twist contraction (TC) is how much something compacts when you twist it.

Twist contraction affects the length of the finished product - it affects your yield - because when the yarn is twisted two or three turns, you may end up with .95 meters instead of 1 meter. Knowing this, you can factor it in and always start out with the right amount and end with the right amount.

Here is the formula used to calculate the amount of twist contraction:

% TC = Length Before Twisting (A) – Length After Twisting (B) x 100%

Length Before Twisting (A)

Because of twist contraction and the associated change in length, the yarn size will change slightly when the twist in the yarn changes. Twist contraction increases yarn size because the weight of the yarn is distributed over a shorter length.

To find the denier after twisting, the following formula can be used:

Denier After Twisting = Denier Before Twisting

1 - % Contraction

Finding Optimal Twist for Your Process

As you can see, the math can really help when it comes to twist. If it is not the appropriate twist you can cause warping, breakage, kinking, and excessive liveliness (movement) in the production line. If the torque of the twist isn’t controlled, you may even need to apply heat stabilization for certain materials.

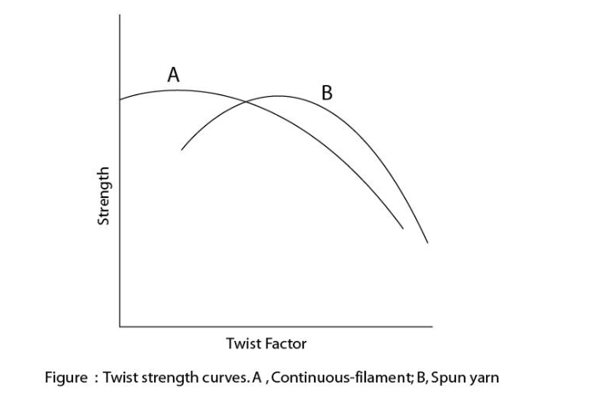

To help you control and account for twist, we have created the following figure that illustrates the point of optimal twist. As you look at the figure, consider the difference between continuous filaments and spun yarn.

With continuous filaments, if you over-twist them you’ll lose strength. However, spun yarns, to a point, get stronger when you continue to twist them. So that’s why the twist level is quite different for continuous filaments vs. spun yarn in the figure below.

Here’s the bottom line: The twist level should be matched to the application. Too much or too little twist, can cause problems on the production line or create an inferior finished product.

If you need assistance finding a product construction that is best for your industrial manufacturing application, turn to the experts at Service Thread. We’ve spent decades researching the factors that impact processing, and we’re always here as a resource for you.