Customers often ask for thread that meets Mil Specs. These specifications or standards are often used by other government organizations and industries, so it is important to understand the basics of the standard. Here’s a summary of MIL-DTL-32072 the United States Department of Defense product standard for multifilament polyester thread to be used in machine sewing. The standard outlines minimum product physical specifications and is divided into several sections in the 17 page standard.

Thread Types:

Polyester thread is designated as one of five types by MIL-DTL-32072. These types describe the basic construction of the thread, or how the thread is assembled or manufactured:

- Type I – Twisted soft multiple cord - twisted, multiple cord (ply) construction. This is cabled yarn or two step twisted yarn, not bonded, with a soft finish.

- Type II – Twisted bonded multiple cord - the same construction as type I, except that the type II thread is bonded.

- Type III – Bonded mono cord - a single ply, mono cord construction with a single twist of no more than five turns-per-inch (tpi). Type III thread is bonded to form a smooth even mono cord.

- Type IV – Soft air entangled - one or more yarns that are air entangled together by the manufacturing process to form a single ply thread with a final twist of no more than 10 tpi, not bonded with a soft finish.

- Type V – Bonded air entangled - the same construction as type IV except that the type V thread is bonded.

Classes:

There are two classes and three subclasses listed as part of the standard that address other properties of the thread – Classes describe elongation or shrinkage and Subclasses address thread finish:

- Class 1 – Normal Elongation – this is a maximum elongation percentage of 26 percent at break.

- Class 3 – Heat Stable – low shrinkage – this is an elongation at break between 15 to 35 percent.

Subclasses:

- Subclass A – General Purpose

- Subclass B – Non-wicking Finish

- Subclass C – No Finish

Additionally, there are government labeling requirements that designate the specification:

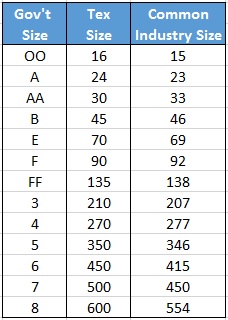

What does this all mean? Industry part numbers often contain portions of the Mil Spec standard. Here is an example of a polyester part number:

MIL-DTL-32072-II-1-3/C

Decoded, this is:

Standard – Type – Class – Gov’t Size/Subclass

So this product would be an industry item 207 Bonded Polyester cabled twisted yarn with normal elongation and no finish.

Using this information you can look for the parts of the standard in a part number to decode or interpret what a customer needs. Note: you might see the various parts of the standard (type, class, sizes) rearranged in different order from one company part number to another. Use the standard information and you can figure it out with a little work.

While the Mil Spec standard is useful to know, these standards, last updated in 1991, are fairly basic in regards to physical properties. Most thread manufacturers easily meet and in fact exceed the Mil Spec thread standards, and a quality manufacturer will typically have their own product standards that are more detailed, easier to understand, and better for ensuring quality thread performance.

So if you need Mil Spec threads or help in setting up a product specification, contact our technical group— we’re here to help.