One of our large industrial hose manufacturing customers had problems getting long lengths without yarn breaks or run outs in their Karg reinforcement yarn braiding department. Like most fluid hose manufacturers, they were using a combination of flanged bobbins wound in-house and cardboard prewound braider tubes to meet their production scheudule demands.

One of our large industrial hose manufacturing customers had problems getting long lengths without yarn breaks or run outs in their Karg reinforcement yarn braiding department. Like most fluid hose manufacturers, they were using a combination of flanged bobbins wound in-house and cardboard prewound braider tubes to meet their production scheudule demands.

The Karg braiders in use were designed to work best with flanged bobbins, but were capable of running the prewound flange-less core yarn tubes. While the in-house flanged bobbins typically ran with fewer breaks, the cost to wind, maintain, and schedule around the limited number of reusable flanged bobbins carried significant overhead and opportunity costs. The prewound cardboard bobbins were viewed as the only alternative, even though these packages were more likely to have downtime and uneven lengths, creating lowered efficiencies in their operation.

So Service Thread's technical team spent two days analyzing the process, and we determined that replacing the cardboard cores with flanged bobbins would solve the production issues. To address the winding, maintenance, and scheduling issues associated with the flanged bobbin solution, Service Thread agreed to supply the flanged bobbins ready to use in braiding.

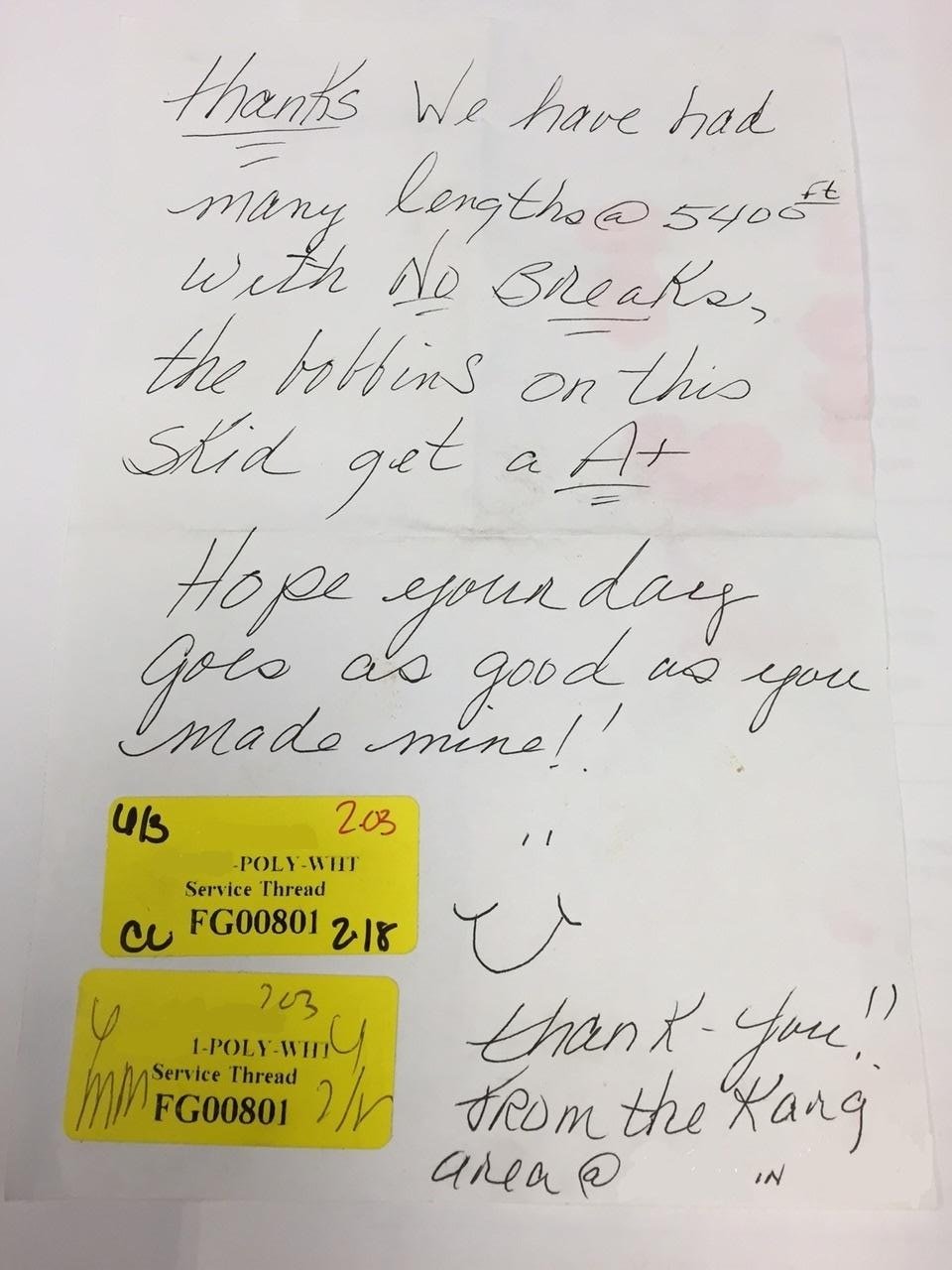

As expected, the problems from the product and process disappeared. Even better, we received this note from the karg braider operators to our winding operators in the returnable bobbin pallet:

"Thanks - We have had many lengths @ 5400 ft with NO BREAKS, the bobbins on this skid get an A+. Hope your day goes as good as you made mine! :) Thank you! - From the Karg Area"

As this experience shows, working together with the right supplier and a willingness to examine both the product and the process leads to major success in solving tough issues. As a manufacturing company that supplies industrial hose manufacturers, Service Thread appreciates the challenges you face in your manufacturing operation - because we face them too!

Download our guide below for helpful tips on best practices and the latest processing tools available to help control yarn tension and other variables that can affect the application of binders, ripcord and strength member into your manufacturing process.