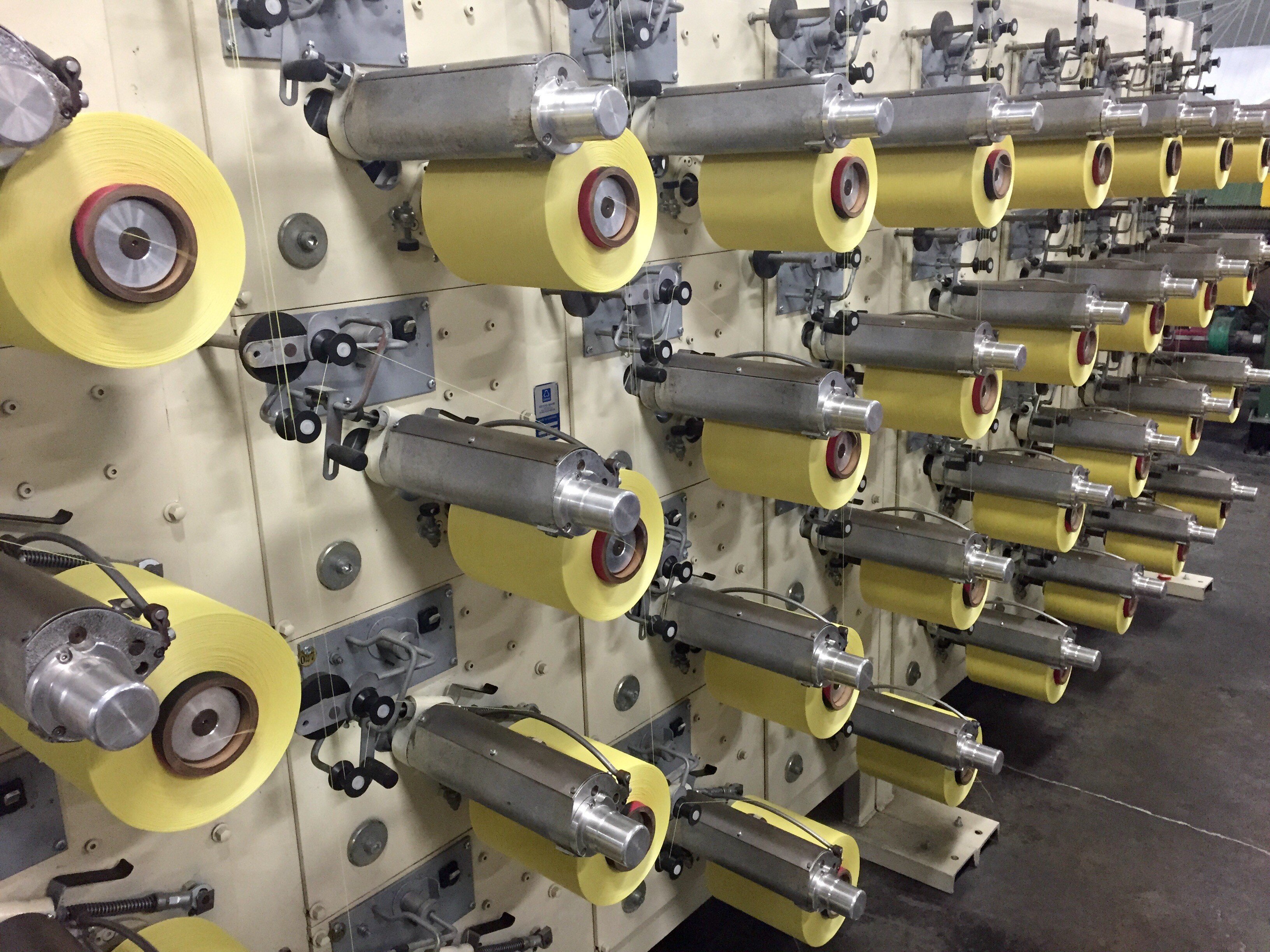

Because continuous multifilament polyester yarns are used in a wide variety of applications and conditions, polyester yarn manufacturers are required to have diverse product portfolios to accommodate them, including yarns in a wide denier range with various physical properties.

Read moreBest Polyester Type for Your Application

- By Service Thread

- 04/07/21

- Industrial Yarn, Polyester, Specifications

- 0 Comments

- By Service Thread

- 10/09/20

- 0 Comments

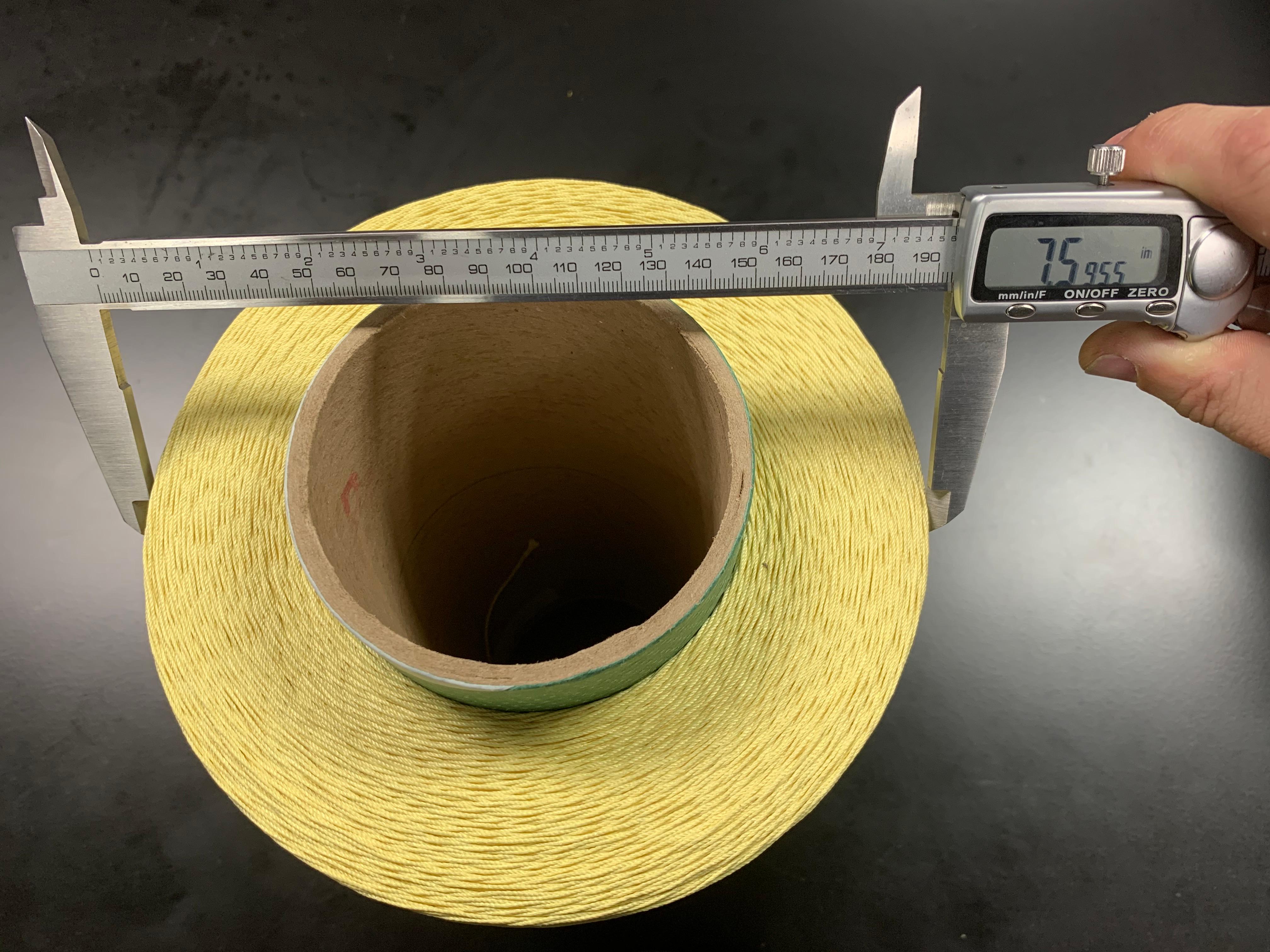

Hose manufacturing partners running high tenacity polyester, nylon and para-aramid yarns all strive for one thing: lower manufacturing costs. There are many cost cutting methods, but the most effective are automation and faster line speeds. Faster line speeds often depend on equipment capabilities, design and material supply.

Read more- By Dane Hatcher

- 09/15/20

- 0 Comments

You can determine sewing speed without using any type of specialized tools. Simply follow the steps outlined below.

Read more- By Ryne Bullock

- 09/09/20

- 0 Comments

The tubes and packages you choose for your industrial yarn and thread can have a big impact on your production efficiency. They affect your process, your ability to operate at high speeds, your rate of slowdowns, your overall productivity, and ultimately your success as a company.

Read more- By Service Thread

- 06/29/20

- 0 Comments

When you buy an electric motor, what is often unseen when handling it is the work that goes into helping extend its life by securing the end coils of windings. This process is called stator lacing. Tightly lacing the coils adds stability and helps protect the windings from vibration, which can cause fatigue and shorten a motor’s life. It also holds electronic, thermal, and other sensory devices in place during the dipping and baking process.

Service Thread’s round lacing cords are available in polyester, nylon, and para-aramid materials such as DuPont™ Kevlar® material. These are cabled constructions, typically three or sometimes four-ply, which offer a round cross-section. Round twisted sizes in nylon and polyester cords can range from number 138 to 690 (tex 135 to 700), offering minimum breaking strengths in the range of 18 to 100 pounds.

However, most common round twisted sizes are number 346 (tex 350), number 415 (tex 400), number 554 (tex 600), and number 690 (tex 700), which offer minimum breaking strengths in the range of 45 to 100 pounds. Round twisted lacing cords number 138 to 690 (tex 135 to 700) will have a diameter between about .01 to .05 inches, while the diameter of most common lacing cords will be .035 inches plus or minus about 15%.

Flat number 554 (tex 600) nylon lacing tape is also a popular choice. Being wider than round twisted thread, it will spread the stress over the coil surface during winding and tying rather than having it located at a small radius. Flat tape also offers increased grip due to its larger surface area.

Round thread can be laced evenly from large supply packages of more than or equal to 10 pounds. Flat constructions are typically rolled to prevent any twisting of the tape. Round twisted lacing cords are much preferred over cable ties, which turn brittle over time through oxidation and break and leave sharp edges which can cut installers’ hands when reaching into confined spaces.

Lacing cords may have some physical requirements, depending on the motor design and coil assembly.

- By Service Thread

- 05/19/20

- 2 Comments

Bonded thread size is communicated in various ways, mainly by ticket number and tex size. Although it’s easy to get caught up in the lingo and confuse the two, the ticket number and tex size are distinct characteristics of a bonded thread.

Read more- By Eric Shippee

- 05/07/20

- 0 Comments

Anyone who works with industrial fabrics knows DuPont™ Kevlar® has a reputation for being one of the world’s toughest fabrics. However, it’s sometimes criticized for being impossible to dye. This isn’t completely true.

Read more- By Service Thread

- 08/09/19

- 2 Comments

To understand twist contraction, think about a ship’s mooring rope. It’s a large, thick rope with thousands of yarns braided and twisted inside. Try to lift a section of the rope, and you’ll find it’s quite heavy.

Read more- By Steve Zande

- 04/08/19

- 0 Comments

The Berry Amendment was passed in 1941 to promote the use of U.S.-sourced materials in military uses. It primarily covers tools, food, and textiles for use at home and abroad in military operations. The amendment outlines specific rules that govern how these goods are produced.

Read more- By Steve Zande

- 03/14/19

- 1 Comment

If you’ve come across the term Cotton Count and were a bit confused, you’re not alone. The terminology of the yarn and thread industry can be tricky.

Read moreBest Polyester Type for Your Application

- By Service Thread

- 04/07/21

- Industrial Yarn, Polyester, Specifications

- 0 Comments

Because continuous multifilament polyester yarns are used in a wide variety of applications and conditions, polyester yarn manufacturers are required to have diverse product portfolios to accommodate them, including yarns in a wide denier range with various physical properties.

Read moreOlder Posts

Lower Manufacturing Costs By Increasing Hose Production Line Speeds

- By Service Thread

- 10/09/20

- 0 Comments

Hose manufacturing partners running high tenacity polyester, nylon and para-aramid yarns all strive for one thing: lower manufacturing costs. There are many cost cutting methods, but the most effective are automation and faster line speeds. Faster line speeds often depend on equipment capabilities, design and material supply.

Read moreYou can determine sewing speed without using any type of specialized tools. Simply follow the steps outlined below.

Read moreThe tubes and packages you choose for your industrial yarn and thread can have a big impact on your production efficiency. They affect your process, your ability to operate at high speeds, your rate of slowdowns, your overall productivity, and ultimately your success as a company.

Read moreWhen you buy an electric motor, what is often unseen when handling it is the work that goes into helping extend its life by securing the end coils of windings. This process is called stator lacing. Tightly lacing the coils adds stability and helps protect the windings from vibration, which can cause fatigue and shorten a motor’s life. It also holds electronic, thermal, and other sensory devices in place during the dipping and baking process.

Service Thread’s round lacing cords are available in polyester, nylon, and para-aramid materials such as DuPont™ Kevlar® material. These are cabled constructions, typically three or sometimes four-ply, which offer a round cross-section. Round twisted sizes in nylon and polyester cords can range from number 138 to 690 (tex 135 to 700), offering minimum breaking strengths in the range of 18 to 100 pounds.

However, most common round twisted sizes are number 346 (tex 350), number 415 (tex 400), number 554 (tex 600), and number 690 (tex 700), which offer minimum breaking strengths in the range of 45 to 100 pounds. Round twisted lacing cords number 138 to 690 (tex 135 to 700) will have a diameter between about .01 to .05 inches, while the diameter of most common lacing cords will be .035 inches plus or minus about 15%.

Flat number 554 (tex 600) nylon lacing tape is also a popular choice. Being wider than round twisted thread, it will spread the stress over the coil surface during winding and tying rather than having it located at a small radius. Flat tape also offers increased grip due to its larger surface area.

Round thread can be laced evenly from large supply packages of more than or equal to 10 pounds. Flat constructions are typically rolled to prevent any twisting of the tape. Round twisted lacing cords are much preferred over cable ties, which turn brittle over time through oxidation and break and leave sharp edges which can cut installers’ hands when reaching into confined spaces.

Lacing cords may have some physical requirements, depending on the motor design and coil assembly.

What Is the Difference Between Ticket Size and Tex Size for Bonded Thread?

- By Service Thread

- 05/19/20

- 2 Comments

Bonded thread size is communicated in various ways, mainly by ticket number and tex size. Although it’s easy to get caught up in the lingo and confuse the two, the ticket number and tex size are distinct characteristics of a bonded thread.

Read moreCan Kevlar® Be Dyed?

- By Eric Shippee

- 05/07/20

- 0 Comments

Anyone who works with industrial fabrics knows DuPont™ Kevlar® has a reputation for being one of the world’s toughest fabrics. However, it’s sometimes criticized for being impossible to dye. This isn’t completely true.

Read moreTo understand twist contraction, think about a ship’s mooring rope. It’s a large, thick rope with thousands of yarns braided and twisted inside. Try to lift a section of the rope, and you’ll find it’s quite heavy.

Read moreUnderstanding the Berry Amendment and its Exceptions Related to Textiles and Sewing

- By Steve Zande

- 04/08/19

- 0 Comments

The Berry Amendment was passed in 1941 to promote the use of U.S.-sourced materials in military uses. It primarily covers tools, food, and textiles for use at home and abroad in military operations. The amendment outlines specific rules that govern how these goods are produced.

Read moreWhat is Cotton Count?

- By Steve Zande

- 03/14/19

- 1 Comment

If you’ve come across the term Cotton Count and were a bit confused, you’re not alone. The terminology of the yarn and thread industry can be tricky.

Read more