Thickness (or diameter) is one of the basic physical properties of textile materials. In certain industrial applications, the thickness may require rigid control within specified limits. Bulk and warmth properties of textile materials are often estimated from their thickness values, and thickness is also useful in measuring some performance characteristics, such as before and after abrasion and shrinkage.

Thickness (or diameter) is one of the basic physical properties of textile materials. In certain industrial applications, the thickness may require rigid control within specified limits. Bulk and warmth properties of textile materials are often estimated from their thickness values, and thickness is also useful in measuring some performance characteristics, such as before and after abrasion and shrinkage.

Not to be confused with thickness, the width of a yarn or tape is also a very important measurement. The width of a material helps to determine how much yarn coverage there will be when a material is laid flat on another surface. Width is an important factor when determining the coverage of yarn in a bundled cable, determining the needed pitch for a braided or spirally wrapped hose, or when calculating pore size and fabric density in woven fabrics. These methods cover the determination of thickness and width of tape, monofilament, multifilament and spun yarns, either single or cabled, natural or colored.

Test Procedure for Measuring the Diameter of Yarn and Thread

Tools Needed:

Tools Needed:

- Digital Thickness Gauge with 10mm diameter presser foot/feeler

Procedure:

-

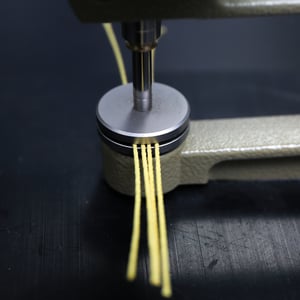

Cut four short 3” length samples of material and lay them parallel to each other on presser foot. Materials should be spaced closely to minimize compression and spread of the fibers which can result in a less accurate measurement

-

Lower the feeler/presser foot onto the material being measured

-

Raise and lower the presser foot three times onto the sample and record the measurement

-

Average the results from the 3 readings

Procedure for Measuring the Width of Yarns and Tapes

Tools Needed:

Requirements:

The material will be measured in a pre-tensioned state to determine accurate width

Procedure:

- Determine pre-tension weight to be used - typically 0.05 grams per denier

• e.g. for 1000 denier = 1000 x 0.05 = 50 g;

-

Cut three 18” samples of material to be tested;

-

Place one end of material in a stationary clamp and the other end of material over a roller or fixed bar;

-

Tension material by attaching determined pretension weight to end over roll, making sure it is suspended in air;

-

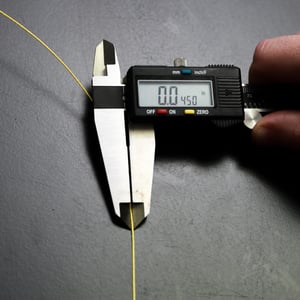

Zero out calipers and carefully set fixed end on edge of material while carefully moving adjustable end against other edge of material,

-

Record 3 measurements at least 1.0” apart;

-

Repeat steps 3 – 6 for remaining 2 samples, and

-

Average results from 3 samples.

As discussed in our previous post, you can also estimate yarn diameter based on the fiber type and denier size however, the above tools and procedures will give you the most accurate measurements for both yarn diameter and yarn.

Contact us if you need help determining the right industrial yarn size and type for your application.